Self-decomposition temporary plugging agent for workover fluid and using method of temporary plugging agent

A technology of workover fluid and self-decomposition, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as difficulty in plugging, and achieve the effect of low preparation equipment requirements, high plugging strength, and excellent fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

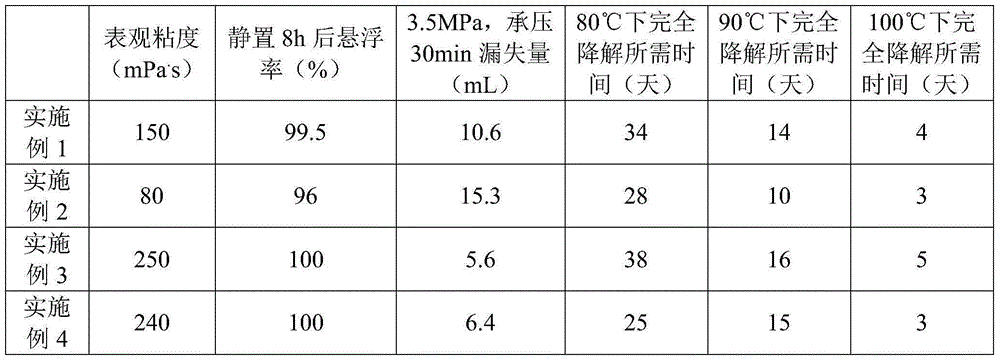

Examples

Embodiment 1

[0029] Self-decomposing temporary plugging agent formula combination: 30 mass parts of polylactic acid ellipsoidal large particles with a particle diameter of about 5 mm, 50 mass parts of polylactic acid small particles with a particle diameter of about 30 mesh, 0.4 mass parts of polylactic acid short fibers with a length of 5 mm and 19.6 parts by mass of polylactic acid superfine powder with an average particle diameter of 300 meshes.

[0030] As mentioned above, the method of using self-decomposing temporary plugging agent for workover fluid is as follows:

[0031] 1) Preparation of thickened workover fluid: under stirring, slowly add 0.5 parts by mass of hydroxypropyl guar gum to 100 parts by mass of clear water, and swell for 30 minutes to obtain a thickened workover fluid;

[0032] 2) Preparation of temporary plugging type workover fluid: under stirring, slowly add polylactic acid short fibers into the thickened workover fluid, disperse for 15 minutes until uniform, add t...

Embodiment 2

[0036] Self-decomposing temporary plugging agent formula combination: 10 parts by mass of polylactic acid ellipsoidal large particles with a particle diameter of about 1 mm, 60 parts by mass of small polylactic acid particles with a particle diameter of about 40 mesh, 0.2 parts by mass of short polylactic acid fibers with a length of 3 mm and 29.8 parts by mass of polylactic acid superfine powder with an average particle diameter of 100 mesh.

[0037] As mentioned above, the method of using self-decomposing temporary plugging agent for workover fluid is as follows:

[0038] 1) Preparation of thickened workover fluid: under stirring, slowly add 0.4 parts by mass of hydroxypropyl guar gum to 100 parts by mass of clear water, and swell for 30 minutes to obtain a thickened workover fluid;

[0039] 2) Preparation of temporary plugging type workover fluid: under stirring, slowly add polylactic acid short fibers into the thickened workover fluid, disperse for 15 minutes until uniform...

Embodiment 3

[0041] Self-decomposing temporary plugging agent formula combination: 40 parts by mass of polylactic acid ellipsoidal large particles with a particle diameter of about 10 mm, 20 parts by mass of small polylactic acid particles with a particle diameter of about 40 mesh, 1 part by mass of short polylactic acid fibers with a length of 10 mm and 39 parts by mass of polylactic acid superfine powder with an average particle diameter of 200 meshes.

[0042] As mentioned above, the method of using self-decomposing temporary plugging agent for workover fluid is as follows:

[0043] 1) Preparation of thickened workover fluid: under stirring, slowly add 0.6 parts by mass of hydroxypropyl guar gum to 100 parts by mass of clear water, and swell for 30 minutes to obtain a thickened workover fluid;

[0044] 2) Preparation of temporary plugging type workover fluid: under stirring, slowly add polylactic acid short fibers into the thickened workover fluid, disperse for 15 minutes until uniform,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com