a steel reel

A technology of steel coils and outer sleeves, applied in the field of steel coils, can solve the problems of scratches, scratches, loose coils, unadjustable size, etc., and achieves the effect of not easy to unravel and less loose.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

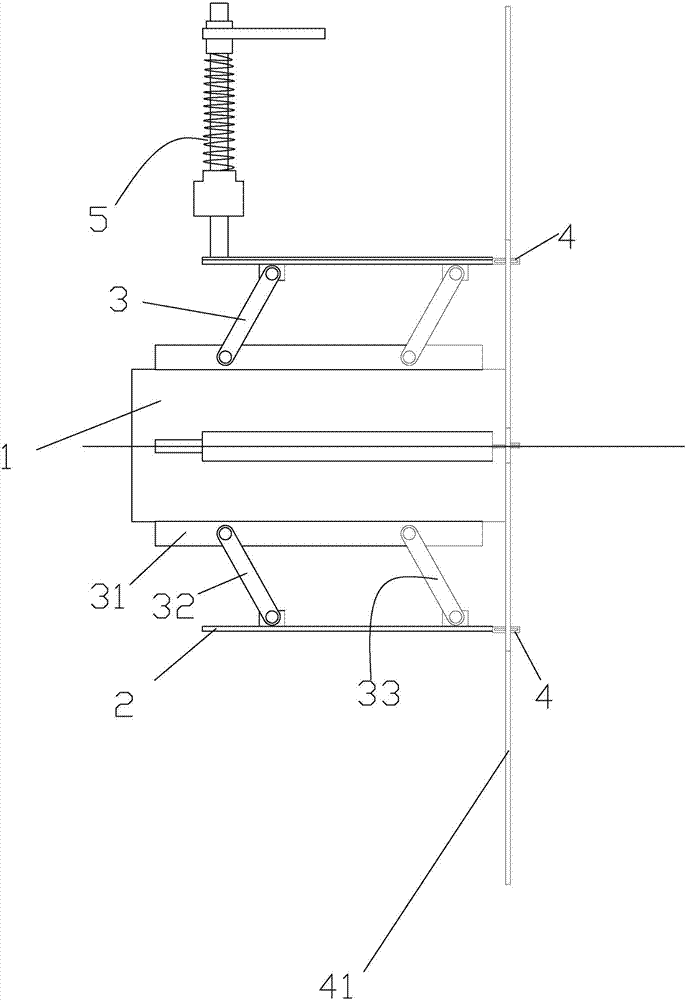

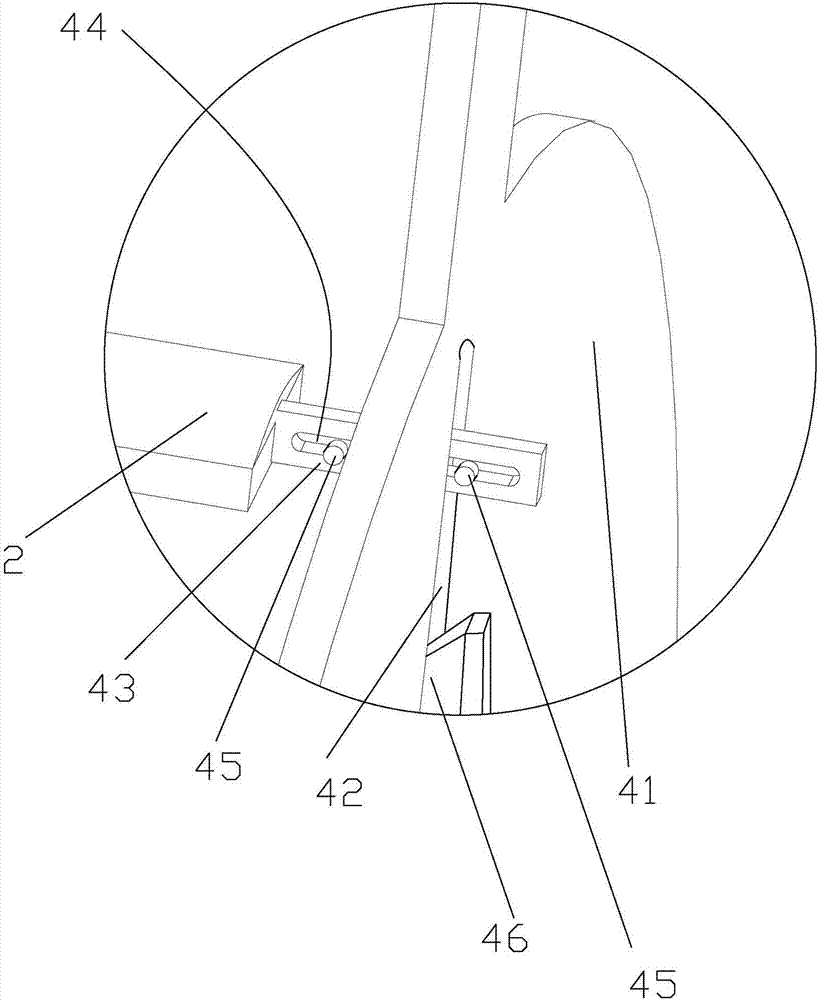

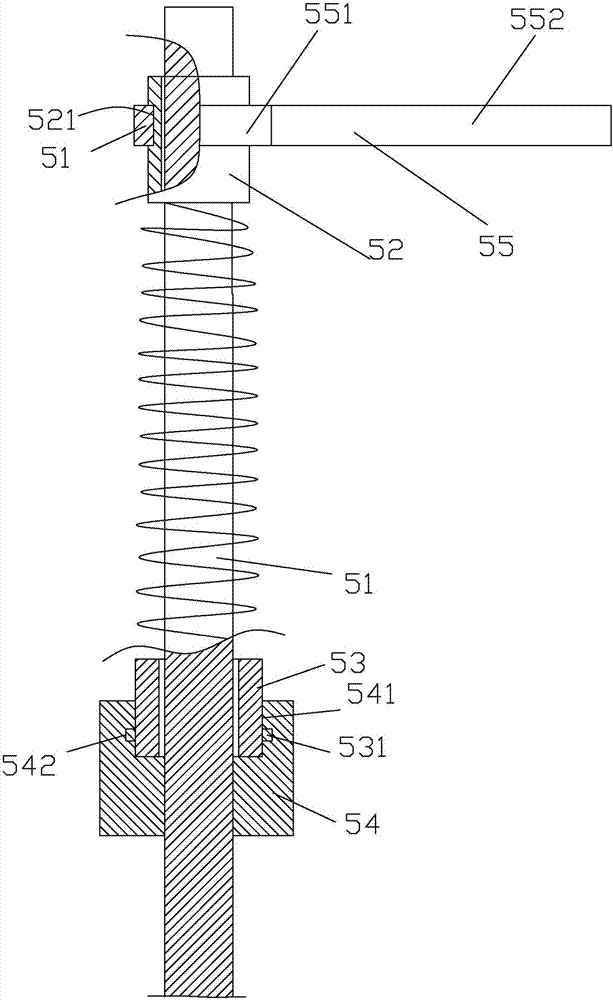

[0025] Example: such as Figure 1-Figure 3 As shown, a steel reel includes a rotary shaft 1, a plurality of winding braces 2 arranged around the rotary shaft 1 and used for winding sound-absorbing panels, and the winding braces 2 are connected to each other through an expansion and contraction mechanism 3. The rotary shaft 1 is connected; the expansion and contraction mechanism 3 includes a base 31 fixed on the rotary shaft 1 , and a second shaft that is hinged to the base 31 and rotates axially relative to the rotary shaft 1 and is arranged parallel to each other. A connecting plate 32 and a second connecting plate 33, the ends of the first connecting plate 32 and the second connecting plate 33 away from the rotary shaft 1 are hingedly arranged with the winding brace 2, and the expansion and contraction mechanism 3 adjusts the first connecting plate 32 , The angle between the second connecting plate 33 and the base 31 realizes expansion and contraction; when the steel reel ne...

Embodiment 2

[0036] Embodiment 2: as Figure 4 As shown, the clamping part 552 is a cylindrical body, the surface of the cylindrical body is vertically provided with a plurality of linearly arranged elastic pressure columns 5521, and the end surface of the elastic pressure columns 5521 is provided with a spherical groove 5522, and the grooves 5522 is provided with a rollable spherical indenter 5523. The spherical pressure head 5522 adjusts the contact point during rolling, and the elastic pressure column 5521 reduces the rigid impact during clamping, reduces the deformation of the board, and effectively protects the board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com