Injectable efficient suspended stable calcium phosphate cement and preparation method and application thereof

A calcium phosphate bone cement, suspension stability technology, applied in dental preparations, pharmaceutical formulations, medical science and other directions, can solve the problems of poor suspension stability, prolonging curing time, reducing the injectability of calcium phosphate bone cement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] A preparation method for injectable high-efficiency suspension-stable calcium phosphate bone cement, comprising the following steps:

[0074] (1) Preparation of injectable high-efficiency suspension stable calcium phosphate bone cement solidification solution

[0075] The stabilizer is added to the non-aqueous phase solution, and the solidified liquid is obtained by ultrasonic dispersion according to the mass ratio of non-aqueous phase solvent:suspension stabilizer=10:(0.1-1).

[0076] Wherein said non-aqueous solvent is at least one of simethicone, propylene glycol, water-soluble silicone oil, glycerin and polyethylene glycol (including one solvent, or a mixed solvent composed of multiple solvents).

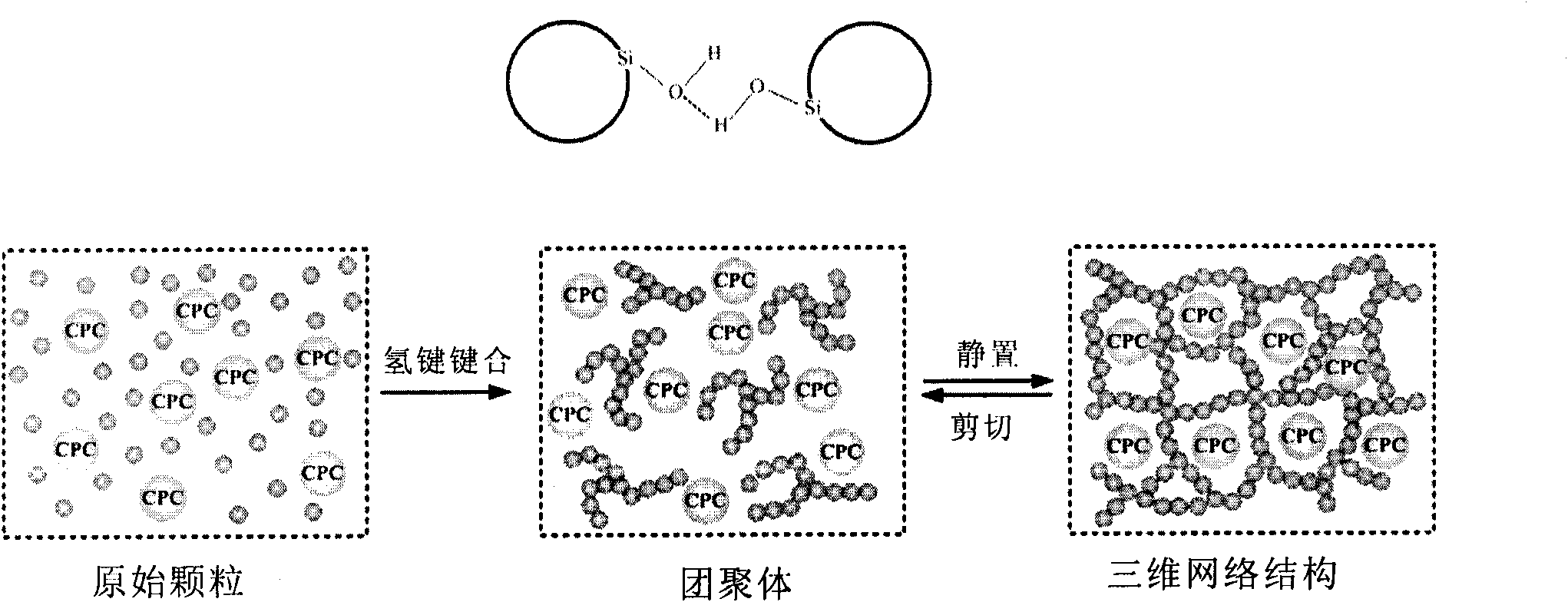

[0077] Wherein said suspension stabilizer is at least one of hydrophilic silicon dioxide, hydrophobic silicon dioxide and surface-modified silicon dioxide. Surface-modified silica refers to fumed silica that has been treated by dry method, wet method or dry heat method. ...

Embodiment 1

[0102] Weigh 10 g of composite calcium phosphate salt (ingredients: calcium hydrogen phosphate, tetracalcium phosphate and hydroxyapatite) powder with an average particle size less than 10 μm, and 1 g of iodoform, and dry mix to form a solid phase powder;

[0103] Weigh 0.15 g of hydrophilic fumed silica (average particle diameter: 30 nm), pour it into a beaker containing 6 g of propylene glycol, and stir fully so that the hydrophilic fumed silica is fully dissolved in propylene glycol to obtain a solidified solution.

[0104] Pour the solidified liquid into the powder, disperse evenly in the vessel, and mix evenly with a dental spatula to obtain a non-aqueous calcium phosphate bone cement with good developability and injectability (referred to as "bone cement paste").

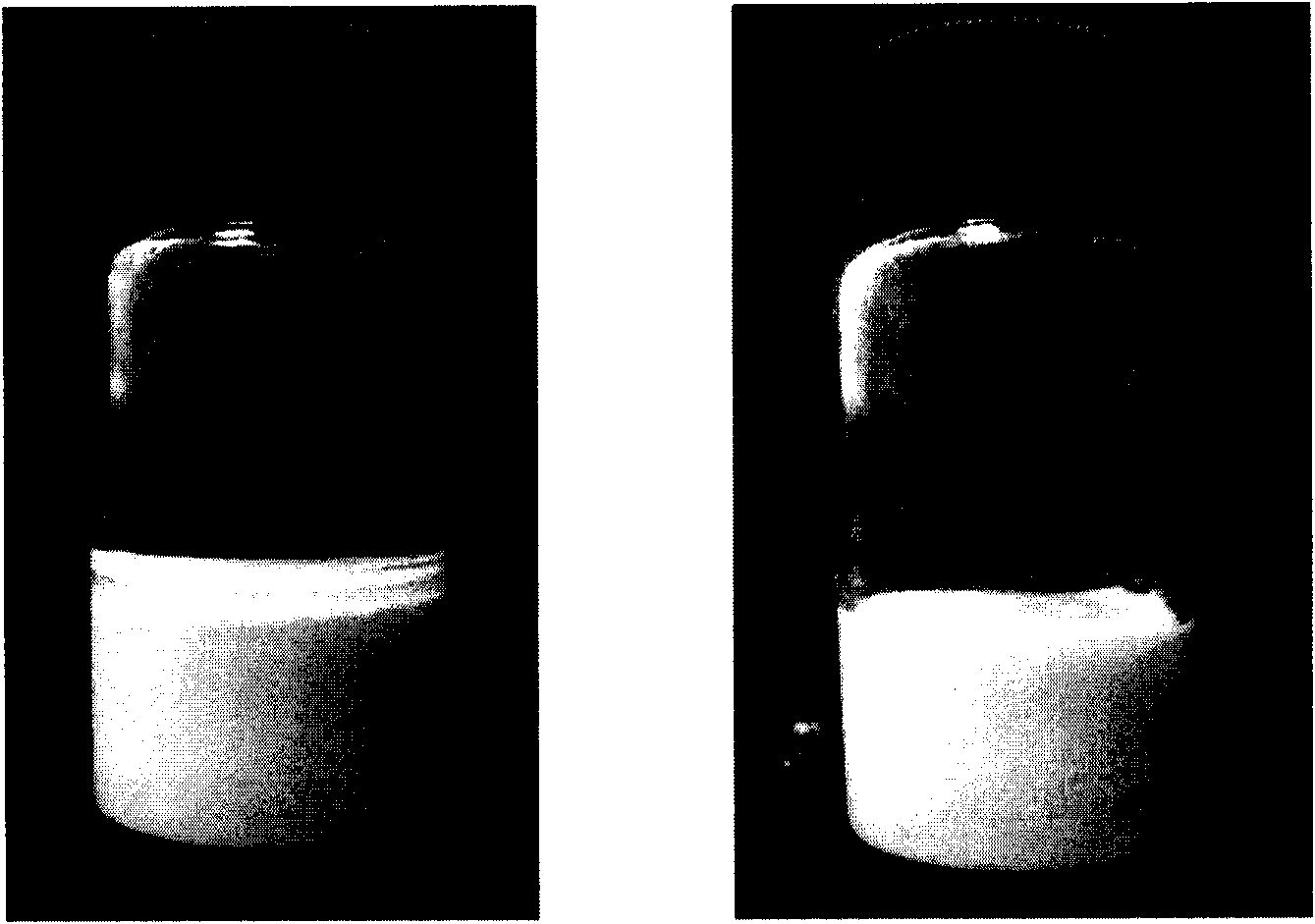

[0105] The prepared non-aqueous calcium phosphate bone cement was filled into a 5ml syringe and left to stand. The time elapsed from the beginning of standing to the time when the bone cement in the syringe cl...

Embodiment 2

[0112] Weigh 10 g of composite calcium phosphate salt (ingredients: calcium hydrogen phosphate, tetracalcium phosphate and hydroxyapatite) powder with a particle size less than 10 μm, 1 g of strontium chloride, and 0.15 g of hydrophobic fumed silica (average particle size of 20 nm), Dry mixing; pour into a beaker containing 6g of simethicone oil, and ultrasonically disperse to fully dissolve the hydrophobic fumed silicon dioxide into the simethicone oil, disperse evenly in the vessel, and mix evenly with a dental preparation knife to obtain Non-aqueous calcium phosphate bone cement with good visualization and injectability (see appendix image 3 ).

[0113] The prepared non-aqueous calcium phosphate bone cement was filled into a 5ml syringe and left to stand. The time elapsed from the beginning of standing to the time when the bone cement in the syringe clearly delaminated was taken as the suspension stability time of the system.

[0114] The bone cement paste prepared above...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com