Temperature-resistant and salt-resistant filtrate reducer for drilling fluid, and preparation method thereof

A technology of fluid loss reducer and drilling fluid, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor temperature resistance and difficulty in application, and achieve enhanced rigidity, good salt resistance, and improved thermal stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

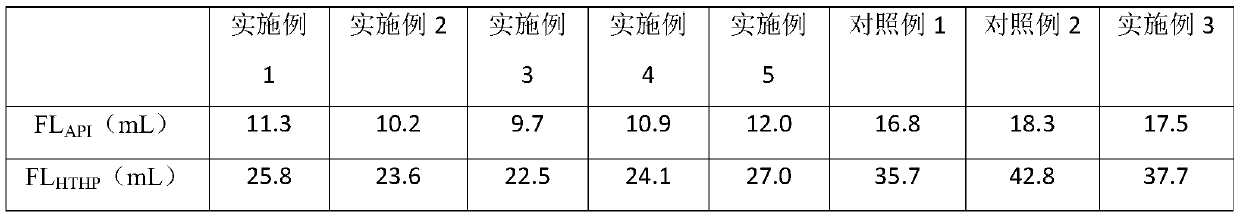

Examples

Embodiment 1

[0031] The temperature-resistant and salt-resistant fluid loss reducer for drilling fluid in this embodiment includes: in parts by weight, 20 parts of modified rice husk powder, 20 parts of modified bagasse, 20 parts of modified sulfonated lignite resin, and 10 parts of acrylamide 10 parts of acrylic acid, 10 parts of 2-acrylamido-2-methylpropanesulfonic acid, 10 parts of maleic anhydride, 5 parts of N-vinylpyrrolidone and 10 parts of dimethyl diallyl ammonium chloride.

[0032] Wherein, the preparation steps of the modified rice husk powder include: adding the rice husk to the culture solution, adding disodium hydrogen phosphate-citric acid buffer solution to the culture solution, adjusting the pH to 3, adding white rot fungus, and adding the white rot fungus at a temperature of 30° C. After reacting for 36 hours, take it out, dry it and crush it to a particle size of 50 mesh to obtain modified rice husk powder; wherein, the mass ratio of rice husk, culture solution and white ...

Embodiment 2

[0046] The temperature-resistant and salt-resistant fluid loss reducer for drilling fluid in this embodiment includes: in parts by weight, 30 parts of modified rice husk powder, 30 parts of modified bagasse, 30 parts of modified sulfonated lignite resin, and 20 parts of acrylamide 20 parts, 20 parts of acrylic acid, 15 parts of 2-acrylamido-2-methylpropanesulfonic acid, 15 parts of maleic anhydride, 10 parts of N-vinylpyrrolidone and 10 parts of dimethyl diallyl ammonium chloride.

[0047] Wherein, the preparation steps of modified rice husk powder, modified bagasse and modified sulfonated lignite resin are the same as those in Example 1.

[0048] The preparation method of the temperature-resistant and salt-resistant fluid loss additive for drilling fluid in this embodiment is consistent with the preparation method of the temperature-resistant and salt-resistant fluid loss additive for drilling fluid in Example 1.

Embodiment 3

[0050] The temperature-resistant and salt-resistant fluid loss reducer for drilling fluid in this embodiment includes: by weight, 35 parts of modified rice husk powder, 35 parts of modified bagasse, and 40 parts of modified sulfonated lignite resin 25 parts of acrylamide, 25 parts of acrylic acid, 20 parts of 2-acrylamido-2-methylpropanesulfonic acid, 17 parts of maleic anhydride, 15 parts of N-vinylpyrrolidone and dimethyl diallyl chloride Ammonium 12 parts. .

[0051] Wherein, the preparation steps of the modified rice husk powder include: adding the rice husk to the culture solution, adding disodium hydrogen phosphate-citric acid buffer solution to the culture solution, adjusting the pH to 3, adding white rot fungus, and adding the white rot fungus at a temperature of 32°C. After reacting for 45 hours, take it out, dry it and crush it to a particle size of 50 mesh to obtain modified rice husk powder; wherein, the mass ratio of rice husk, culture solution and white rot fung...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com