Modification method for dietary fiber of black fungus

A technology of dietary fiber and black fungus, applied in the functions of food ingredients, food extraction, food science and other directions, can solve the problems of high viscosity, unfavorable enzyme molecular fluidity and diffusion, increased difficulty in the extraction and preparation process, and increased viscosity of the extraction system, etc. To achieve the effect of loose macromolecule structure of dietary fiber, good sensory properties, and improvement of cell wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1 Materials and reagents

[0033] Black fungus (provided by Hangzhou Huadan Agricultural Products Co., Ltd.). Before use, dry in an oven at 50°C, pulverize, and sieve samples with a mesh size of 40-60 mesh for later use.

[0034] Phenol, concentrated sulfuric acid, DPPH, absolute ethanol are analytically pure;

[0035] Cellulase (activity 10000u / g) was purchased from Shanghai Aladdin Biochemical Technology Co., Ltd.

[0036] 2 experimental equipment

[0037] Grinder, AL04 electronic balance, HH-2 water bath, drying oven, centrifuge, agitator, spectrophotometer, ultrasonic breaker

[0038] 3 Experimental methods

[0039] 3.1 Preparation of black fungus DF

[0040] Crush black fungus, pass through a 40-60 mesh sieve, take 40g of black fungus coarse powder, mix with 2000g of deionized water, stir and extract at 80°C for 4 hours, centrifuge for 30min (4000r / min), discard the supernatant, and The slag was washed repeatedly with deionized water, vacuum-dried, pulverized...

Embodiment 2

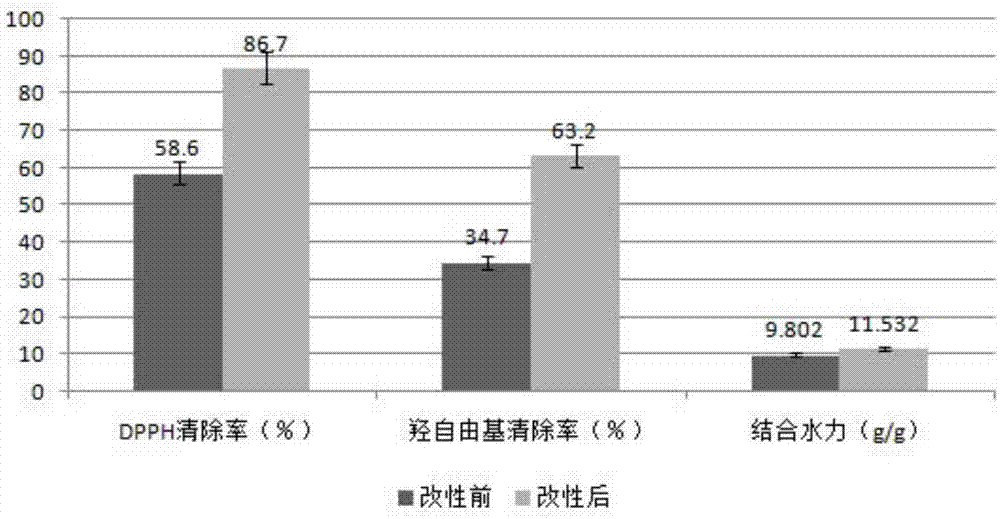

[0111] The experimental operation is the same as in Example 1, the difference is that 20g of black fungus DF is taken, deionized water is added according to the ratio of material to liquid at 1:50, and then 120ml of cellulase (0.9%) is added (the mass ratio of black fungus DF is 5.4 %), put it into an ultrasonic breaker, and ultrasonicate it for 10 minutes under the conditions of ultrasonic frequency 30kHz, power 4W, and treatment temperature 50°C, then take it out and put it in a water bath to continue enzymatic hydrolysis for 260 minutes, and then make up the ratio of solid to liquid to 1: 110, put it into the ultrasonic breaker again, and ultrasonicate for 20 minutes under the condition of ultrasonic frequency 30kHz and power 4W. The average value of total sugar content is 12.35%, the scavenging rate for DPPH·91.21%, the scavenging rate for hydroxyl radicals is 68.41%, and the binding water capacity is 22.84g / g.

Embodiment 3

[0113] The experimental operation is the same as in Example 1, except that 20g of black fungus DF is taken, deionized water is added according to the ratio of material to liquid at 1:50, and then 130ml of cellulase (0.9%) is added (the mass ratio of black fungus DF is 5.85%) %), put it into an ultrasonic breaker, and ultrasonicate for 5 minutes at an ultrasonic frequency of 20kHz, a power of 4W, and a treatment temperature of 50°C, then take it out and put it in a water bath to continue enzymatic hydrolysis for 265 minutes, and then make up the ratio of solid to liquid to 1: 110, put it into the ultrasonic breaker again, and ultrasonicate for 25 minutes under the condition of ultrasonic frequency 20kHz and power 4W. The average value of total sugar content is 12.13%, the scavenging rate for DPPH·91.21%, the scavenging rate for hydroxyl radicals is 68.31%, and the binding water capacity is 24.35g / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com