Application of chitosan quaternary ammonium salt to wastepaper recirculation

A chitosan quaternary ammonium salt and waste paper making technology, which is applied in paper making, textiles and paper making, paper and other directions, can solve the problems affecting the normal operation of paper machines and product quality, weakening the effect of auxiliary agents, etc. Significant effects of improving dry and wet strength and collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 200g of absolute dry waste newspaper and tear it into pieces of 20mm×20mm. Put the absolutely dry waste paper in the barrel, add 3g of NaOH particles weighed, NaOH 2 SiO 3 Solid 4g and surfactant are dissolved with 200ml of water required for pulping. Among them, the slurry concentration is 10%, and the required water volume is calculated to be 2000ml, and then poured into a bucket, stirred and moistened, and aged for 10 minutes.

[0028] After the aging is completed, pour the remaining 18,000ml of water required for pulping, and the pulp in the barrel into the pulper, control the pulping temperature at about 55°C, and crush for 10 minutes. Part H added during pulping 2 o 2 , The ink stripping effect is good.

[0029] Add 2000ml of water used for flotation in advance in the flotation tank, and the flotation concentration is 1%, and the calculation requires 18000ml of water. After the pulping is completed, move all the slurry to the flotation tank as soon as p...

Embodiment 2

[0038] (1) Slurry preparation: waste newsprint was deinked by flotation, and after PFI beating, 400ml of waste paper slurry with a concentration of 0.5% and 2g dry pulp was prepared. The 0.5% dry pulp waste paper slurry here means that the weight ratio of water and shredded paper is 100:0.5.

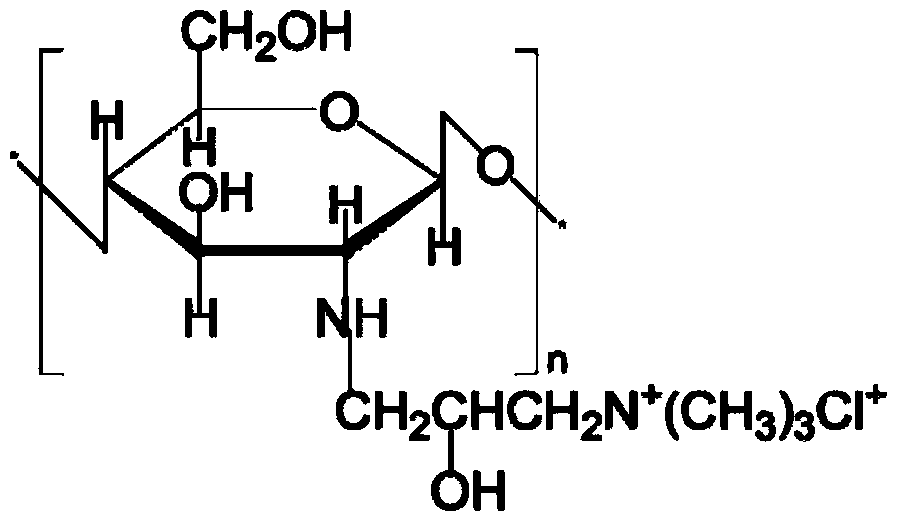

[0039] (2) Capture of anionic garbage: waste paper slurry is placed on DDJ-2, using a 200-mesh filter, fully stirred at 750r / min, adding 0.002g of chitosan quaternary ammonium salt, and filtering under stirring conditions .

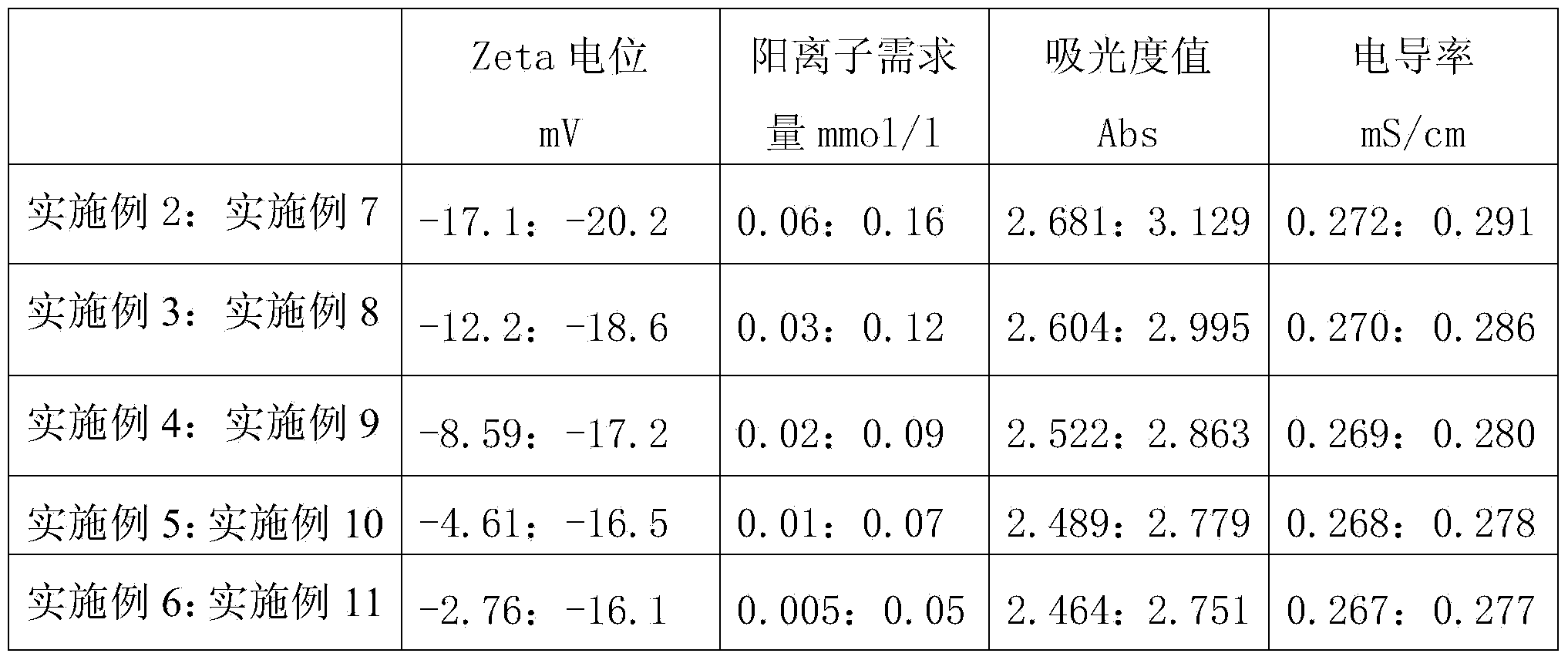

[0040] (3) Comparison of anion garbage collection effects: Take the first 100ml of filtrate, take the supernatant after high-speed centrifugation, and measure its Zeta potential, cation demand, conductivity, and filtrate absorbance.

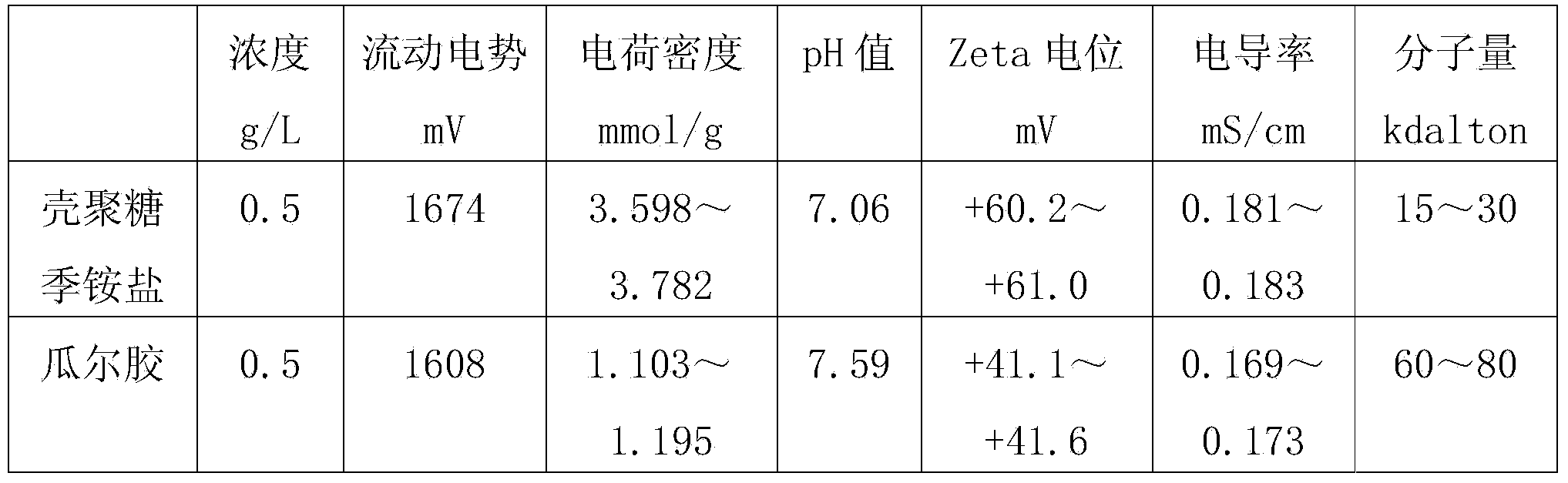

[0041] (4) Comparison of anionic garbage collectors: prepare a solution with a concentration of 0.5g / l, and comprehensively compare the streaming potential, charge density, Zeta potential, pH value, conductivity, molecular weight and ...

Embodiment 3-6

[0043] Complete Example 2 according to the same steps as described, but the amount of chitosan quaternary ammonium salt added in step (2) in Examples 3, 4, 5, and 6 is 0.004g, 0.006g, 0.008g, 0.010g .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com