High-strength pervious concrete material and preparation method thereof

A permeable concrete, high-strength technology, applied in the field of building materials, can solve the problem of less involvement of high-strength permeable concrete, and achieve the effects of being conducive to environmental protection, good chemical stability, and improving compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

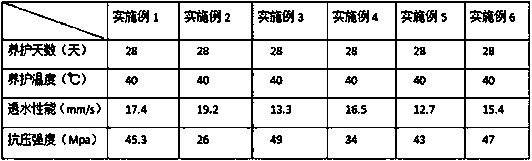

Examples

Embodiment 1

[0029] Embodiment 1 (the following components are parts by weight)

[0030] A high-strength permeable concrete material, including 1400 parts of limestone, 400 parts of G-grade high sulfate-resistant oil well cement, 3.2 parts of sodium sulfomethyl gallate tannate, 3.2 parts of plasma-treated cellulose fiber, and 110 parts of water.

Embodiment 2

[0032] A high-strength permeable concrete material, comprising 1,500 parts of limestone, 400 parts of G grade high sulfate-resistant oil well cement, 3.2 parts of sodium sulfomethyl gallic tannate, 3.2 parts of plasma-treated cellulose fiber, and 110 parts of water.

Embodiment 3

[0034] A high-strength permeable concrete material, including 1400 parts of limestone, 500 parts of G-grade high sulfate-resistant oil well cement, 4 parts of sodium sulfomethyl gallic tannate, 4 parts of plasma-treated cellulose fiber, and 110 parts of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com