Underwater oil-adsorption-resistant oil-adhesion-resistant material, membrane, and coating, and preparation method and application thereof

An adhesive material, oil adsorption technology, applied in chemical instruments and methods, coatings, membranes, etc., can solve problems such as loss of special wettability, anti-oil pollution function or oil-water separation function, adhesion and pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] Also provided in some embodiments is a method of preparing an oil-adherent film or coating, comprising:

[0049] Provide a polymer solution, including a polymer compound (polymer raw material) containing an ionizable hydrophilic group;

[0050] Coating or impregnating the substrate with the polymer solution, coating or adsorbing the polymer compound on the substrate to form a polymer compound layer;

[0051] Fully impregnating the polymer compound layer with an alkaline solution to invert the phase of the polymer compound and ionize the hydrophilic groups in the polymer compound, thereby forming the film or coating on the substrate.

[0052] In the foregoing embodiments, by fully impregnating the polymer compound layer with an alkaline solution, the organic solvent dissolving the polymer compound can be diffused into the alkaline solution, but the polymer compound is not compatible with the basic poor solvent. Dissolution and precipitation forming, so that the polymer ...

Embodiment 1

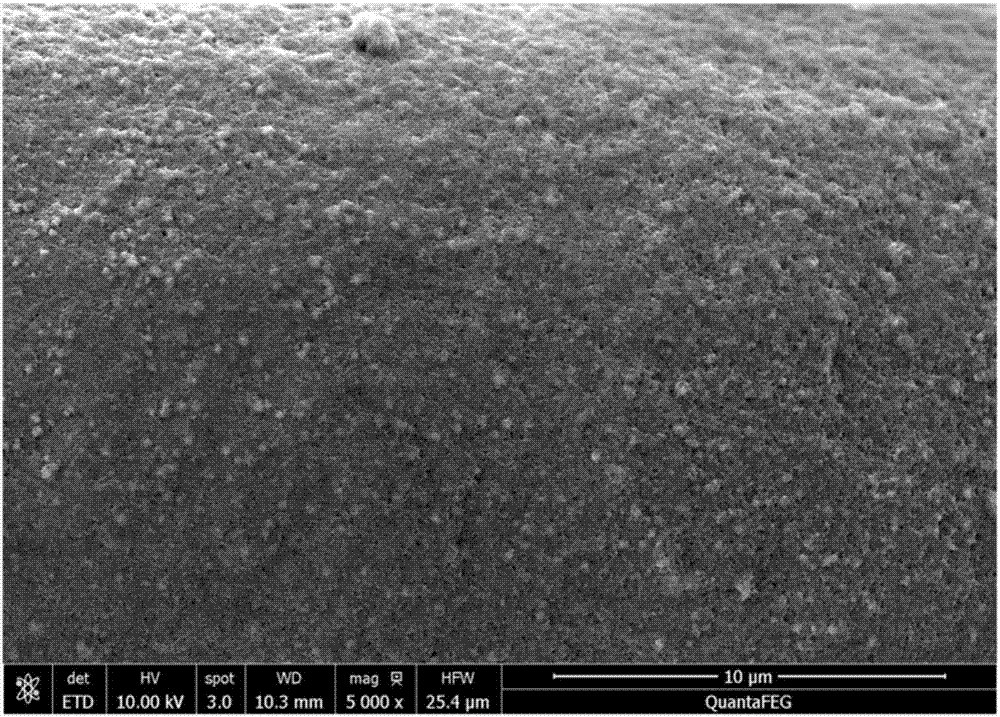

[0082] Example 1: Dissolve sulfonated polyethersulfone in N,N-dimethylformamide to prepare a polymer raw material solution with a concentration of 10 wt%. The above-mentioned polymer raw material solution is evenly coated on the surface of a clean glass substrate by a scraping method, and then transferred into an aqueous solution of sodium hydroxide with a concentration of 0.01mol / L for phase inversion and the reaction of generating ionized hydrophilic functional groups. After 10 minutes, it was taken out from the aqueous sodium hydroxide solution, and the excess sodium hydroxide was washed away with clear water to obtain the finished oil-resistant adhesion material (separation membrane). Its optical photo and surface appearance can be found in figure 1 with figure 2 , its underwater oil contact angle is 166° (see figure 1 ), its underwater oil adhesion is about 0μN (see image 3 ).

Embodiment 2

[0083] Example 2: Dissolve sulfonated polyethersulfone in N,N-dimethylformamide to prepare a polymer raw material solution with a concentration of 10%. Apply the above-mentioned polymer raw material solution evenly on the surface of a clean glass substrate by the scraping method, then transfer it to a water bath for phase inversion, take it out after 10 minutes and transfer it to an aqueous solution of sodium hydroxide with a concentration of 0.1mol / L for formation Ionize the reaction of the hydrophilic functional group, take it out of the sodium hydroxide aqueous solution after 5 minutes, wash off the excess sodium hydroxide with water, and obtain the finished oil-resistant adhesion separation membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com