A kind of goggles and preparation method thereof

A technology for goggles and lenses, applied in glasses/goggles, instruments, optics, etc., can solve the problems of inability to achieve anti-ultraviolet, anti-glare, anti-infrared, anti-laser, single function, low structural strength, etc. Combat effectiveness, enhanced visual effects, high structural strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1, the making of goggles

[0057] (1) Production of lenses

[0058] 1) Fabrication of the substrate

[0059] The overall process environment is carried out in the purification workshop, and the workshop maintains positive pressure.

[0060] Using LQ3187 polycarbonate with a mass ratio of 1:0.08:0.1 as the main material, DP1-1821 and PET3117 as auxiliary materials, dry the main and auxiliary materials at 110°C for 9 hours to make the water content below 0.015%, and mix the main and auxiliary materials at 270°C Carry out 12 hours in the high-temperature melting furnace, melt and mix to obtain a stable molten mixture, the constant temperature of the feeding pipe is about 110°C, the temperature of the mold is kept between 90-110°C, filter, and inject the filtered liquid mixed polycarbonate The pressure is controlled at 110-130MPa, the depth of the vent hole is less than 0.08mm, injection molding, and annealed in the stress relief furnace for 2.5h to obtain the su...

Embodiment 2

[0075] Embodiment 2, goggles performance test

[0076] Anti-fragmentation performance

[0077] Referring to GJB4300A-2012, the anti-1.1g simulated fragment V50 value of the lens is 217.8m / s.

[0078] Flame retardant

[0079] According to QB / T 2506-2017, when the steel rod is removed, the lens does not continue to burn.

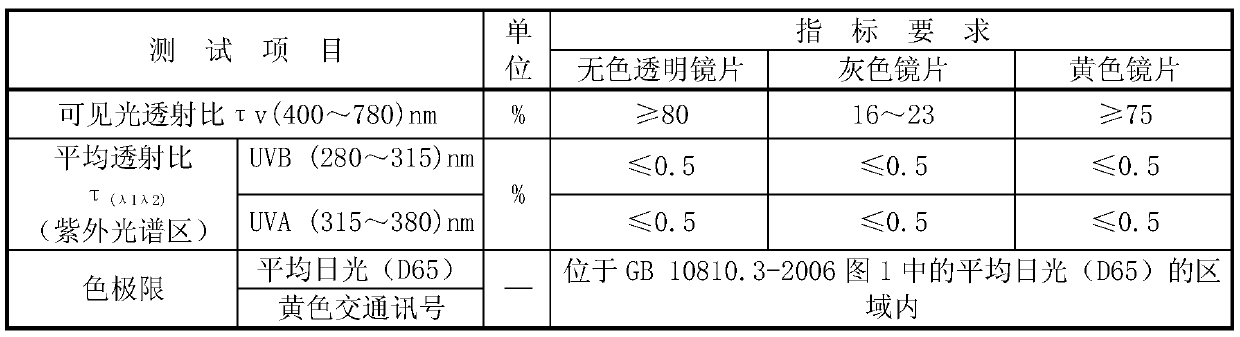

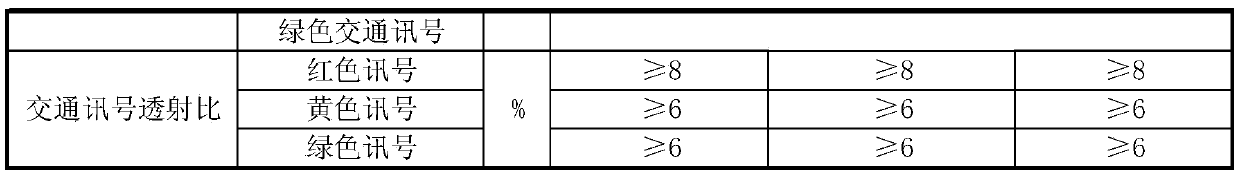

[0080] Light transmission performance

[0081] According to the provisions of GB 10810.3-2006, the visible light transmittance, average transmittance (ultraviolet spectrum region), color limit, and traffic signal transmittance of the lens shall comply with the provisions in Table 1. (Among them, the gray lens is obtained by adding a gray dye to the lens material, and the yellow lens is obtained by adding a yellow dye to the lens material)

[0082] Table 1 Lens light transmission performance

[0083]

[0084]

[0085] Anti-sun radiation

[0086] According to the provisions of ISO 12311, the relative change between the light transmission τV' of color...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com