Superhydrophilic-underwater superoleophobic modified separation membrane, its preparation method and application

An underwater super-oleophobic and super-hydrophilic technology, applied in oil-water separation membranes and oil-water separation applications, can solve the problem of water flux decline and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] One aspect of the embodiments of the present invention provides a method for preparing a superhydrophilic-underwater superoleophobic modified separation membrane, which includes:

[0023] Disperse graphene oxide and one-dimensional single-walled aluminosilicate nanotubes in deionized water to form a mixed dispersion;

[0024] The graphene oxide and one-dimensional single-wall aluminosilicate nanotubes in the mixed dispersion liquid are deposited on the surface of the polymer microfiltration membrane, and after drying, a modified separation membrane of superhydrophilic-underwater superoleophobic is obtained.

[0025] In some embodiments, the preparation method includes: adding graphene oxide and one-dimensional single-walled aluminosilicate nanotubes into deionized water, and then ultrasonicating for 20 to 60 minutes to form the mixed dispersion;

[0026] In some embodiments, the preparation method includes: using vacuum filtration to deposit graphene oxide and one-dimen...

Embodiment 1

[0043] Embodiment 1 A kind of preparation method of superhydrophilic-underwater superoleophobic modified nylon membrane can be carried out according to the following steps:

[0044] (1) Add 0.1 mg of graphene oxide and 1.0 mg of one-dimensional single-walled aluminosilicate nanotubes into 30 mL of deionized water, and ultrasonically disperse for 30 minutes;

[0045] (2) By vacuum filtration, the mixed dispersion obtained in step (1) is deposited on the surface of the nylon microfiltration membrane by suction filtration, and dried to obtain a superhydrophilic-underwater superoleophobic modified nylon membrane.

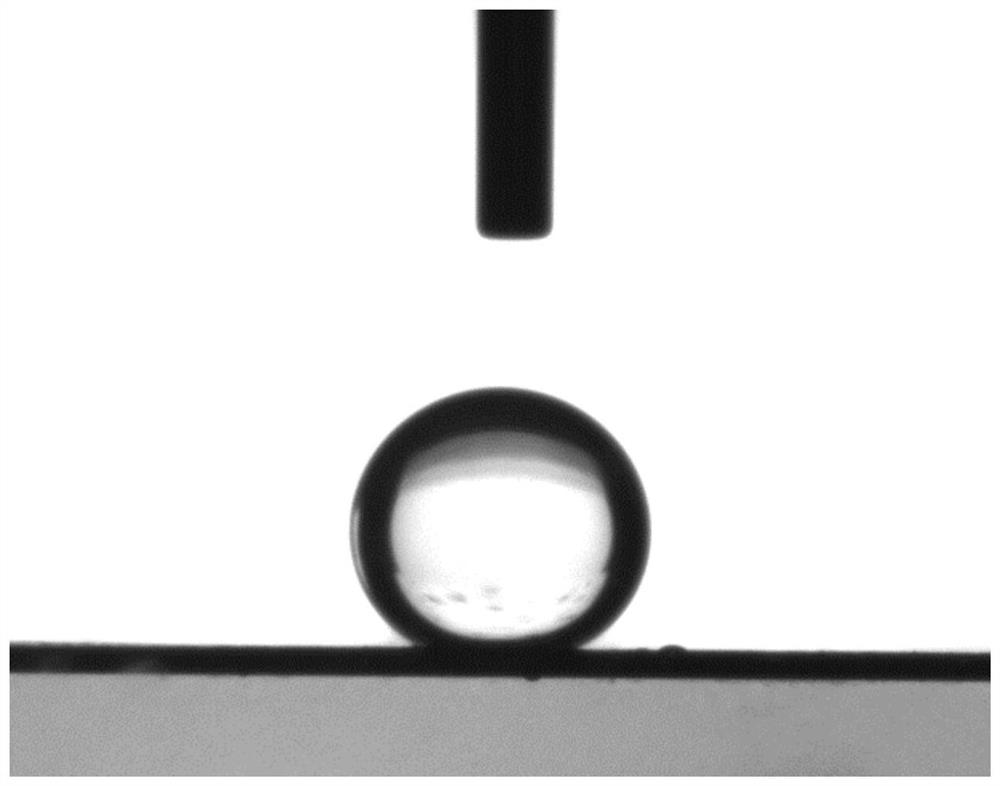

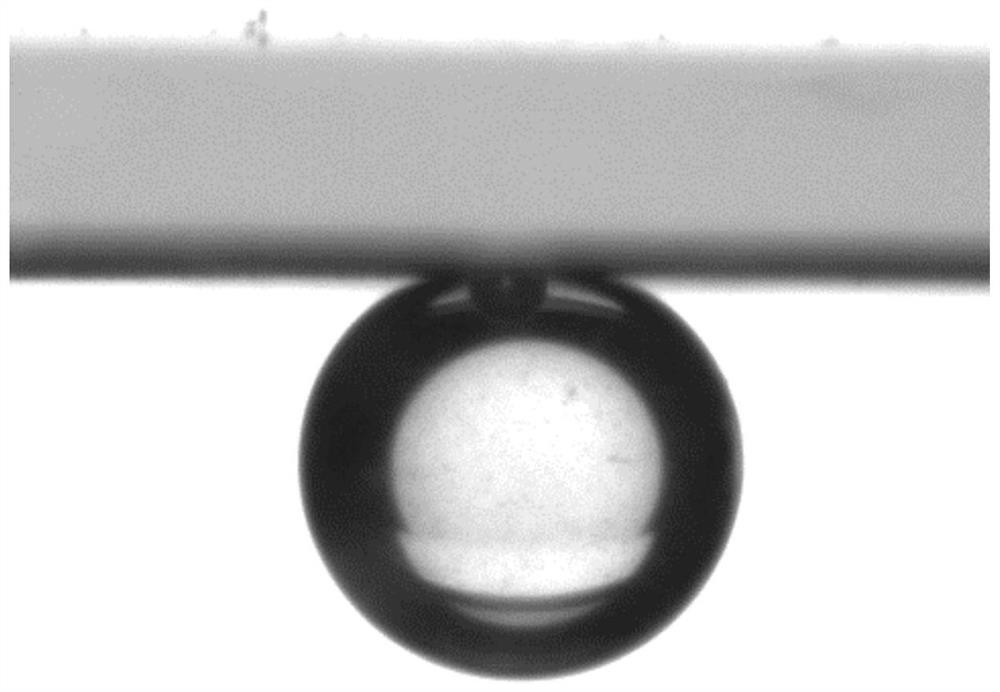

[0046] The water contact angle of the modified nylon membrane that present embodiment obtains is 0 ° (see figure 1 ), it was placed under water to measure the contact angle of this film with 1 microliter of methylene chloride to be about 153° (see figure 2 ).

[0047] use as Figure 5 The experimental device shown is used for the oil-water separation test of the mod...

Embodiment 2

[0049] Embodiment 2 A kind of preparation method of superhydrophilic-underwater superoleophobic modified mixed cellulose membrane can be carried out according to the following steps:

[0050] (1) Add 0.1 mg of graphene oxide and 2 mg of one-dimensional single-walled aluminosilicate nanotubes into 30 mL of deionized water, and ultrasonically disperse for 40 minutes;

[0051] (2) Then, by vacuum filtration, the mixed dispersion liquid obtained in step (1) is deposited onto the surface of the mixed cellulose microfiltration membrane by suction filtration, and dried to obtain a super-hydrophilic-underwater super-oleophobic modification Mixed cellulose membrane.

[0052] The water contact angle of the modified mixed cellulose that the present embodiment obtains is 0 °, and it is placed under water to measure this film and the contact angle of 1 microliter of toluene is about 153 ° (see image 3 ).

[0053] use as Figure 5 The experimental device shown is used for the oil-water se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| oil-water separation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com