Room-temperature solidified super-oleophobic polyurethane coating

A polyurethane coating, room temperature curing technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of uneconomical, large energy consumption, and environmental protection, and achieve the effect of simple and easy method and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

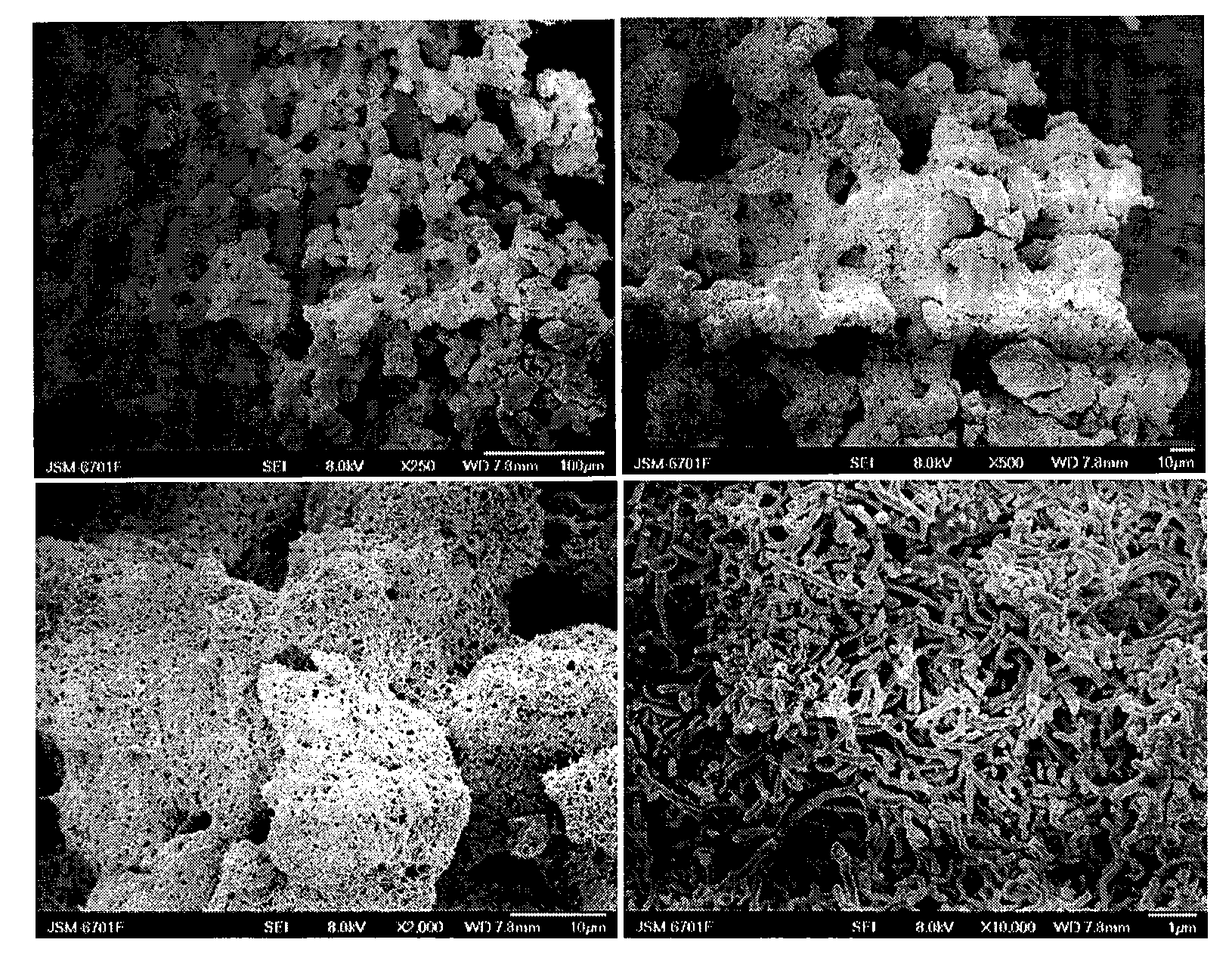

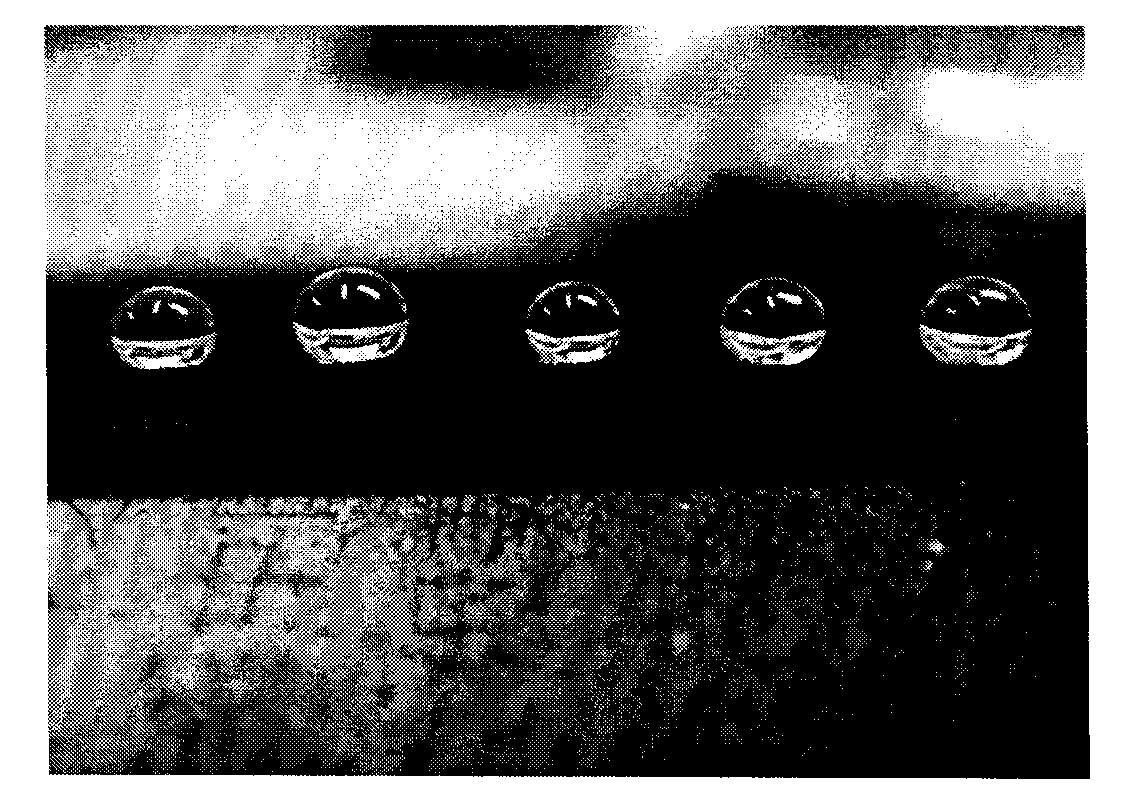

Image

Examples

Embodiment 1

[0022] Carbon nanotube perfluoroalkylation treatment, the treatment steps are: 1) immerse 3g carbon nanotubes with a diameter of 40-60nm in 100mL of sulfuric acid / nitric acid solution with a volume ratio of 3 / 1, and stir at room temperature for 24 hours for acidification After treatment, the treated carbon nanotubes are washed with water to neutrality after suction filtration; (2) 1 g of acidified carbon nanotubes are placed in 50 mL of SOCl 2 The medium was heated under reflux for 24 hours to carry out acylation treatment, and after suction filtration, the excess was washed with anhydrous tetrahydrofuran, and then vacuum-dried for 3 hours; (3) 0.5 g of acylated carbon nanotubes were placed in 20 g of perfluorooctyl methanol solution , stirring and heating for 24 hours to carry out an esterification reaction, and the obtained carbon nanotubes are washed with methylhydrofuran to remove unreacted perfluorooctyl methanol and then dried to obtain perfluoroalkylated carbon nanotubes...

Embodiment 2

[0027] Carbon nanotube perfluoroalkylation treatment, the treatment steps are: 1) immerse 3g carbon nanotubes with a diameter of 20-40nm in 100mL of sulfuric acid / nitric acid solution with a volume ratio of 3 / 1, and stir at room temperature for 24 hours for acidification After treatment, the treated carbon nanotubes are washed with water to neutrality after suction filtration; (2) 1 g of acidified carbon nanotubes are placed in 50 mL of SOCl 2 The medium was heated under reflux for 24 hours to carry out acylation treatment, and after suction filtration, the excess was washed with anhydrous tetrahydrofuran, and then vacuum-dried for 3 hours; (3) 0.5 g of acylated carbon nanotubes were placed in 20 g of perfluorooctyl methanol solution , stirring and heating for 24 hours to carry out the esterification reaction, the obtained carbon nanotubes are washed with tetrahydrofuran to remove unreacted perfluorooctyl methanol, and then dried to obtain perfluoroalkylated carbon nanotubes fo...

Embodiment 3

[0031] Carbon nanotube perfluoroalkylation treatment, the treatment steps are: 1) immerse 3g carbon nanotubes with a diameter of 40-60nm in 100mL of sulfuric acid / nitric acid solution with a volume ratio of 3 / 1, and stir at room temperature for 24 hours for acidification After treatment, the treated carbon nanotubes are washed with water to neutrality after suction filtration; (2) 1 g of acidified carbon nanotubes are placed in 50 mL of SOCl 2 The medium was heated under reflux for 24 hours to carry out acylation treatment, and after suction filtration, the excess was washed with anhydrous tetrahydrofuran, and then vacuum-dried for 3 hours; (3) 0.5 g of acylated carbon nanotubes were placed in 20 g of perfluorooctyl methanol solution , stirring and heating for 24 hours to carry out an esterification reaction, and the obtained carbon nanotubes are washed with tetrahydrofuran to remove unreacted perfluorooctyl methanol and then dried to obtain perfluorodecylated carbon nanotubes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com