A kind of transparent superhydrophobic coating material and the method for preparing transparent superhydrophobic coating thereof

A super-hydrophobic coating and transparent technology, applied in coatings, polyurea/polyurethane coatings, devices for coating liquids on surfaces, etc., can solve the problem that super-hydrophobic coatings cannot obtain transparency, durability and erasability at the same time And repeated coating, temperature and pH stability, droplet impact resistance, versatility and other issues, to achieve the effect of simple and convenient preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

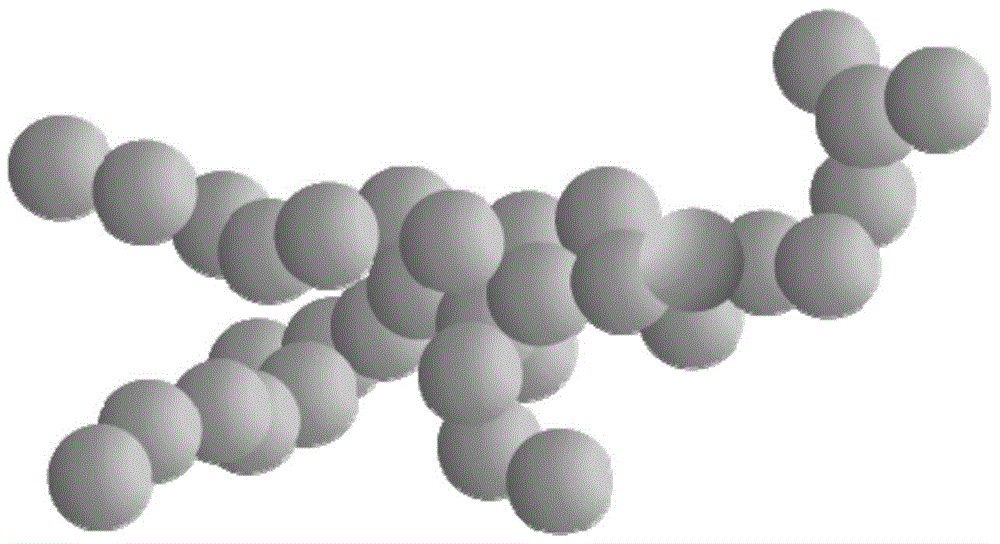

[0070] 1. Weigh 0.2g fumed silica nanoparticles (specific surface area is 300m 2 / g) and 20g of absolute ethanol, the fumed silica nanoparticles are dispersed in ethanol by magnetic stirring and an ultrasonic disperser to obtain a uniform and stable dispersion.

[0071] 2. Cut out a textile cloth of a certain size, and soak the textile cloth with the dispersion liquid in step 1. Wipe the glass surface with the woven cloth.

[0072] 3. After the ethanol is completely volatilized, put the wiped glass and 200 μL of 1H,1H,2H,2H-perfluorodecyltriethoxysilane into a closed desiccator and heat it. Incubate at 180°C for 3h. The glass is then taken out of the desiccator to obtain a superhydrophobic coating.

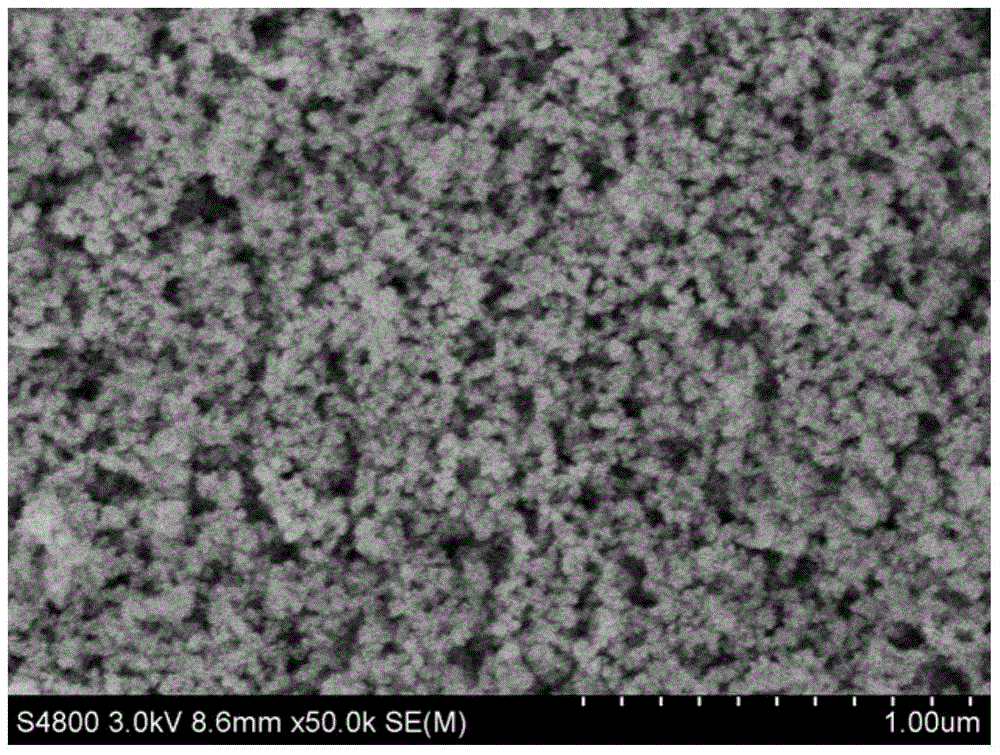

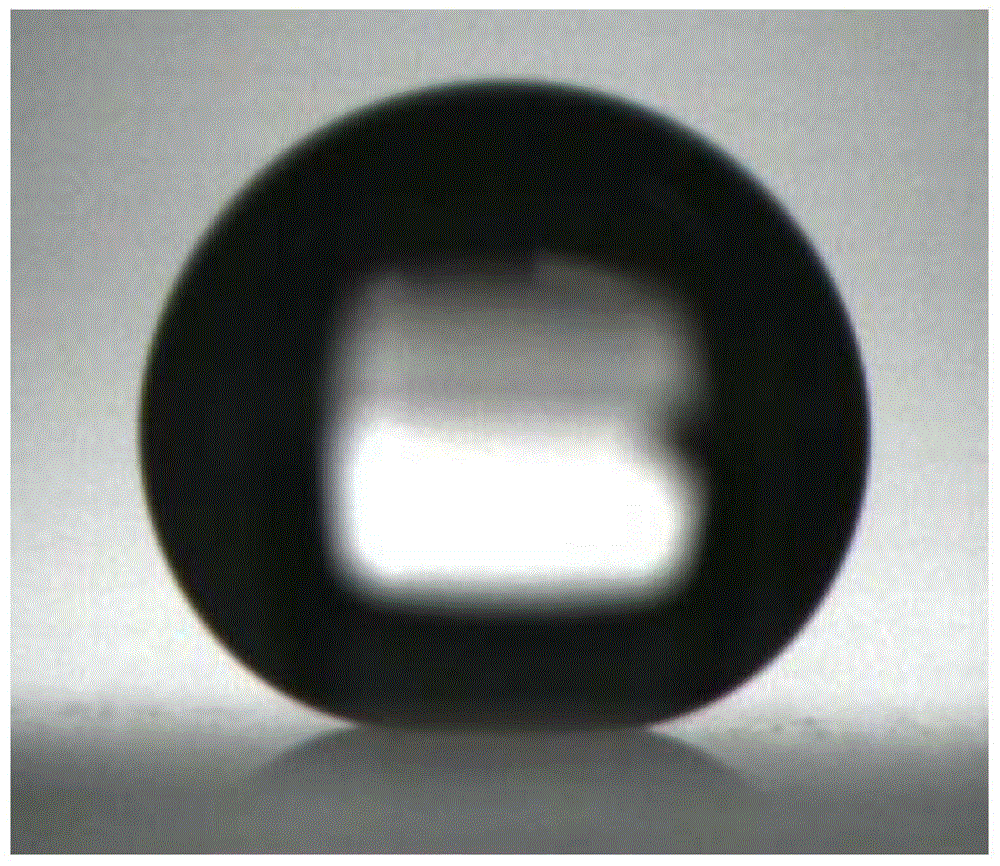

[0073] SEM observation showed that the coating had a porous microstructure ( figure 2 ). The contact angle of the superhydrophobic coating to the droplet is measured by a contact angle tester to be 165.7 ° ( image 3 ), the roll angle is 1°. Figure 4 It shows that the sup...

Embodiment 2

[0075] 1. Weigh 0.2g fumed silica nanoparticles (specific surface area is 100m 2 / g) and 20g of water, the fumed silica nanoparticles are dispersed in water by magnetic stirring and ultrasonic disperser to prepare a uniform and stable dispersion.

[0076] 2. Cut out a non-woven fabric of a certain size, soak the non-woven fabric with the dispersion in step 1, and then wipe it on the glass surface.

[0077]3. After the water is completely evaporated, put the coated glass and 200 μL of 1H,1H,2H,2H-perfluorodecyltriethoxysilane into a closed desiccator and heat it. Incubate at 100°C for 3h. The glass is then removed from the desiccator to produce a superhydrophobic coating.

[0078] The superhydrophobic coating has a contact angle of 162.1° and a rolling angle of 2°. Other properties such as transparency, self-cleaning ability, etc. are the same as in Example 1.

Embodiment 3

[0080] 1. Weigh 0.1g fumed silica nanoparticles (specific surface area is 600m 2 / g) and 50g of absolute ethanol, the fumed silica nanoparticles were dispersed in ethanol by magnetic stirring and ultrasonic disperser to prepare a uniform and stable dispersion.

[0081] 2. Cut out a textile cloth of a certain size, soak the textile cloth with the dispersion in step 1, and then wipe the glass surface.

[0082] 3. After the ethanol is completely volatilized, put the coated glass and 200 μL of 1H,1H,2H,2H-perfluorodecyltriethoxysilane into a closed desiccator and heat it. Incubate at 160°C for 3h. The glass is then removed from the desiccator to produce a superhydrophobic coating.

[0083] The superhydrophobic coating has a contact angle of 168.5° and a rolling angle of 2°. Transparency is better than Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com