Fat emulsifier for feed use, preparation method and application thereof

A technology of fat emulsifier and feed, which is applied in the field of livestock and poultry feeding, can solve the problems of poor stability of oil-emulsifier-water complex, restrict the popularization and use of feed emulsifier, and not participate in the process of fat digestion and absorption, and achieve improved Sustained emulsification ability, enhanced cellular immunity, and reduced breeding costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

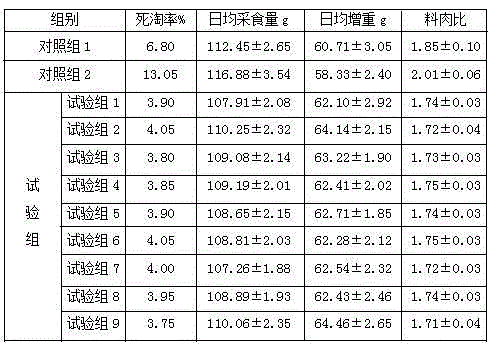

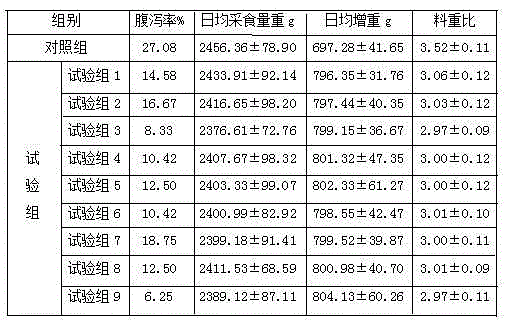

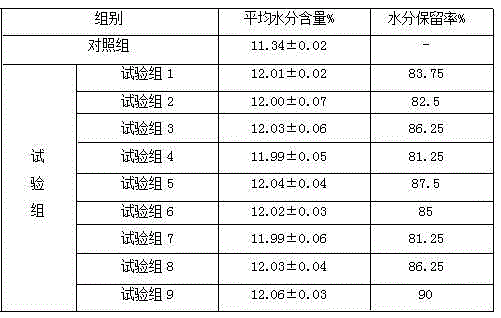

Examples

Embodiment 1

[0033] Embodiment 1, a feed fat emulsifier, the composition by weight is as follows: 200 parts of concentrated phospholipids, 20 parts of sucrose esters, 10 parts of monoglycerides, 10 parts of taurine, 50 parts of yeast cell wall polysaccharides, 30 parts of trehalose 100 parts of betaine anhydrous, 20 parts of lipase, 560 parts of cornstarch.

Embodiment 2

[0034] Embodiment 2, a kind of feed fat emulsifier, is composed as follows by weight: 250 parts of powdered phospholipids, 30 parts of sucrose esters, 10 parts of monoglycerides, 10 parts of taurine, 75 parts of gum arabic, 25 parts of trehalose, 150 parts of betaine monohydrate, 20 parts of lipase, 430 parts of white carbon black.

Embodiment 3

[0035] Embodiment 3, a feed fat emulsifier, the composition by weight is as follows: 250 parts of expanded lecithin, 20 parts of sucrose ester, 20 parts of monoglyceride, 15 parts of taurine, 90 parts of soluble soybean polysaccharide, 40 parts of trehalose , 100 parts of betaine hydrochloride, 25 parts of lipase, 450 parts of stone powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com