Preparation method and application of novel polymeric surfactant

A surfactant and polymer technology, applied in the field of preparation of new polymer surfactants, can solve problems such as poor migration speed, chromatographic separation, and weakened synergistic effect of oil displacement agents, and achieve good oil washing ability and wide application Prospect, effect of reversible aggregation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

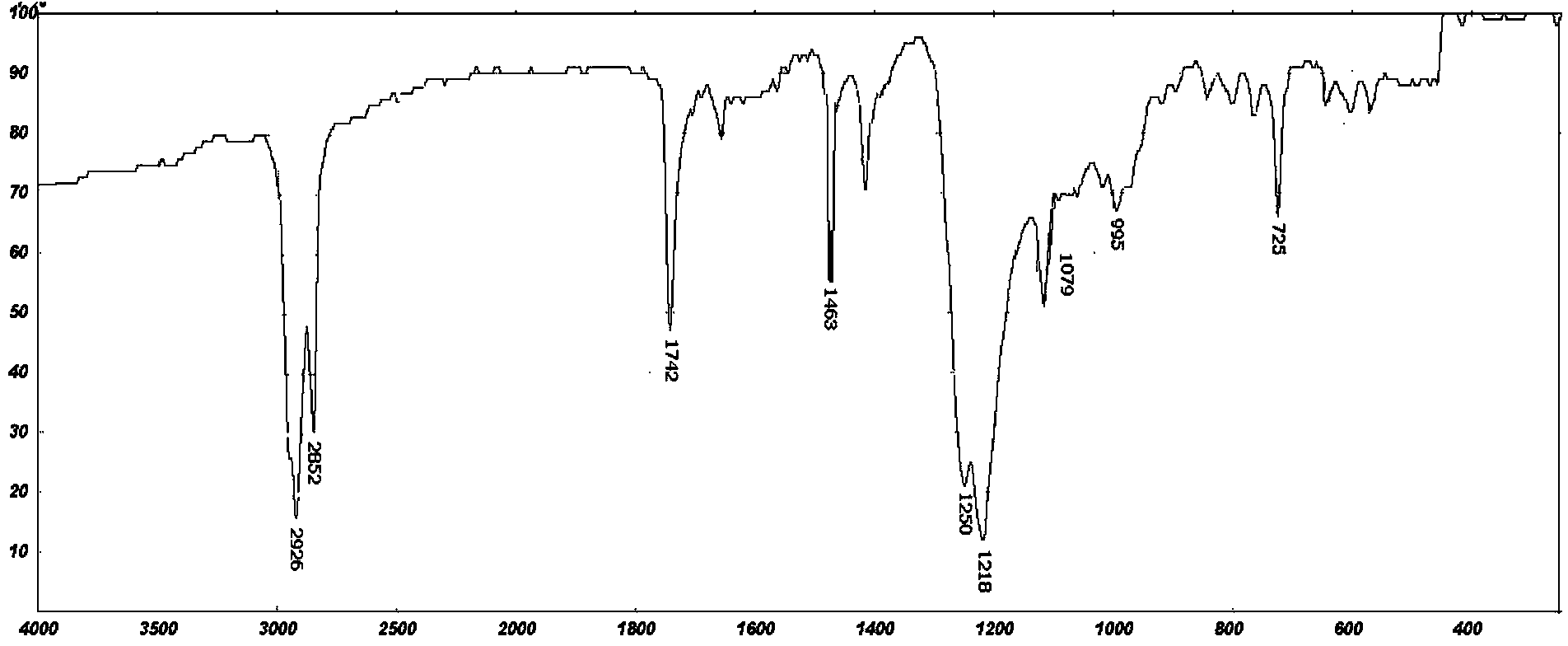

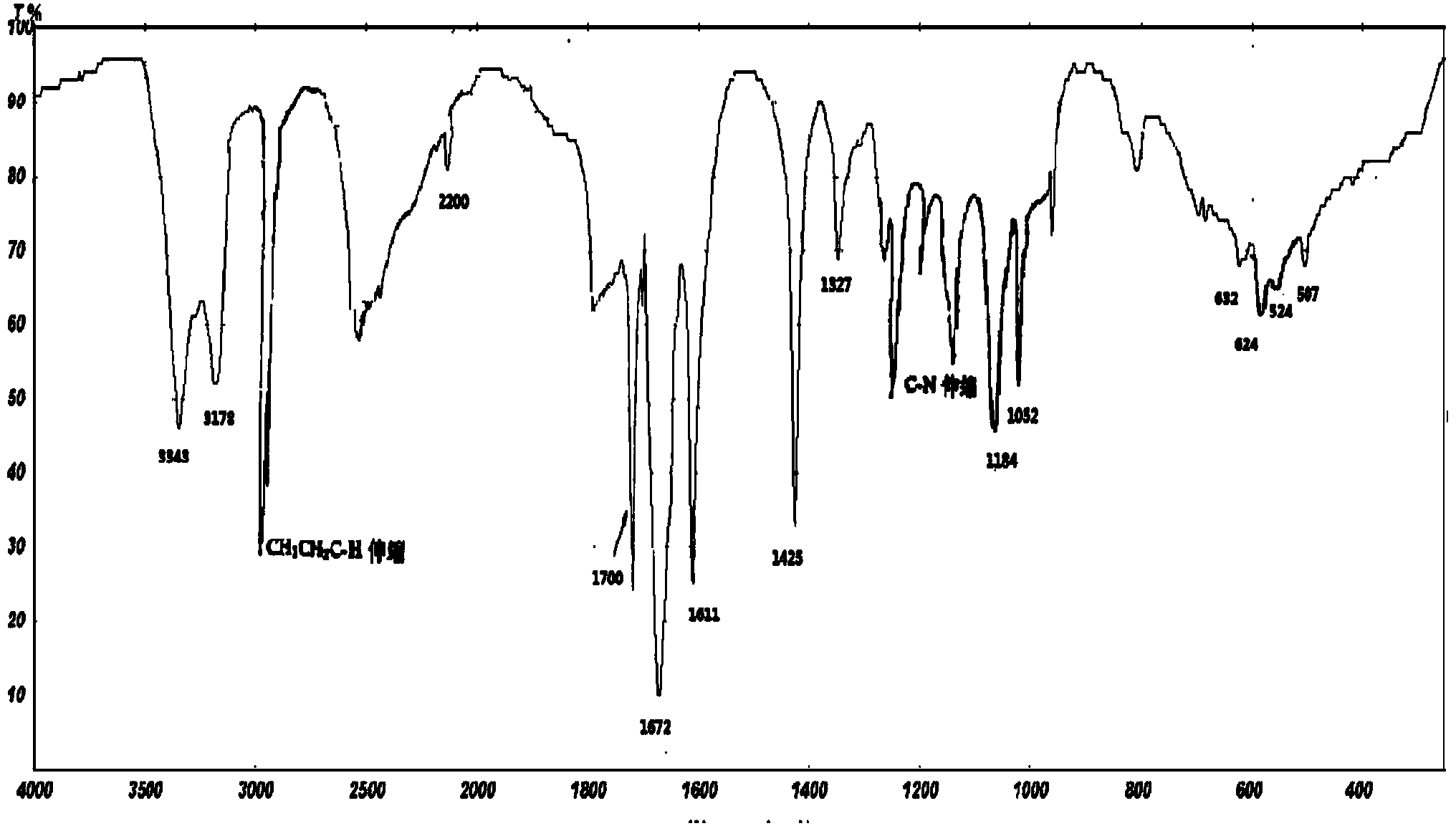

Image

Examples

preparation example Construction

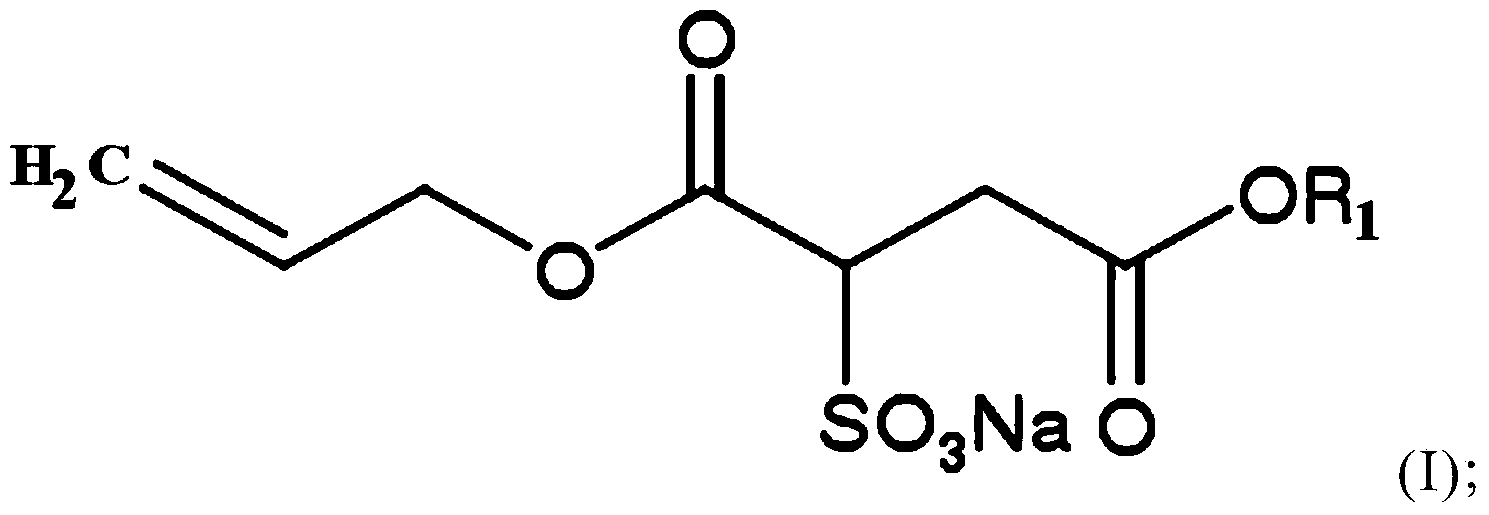

[0041] The invention discloses a preparation method of an active monomer, comprising the following steps:

[0042] Maleic anhydride and C8~C20 fatty alcohol undergo esterification reaction to obtain the first intermediate product;

[0043] reacting the first intermediate product with an allyl haloalkene to obtain a second intermediate product;

[0044] The second intermediate product is reacted with sodium bisulfite to obtain the active monomer represented by formula (I).

[0045] In the present invention, the concrete synthetic route of preparing active monomer is as follows:

[0046]

[0047] Firstly, maleic anhydride and C8-C20 fatty alcohol undergo esterification reaction to obtain the first intermediate product. The C8-C20 fatty alcohol is preferably n-octanol, n-dodecyl alcohol, n-tetradecyl alcohol or n-hexadecanol. The mass ratio of the maleic anhydride to the fatty alcohol is preferably 1:1. The temperature of the reaction is preferably 80-100° C., and the time...

Embodiment 1

[0076] Add 20g of maleic anhydride, 20g of n-octanol, and 0.2g of anhydrous sodium acetate into a four-necked flask in sequence, stir and heat up to 90°C within 10 minutes, and react for 3 hours to obtain the first intermediate product;

[0077] Add the first intermediate product, anhydrous sodium carbonate, into a four-necked flask in turn, react at 75°C for 25min, then add triethylamine, cool down to 55°C, and dropwise add 50 parts of chloropropene and 50 parts of A mixed solution of acetone was prepared, and the temperature of the water bath was kept at 54°C, and the mixture was stirred and refluxed for 6 hours. The reaction mixture was filtered to remove solid impurities, and the filtrate was rotary evaporated to remove excess chloropropene and solvent acetone, then washed with water three times, separated, and the upper oily liquid was added to anhydrous CaCl 2 Dry, let stand overnight, filter to remove CaCl 2 , to obtain the second intermediate product;

[0078] Add th...

Embodiment 2

[0082] Add 20g of maleic anhydride, 20g of n-dodecyl alcohol, and 0.2g of anhydrous sodium acetate into a four-neck flask in sequence, stir and heat up to 90°C within 10 minutes, and react for 3 hours to obtain the first intermediate product;

[0083] Add the first intermediate product, anhydrous sodium carbonate, into the four-necked flask in turn, react at 78°C for 27min, then add triethylamine, cool down to 55°C, add 50 parts of chloropropene and 50 parts of A mixed solution of acetone was kept at a water bath temperature of 60°C, and the mixture was stirred and refluxed for 5.5 hours. The reaction mixture was filtered to remove solid impurities, and the filtrate was rotary evaporated to remove excess chloropropene and solvent acetone, then washed with water three times, separated, and the upper oily liquid was added to anhydrous CaCl 2 Dry, let stand overnight, filter to remove CaCl 2 , to obtain the second intermediate product;

[0084] Add the second intermediate produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com