Heavy oil modification and viscosity reduction rare earth catalyst and use method thereof

A technology for modifying viscosity and reducing catalysts, which is applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., and can solve catalyst poisoning, non-catalytic function, and production costs Increase and other problems, to achieve the effect of low cost, convenient preparation, and reduce the viscosity of heavy oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

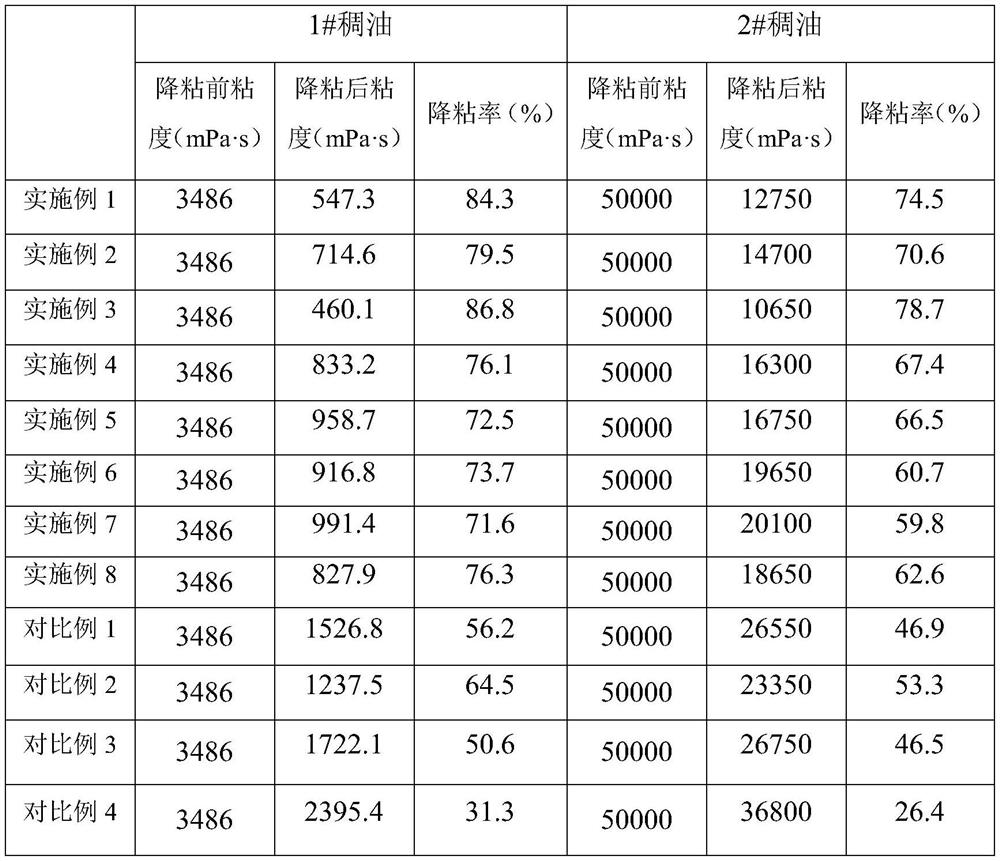

Examples

Embodiment 1

[0027] Put 120g of heavy oil sample into the autoclave, add 45mL of water, 0.25g of cerium nitrate, and 4.7g of tetrahydronaphthalene respectively. After stirring evenly, close the lid of the kettle, control the reaction temperature to 240°C, and the reaction time to 24h. After the reaction was completed, the oil sample was taken out to measure the viscosity change of the heavy oil.

Embodiment 2

[0029] Put 100g of heavy oil sample into the autoclave, add 30mL of water, 1.0g of lanthanum chloride, 1.0g of dihydroanthracene respectively, after stirring evenly, close the lid of the kettle, control the reaction temperature to be 180°C, and the reaction time to be 30h, After the reaction was completed, the oil sample was taken out to measure the viscosity change of the heavy oil.

Embodiment 3

[0031] Load 100g of heavy oil samples into the autoclave, add 60mL of water, 0.5g of cerium oxalate, 2.5g of lanthanum chloride, and 5.0g of formic acid, stir evenly, close the lid, and control the reaction temperature to be 200° C. The reaction time After the reaction was completed, the oil sample was taken out to measure the viscosity change of the heavy oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com