Preparation of water-soluble salt-resistant dispersing drag reducer for heavy oil exploitation

A water-soluble, drag-reducing agent technology, applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as failure to meet the requirements of heavy oil exploitation, reduce adsorption force, reduce viscosity of heavy oil, and improve The effect of technological progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

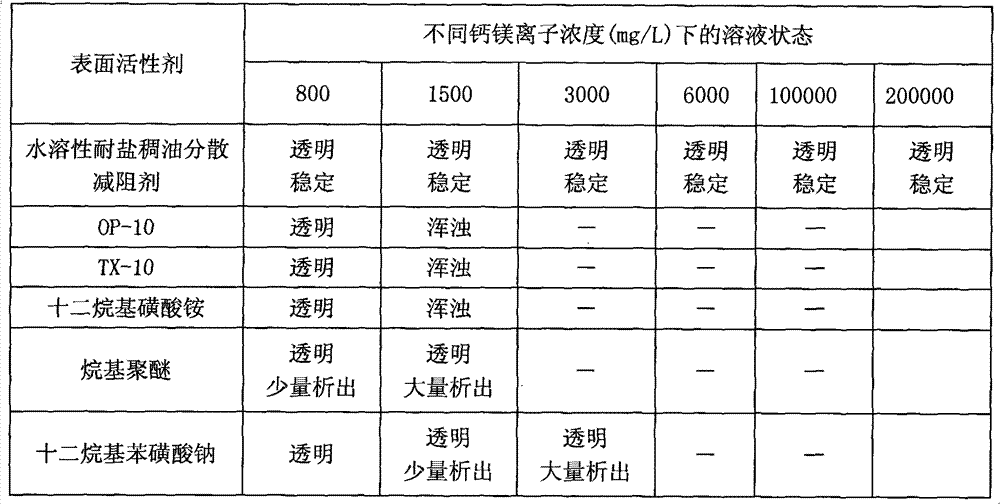

[0033] The product is composed of water-soluble salt-tolerant surfactant agent A and polymer active polymer agent B; it is prepared in parts by weight; agent A needs to be formulated with formation water, and agent B needs to be formulated with clear water, and used after mixing.

[0034] Agent A: 163 parts of nonylphenol, 2 parts of potassium hydroxide, 87 parts of allyl glycidyl ether, 30.5 parts of sulfamic acid, 13 parts of urea, 0.5 part of thiourea, 4 parts of ammonia water, 50 parts of trichlorethylene, 650 parts of pure water;

[0035] In addition, 170 parts of nonylphenol, 3 parts of potassium hydroxide, 90 parts of allyl glycidyl ether, 32 parts of sulfamic acid, 14 parts of urea, 0.7 parts of thiourea, 5 parts of ammonia water, 55 parts of trichlorethylene, pure water 670 components;

[0036] Preparation:

[0037] ① Add nonylphenol and potassium hydroxide to the reaction kettle, replace with nitrogen 4 times, stir and raise the temperature to 120°C, after constant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com