Neutralization-preventive high-early-strength cement composition

A technology for early-strength cement and composition, applied in solid waste management, climate sustainability, sustainable waste treatment, etc., can solve the problems of poor strength performance and low strength performance, and achieve excellent short-term strength performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

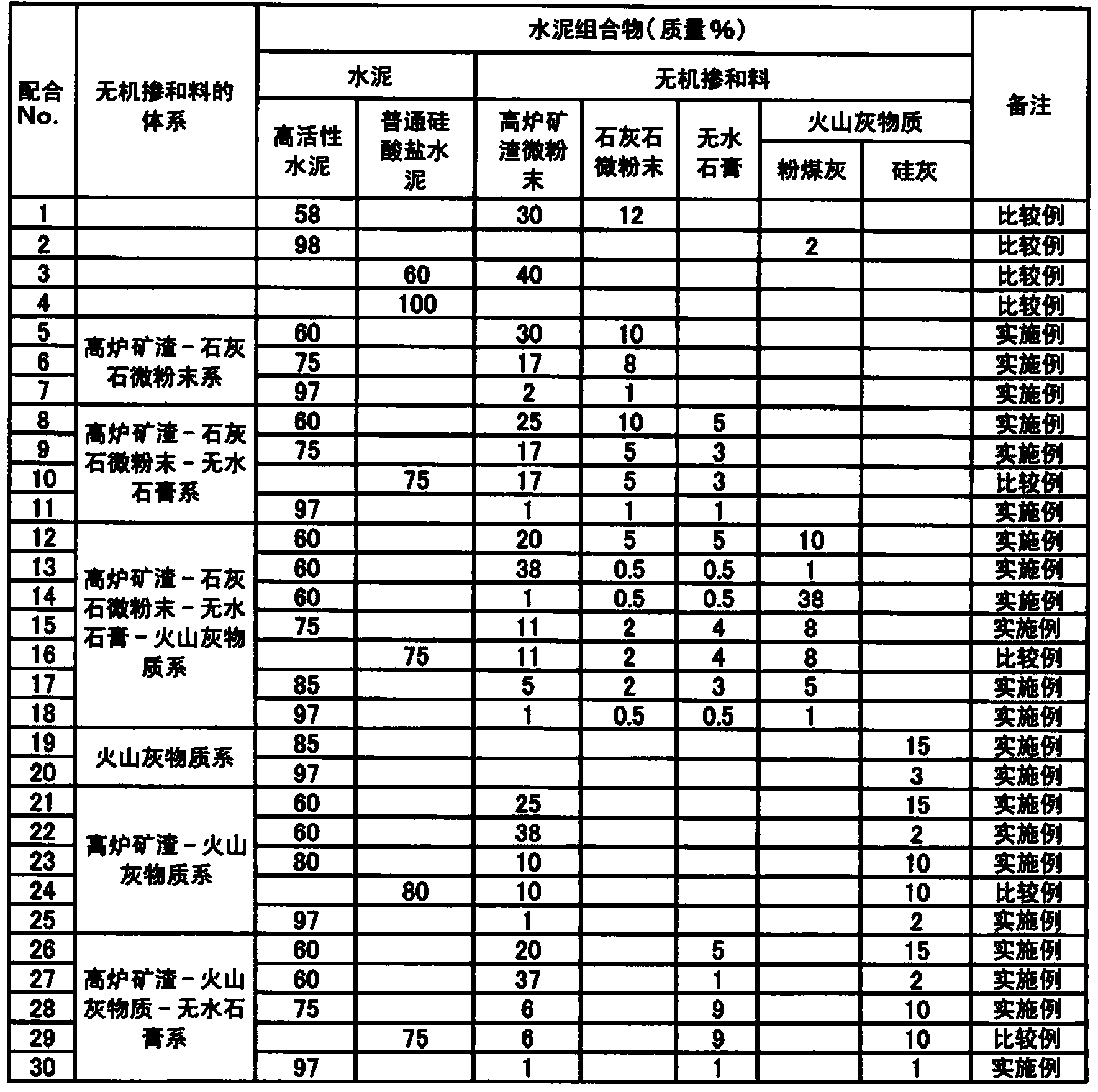

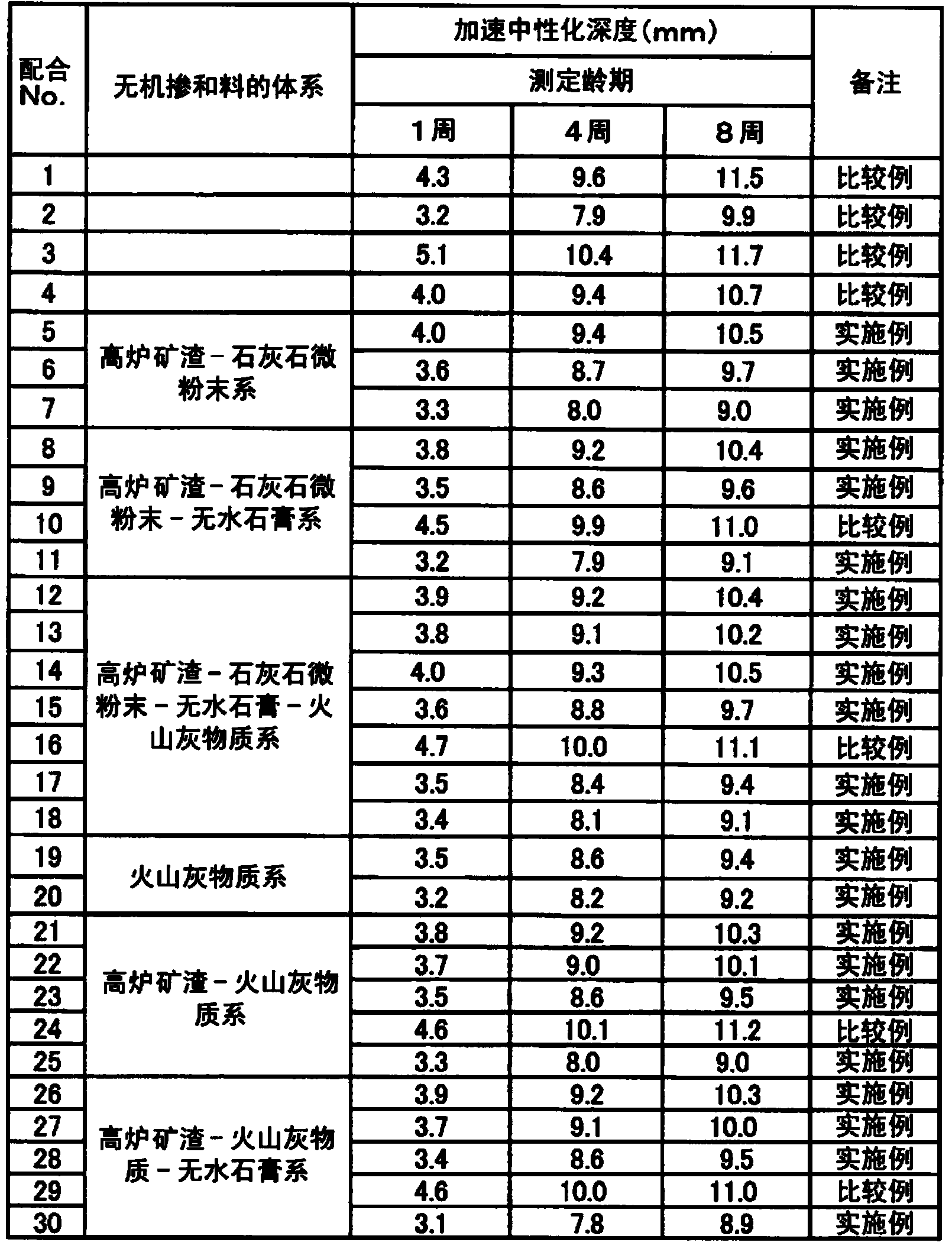

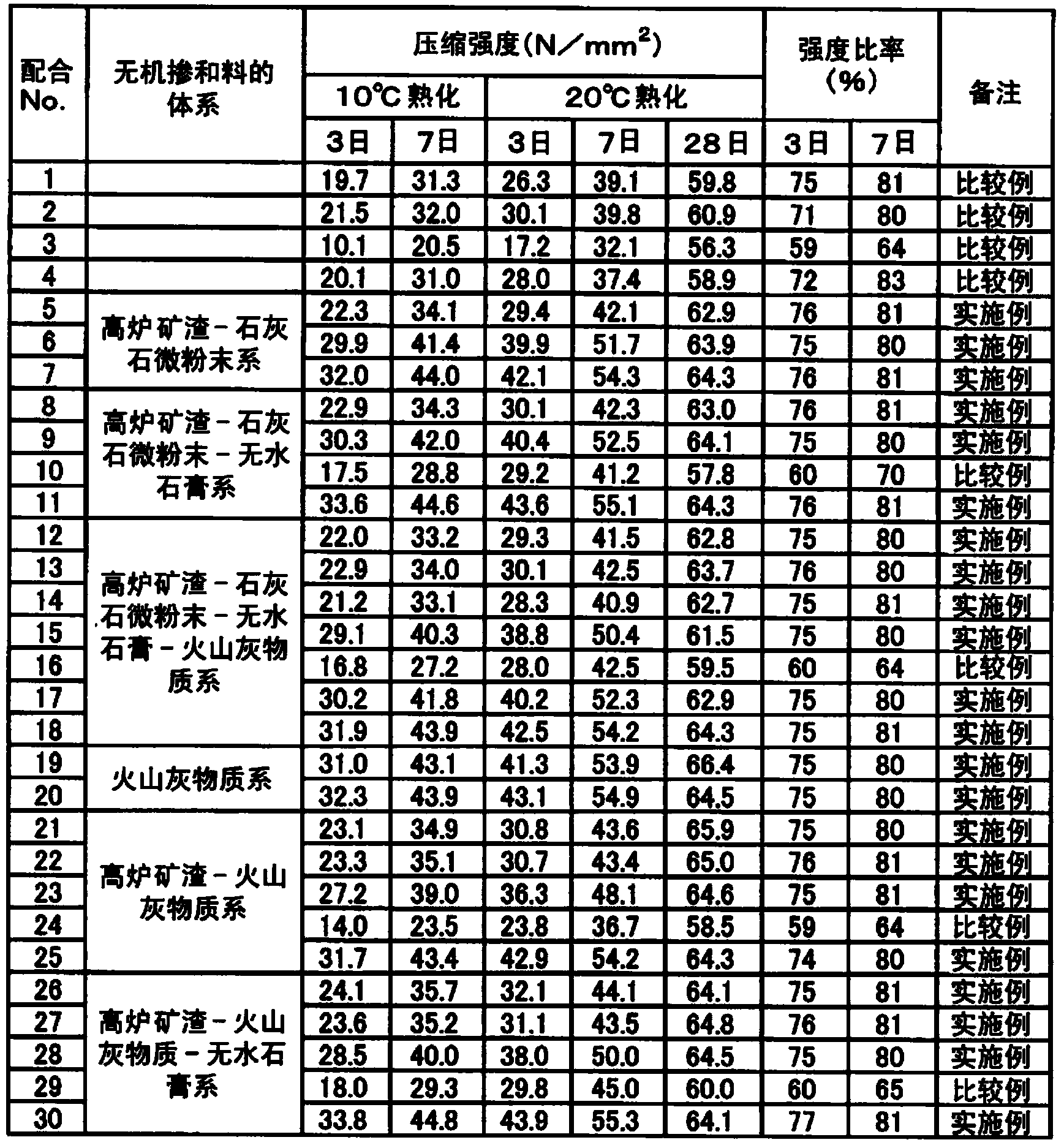

[0079] Hereinafter, the neutralization suppression type early-strength cement composition of this invention is demonstrated in more detail.

[0080] Neutralization inhibition type early-strength cement composition of the present invention is described above by " high activity cement " and inorganic admixture (in blast furnace slag, anhydrous gypsum, limestone fine powder, volcanic ash material) that the inventor etc. develop in the past more than one) formed. First, these respective materials will be described.

[0081] [constitution material]

[0082] A. High activity cement

[0083] The highly active cement used in the present invention is the highly active cement developed by the present inventors before the present invention, and is obtained by adding gypsum to the conventionally developed highly active cement clinker. The short-term strength performance and medium-to-long-term performance are both good, and it is effective for neutralization suppression.

[0084] [Hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bryan value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com