Supramolecular self-assembly clean fracturing fluid and preparation method thereof

A supramolecular self-assembly and cleaning fracturing fluid technology, applied in chemical instruments and methods, drilling compositions, bulk chemical production, etc., can solve problems such as formation permeability damage and impact on fracturing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

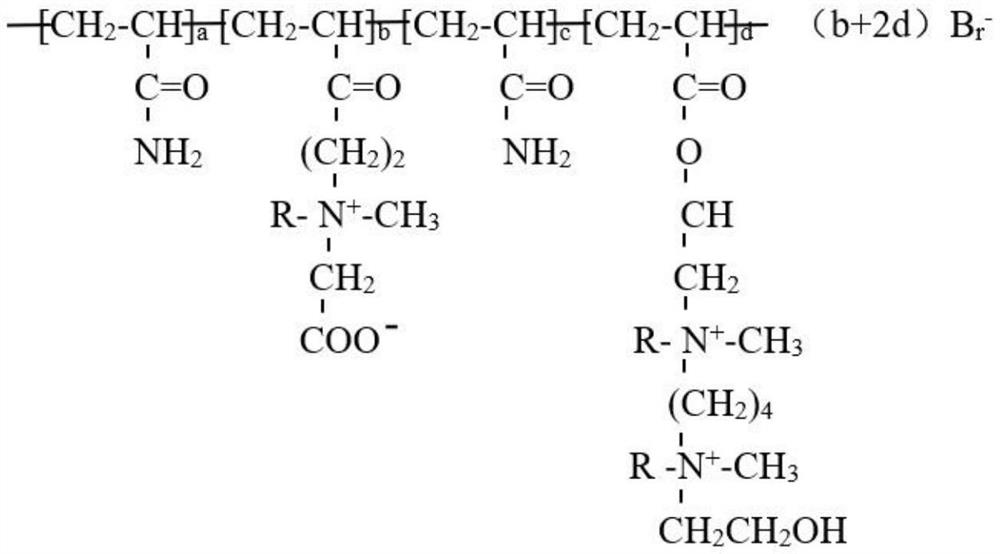

Method used

Image

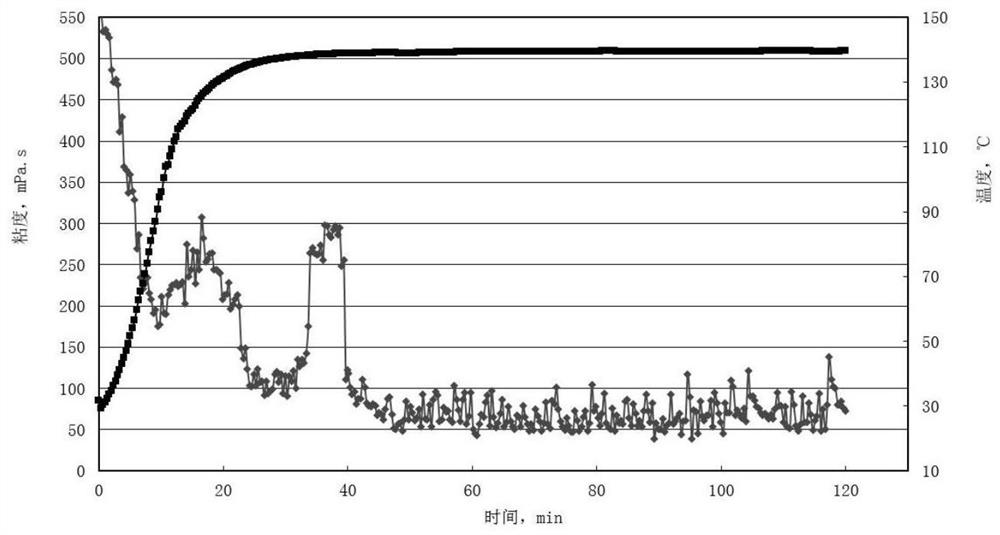

Examples

Embodiment 1

[0038] step 1)

[0039] In the three-necked flask with adjustable reflux fractionation column, add 87g (1mol) of MMA and 96g (0.4mol) of N-methyl, N-hydroxyethyl dodecylamine, then add 8g of p-toluenesulfonic acid and 0.2 g phenothiazine. The reaction was stirred and heated to reflux, the product methanol was separated from the top of the column, and MMA was refluxed into the reaction bottle. React for 3.5 hours, rectify and separate excess MMA, and then distill under reduced pressure to obtain product intermediate 1-1, N-fatty amine, N-methyl, N-ethyl acrylate

[0040] Step 2)

[0041] Add 28.3g of intermediate 1-1 (C12, 0.1mol) to the flask, add 75mL of isopropanol, add 40g (0.1mol) of 30% sodium chloroacetate aqueous solution dropwise in a water bath at 45°C, and control the reaction temperature not higher than 60 °C, after the addition is completed, slowly heat in a water bath to raise the temperature to 80-90 °C for 2 hours. After the reaction is completed, cool, filte...

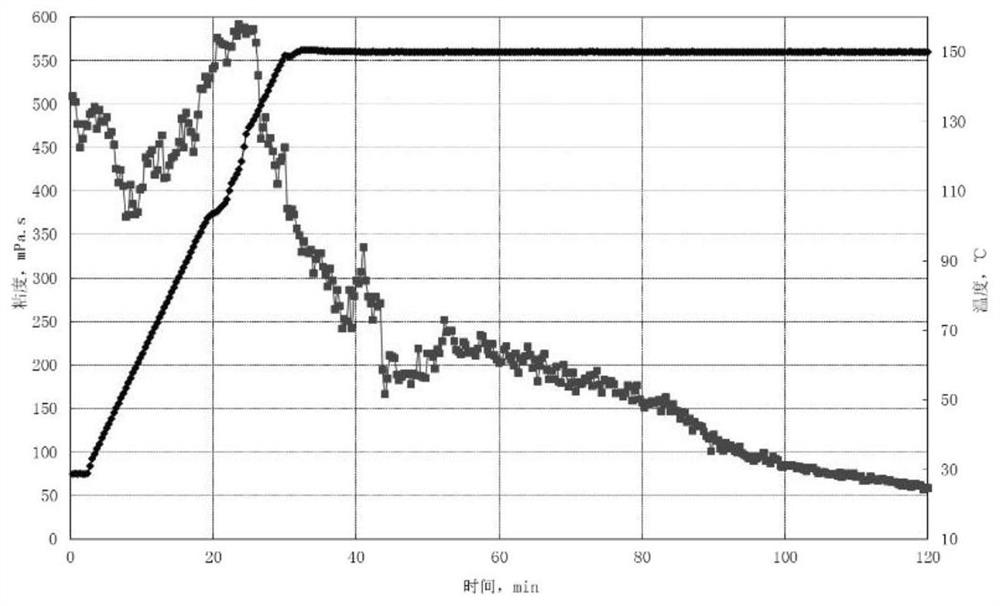

Embodiment 2

[0049] step 1)

[0050] In the three-necked flask with adjustable reflux fractionation column, add 87g (1mol) of MMA and 107g (0.4mol) of N-methyl, N-hydroxyethyl tetradecylamine, then add 8g of p-toluenesulfonic acid and 0.2 gPhenothiazine. The reaction was stirred and heated to reflux, the product methanol was separated from the top of the column, and MMA was refluxed into the reaction bottle. React for 3.5 hours, rectify and separate excess MMA, and then distill under reduced pressure to obtain product intermediate 1-2.

[0051] Step 2)

[0052] Add 31.1g of intermediate (1-2) (C14, 0.1mol) to the flask, add 75mL of isopropanol, add 40g (0.1mol) of 30% sodium chloroacetate aqueous solution dropwise in a water bath at 45°C, and control the reaction temperature not to be high At 60°C, after the addition is completed, slowly heat in a water bath to raise the temperature to 80-90°C for 2 hours. After the reaction is completed, cool, filter out the salt, and evaporate the fil...

Embodiment 3

[0060] Take 9.9g of acrylamide, 5.4g of monomer 1-1, 20.7g of monomer 2-1, 7g of PVP, add 113g of water, stir to dissolve, add 44g of ammonium sulfate, blow nitrogen for 20 minutes under stirring, add 0.2g of V50 in a water bath at 50°C Initiator, polymerization reaction for 6 hours to obtain supramolecular self-assembled polymer emulsion 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com