Preparation method of thickening agent for fracturing fluid with temperature of 200 DEG C or above and the fracturing fluid adopting the thickening agent

A thickening agent and fracturing fluid technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of high friction resistance, poor temperature and salt resistance, secondary damage to the formation, etc., and achieve the residue content. Low, fast dissolving speed, good dispersing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

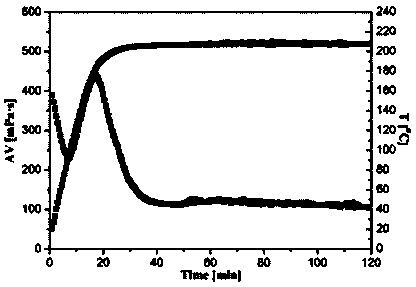

Image

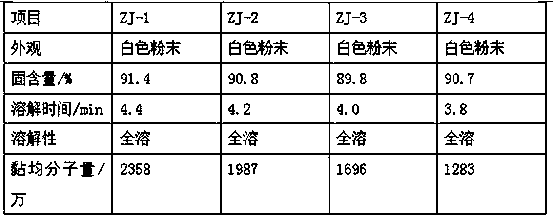

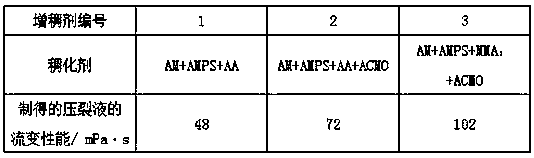

Examples

Embodiment 1

[0030] Embodiment 1, a thickener for fracturing fluid above 200°C and its preparation method, comprising the following steps:

[0031] 1. Preparation of polymer thickener powder:

[0032] (1) Preparation of the solution: mix acrylamide (AM), acryloylmorpholine (ACMO), 2-acrylamido-2-methylpropanesulfonic acid (AMPS), methyl methacrylate (MMA) and dodecane Sodium phenylbenzenesulfonate is fully mixed in distilled water according to the mass ratio of 7:1:1:1:1, and the total concentration of four monomers (AM, ACMO, AMPS and MMA) in the solution is 45% (molar concentration). The solution;

[0033] Join Na 2 CO 3 As a pH regulator, adjust the pH value to 7, and adjust the temperature of the solution to a constant temperature of 15°C in a water bath.

[0034] (2) Polymerization process: Continuously feed 99.999% high-purity nitrogen at a constant temperature of 15°C, and add the composite initiator system composition after 30 minutes;

[0035] The composition consists of N,N-...

Embodiment 2

[0046] Embodiment 2, a thickener for fracturing fluid above 200°C and its preparation method, comprising the following steps:

[0047] 1. Preparation of polymer thickener powder:

[0048] (1) Solution preparation: acrylamide (AM), acryloylmorpholine (ACMO), 2-acrylamido-2-methylpropanesulfonic acid (AMPS), methyl methacrylate (MMA) and dioctylsuccinic acid Sodium is fully mixed in distilled water according to the mass ratio of 12:5:2:1:1, and the total concentration of the four monomers (AM, ACMO, AMPS and MMA) in the solution is 55% (molar concentration);

[0049] Join K 2 CO 3 As a pH regulator, and adjust the pH value to 6.5, the water bath adjusts the temperature of the solution to be constant at 18°C.

[0050] (2) Polymerization process: Continuously feed 99.999% high-purity nitrogen at a constant temperature of 18°C, and add the composite initiator system composition after 60 minutes;

[0051] The composition is composed of N,N,N',N'-tetraethylethylenediamine, sodium...

Embodiment 3

[0058] Embodiment 3, a thickener for fracturing fluid above 200°C and its preparation method, comprising the following steps:

[0059] 1. Preparation of polymer thickener powder:

[0060] (1) Solution preparation: acrylamide (AM), acryloylmorpholine (ACMO), 2-acrylamido-2-methylpropanesulfonic acid (AMPS), methyl methacrylate (MMA) and dodecylbenzene Sodium sulfonate is fully mixed in distilled water according to the mass ratio of 15:3:1:1:1 to prepare a solution of four monomers (AM, ACMO, AMPS and MMA) with a total concentration of 40% (molar concentration) in the solution ;

[0061] NaOH was added as a pH regulator, and the pH value was adjusted to 7.5, and the temperature of the solution was adjusted to a constant temperature of 18° C. in a water bath.

[0062] (2) Polymerization process: Continuously feed 99.999% high-purity nitrogen gas at a constant temperature of 18°C, and add a composite initiator system composition after 60 minutes, which consists of N,N-diethyleth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com