Zwitterionic polymer, preparation method of zwitterionic polymer and application in hydrochloric acid-base fracturing fluid

A technology based on amphoteric ion and hydrochloric acid, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., to achieve the effect of reliable principle, broad market prospect and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

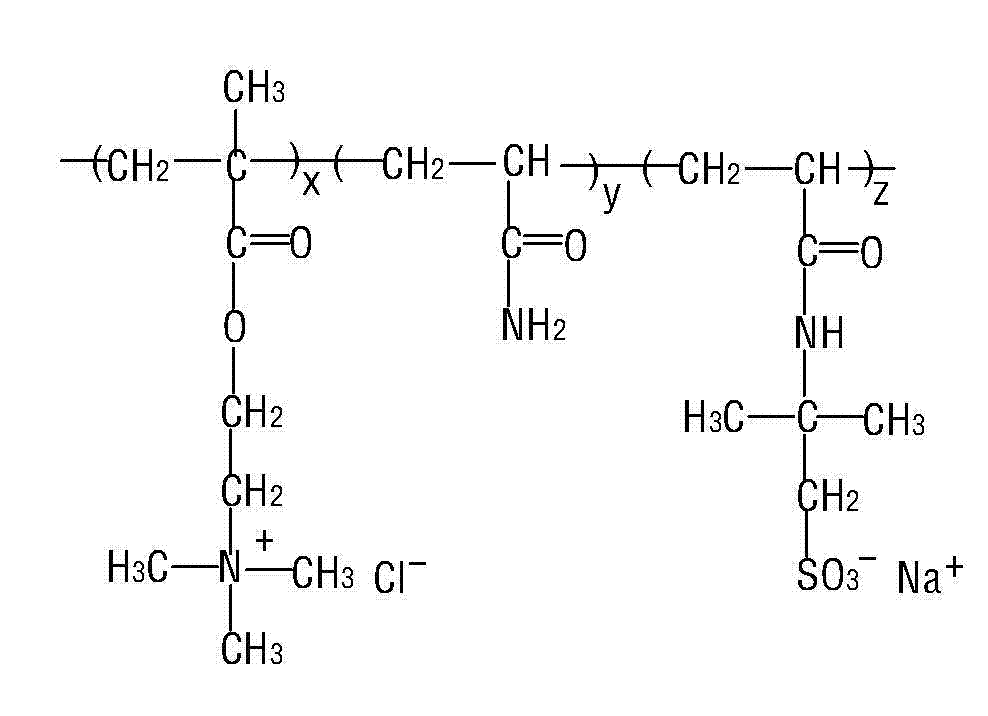

[0058] (1) Preparation of AM / DMC / AMPS polymer

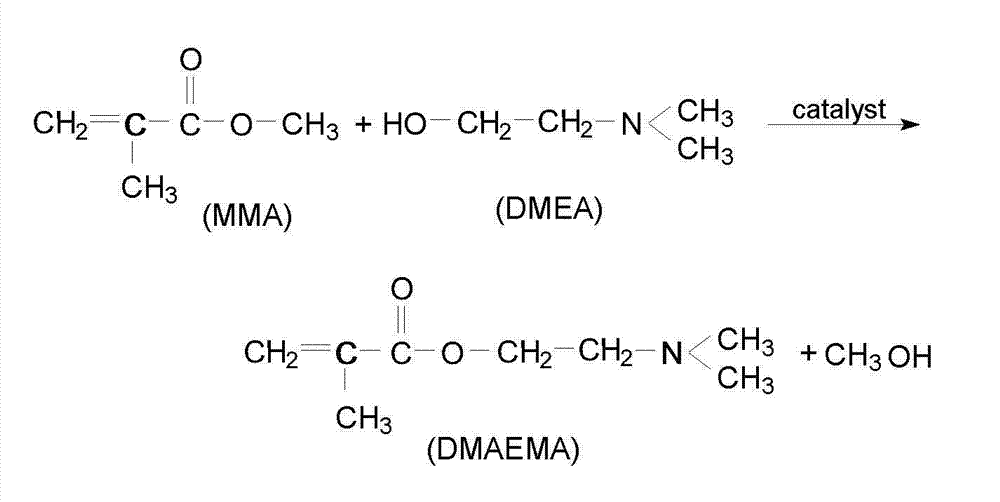

[0059] ① Preparation of dimethylaminoethyl methacrylate (DMAEMA)

[0060] A. In a 250ml three-necked bottle with a thermometer, a condenser, and a fractionating column, add quantitative N,N-dimethylethanolamine (DMAE), excess methyl methacrylate (MMA), and an appropriate amount of polymerization inhibitor phenothione Oxazine and an appropriate amount of catalyst tetrabutyl titanate. The molar ratio of DMEA:tetrabutyl titanate is 1:0.075, and the molar ratio of phenothiazine:DMAE is 0.0050:1.

[0061] B. Heat slowly to maintain the reaction temperature in the bottle at 95-98°C, and the temperature at the top of the fractionating column is 63-65°C. The generated methanol and excess methyl methacrylate form an azeotrope and distill it at a reflux ratio of 3:1. The reaction time is 4 ~5 hours.

[0062] C. After the reaction, reduce the pressure to 4×10 4 Pa, the temperature at the top of the tower is 40-45°C, the remaining met...

Embodiment 2

[0085] (1) 20% hydrochloric acid-based fracturing fluid formula

[0086] Hydrochloric acid: 20%

[0087] The thickener is AM / DMC / AMPS amphoteric polymer: 0.6%

[0088] The corrosion inhibitor is dodecyl pyridinium bromide: 2.0%

[0089] Drainage aid is methanol: 1.0%

[0090] Clay stabilizers are cationic polyquaternium salts of epichlorohydrin and dimethylamine: 0.5%

[0091] Iron ion stabilizer is ethylenediaminetetraacetic acid sodium salt: 1.0%

[0092] Water: 74.9%

[0093] Cross-link weight ratio: 100:2.0

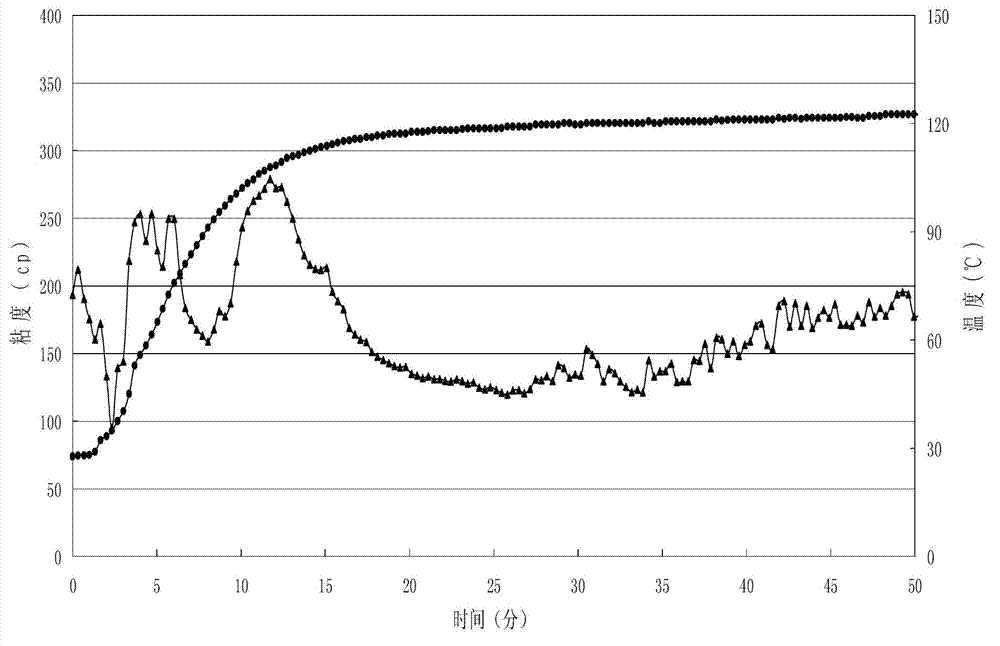

[0094] (2) Performance indicators of 20% hydrochloric acid-based fracturing fluid

[0095] The density is 1.10g / cm 3 , The viscosity of the base fluid at 20°C is 31.7mPa.s. The zirconium crosslinking agent with a crosslinking weight ratio of 100:2.0 is used for crosslinking, and the jelly is in 170s -1 , Viscosity at 120°C is 139mPa.s; gelation time is about 32s; ammonium persulfate is used as the breaker, and when the weight ratio of the breaker is 0.05% (50...

Embodiment 3

[0097] (1) 28% hydrochloric acid-based fracturing fluid formula

[0098] Hydrochloric acid: 28%

[0099] The thickener is AM / DMC / AMPS amphoteric polymer: 0.8%

[0100] Corrosion inhibitor is hexadecyl pyridinium bromide: 1.0%

[0101] Drainage aid is ethanol: 0.5%

[0102] Clay stabilizers are cationic polyquaternium salts of epichlorohydrin and dimethylamine: 0.5%

[0103] Iron ion stabilizer is sodium erythorbate: 1.0%

[0104] Water: 68.2%

[0105] Cross-link weight ratio: 100:2.5

[0106] (2) Performance indicators of 28% hydrochloric acid-based fracturing fluid

[0107] The density is 1.14g / cm 3 , The viscosity of the base fluid at 20°C is 47.8mPa.s. The zirconium cross-linking agent with a cross-linking weight ratio of 100:2.5 is used for cross-linking, and the jelly is in 170s -1 , Viscosity at 120°C is 186mPa.s; gelation time is about 18s; ammonium persulfate is used as the breaker, and when the weight ratio of the breaker is 0.1% (1000ppm), the viscosity of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com