Method for preparing efficient drilling fluid viscosity reducer by utilizing refuse leachate and application of efficient drilling fluid viscosity reducer

A technology for landfill leachate and drilling fluid, which is applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as low salinity resistance, insufficient humic acid modification and utilization, and poor viscosity reduction effect, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] According to a kind of preparation method of the high-efficiency drilling fluid viscosity reducer prepared by utilizing landfill leachate, it may further comprise the steps:

[0036] (1) Concentrate the landfill leachate stock solution through a biochemical membrane, then take the landfill leachate concentrate and add it to the concentrated sulfuric acid solution, and adjust the temperature of the reaction system to 140-180°C for constant temperature reaction for 6-12 hours. After the constant temperature reaction is completed , filtering out the solid matter in the reaction solution, and repeatedly washing the filtered solid matter with distilled water until the washing liquid is neutral, and drying the solid matter after the washing is completed;

[0037] (2) Take the above-mentioned dried solid matter and add it to an organic solvent, then add the acid chloride reactant and activator in sequence, adjust the pH value of the reaction system to 4-5, adjust the temperatur...

Embodiment 1

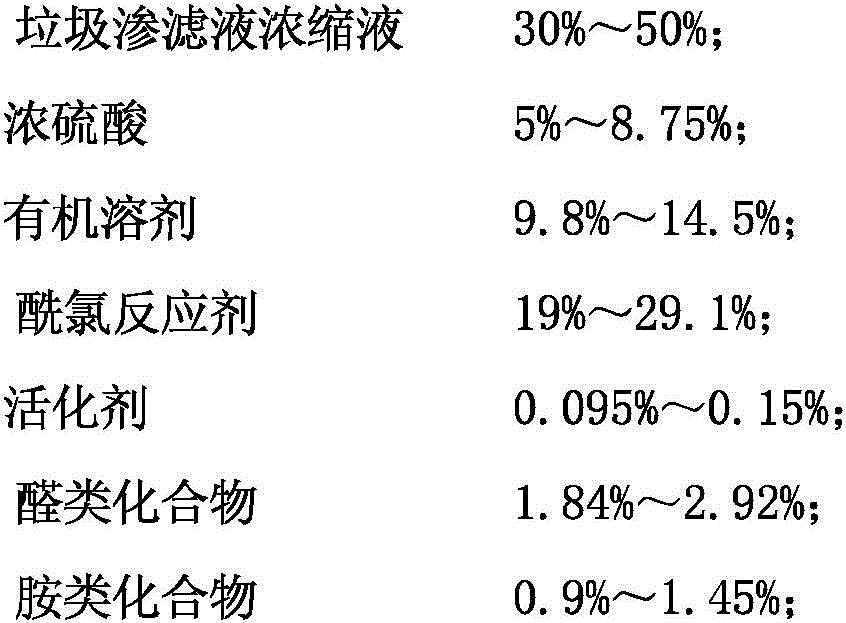

[0043] A high-efficiency drilling fluid viscosity reducer prepared from landfill leachate, its raw material composition and dosage are as follows:

[0044]

[0045] Preparation:

[0046] (1) Concentrate the landfill leachate stock solution through a biochemical membrane, then get 400Kg of landfill leachate concentrate with a solid content of 15% and add it to 60Kg of 98% concentrated sulfuric acid solution with a mass fraction, and adjust the temperature of the reaction system to 140 Perform constant temperature reaction at ℃ for 6 hours. After the constant temperature reaction is completed, filter out the solid matter in the reaction solution, and repeatedly wash the filtered solid matter with distilled water until the washing liquid is neutral. After the washing is completed, dry the solid matter;

[0047] (2) Take the above dried solid matter and add it to 100Kg of chloroform, then add 200Kg of oxalyl chloride and sodium hydroxide in a mass ratio of 1:1 to mix the mixtur...

Embodiment 2

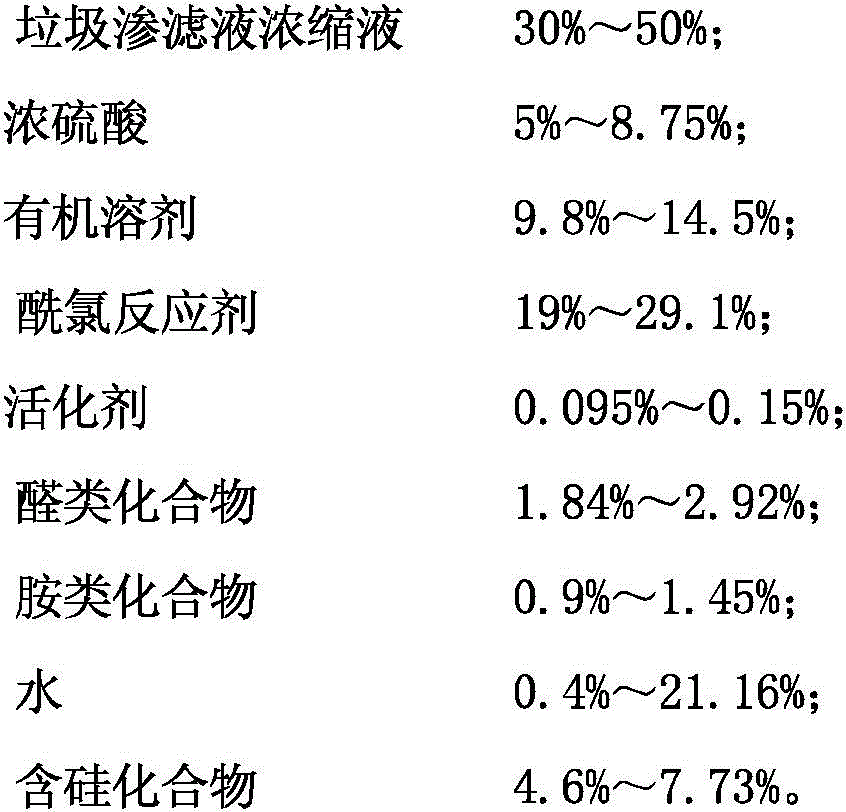

[0051] A high-efficiency drilling fluid viscosity reducer prepared from landfill leachate, its raw material composition and dosage are as follows:

[0052]

[0053] Preparation:

[0054] (1) The landfill leachate stoste is carried out concentrated treatment by biochemical membrane, then get 405Kg solid content and be that the landfill leachate concentrate of 18% joins in the concentrated sulfuric acid solution that 72.9Kg mass fraction is 98%, and reaction system temperature is adjusted to Perform a constant temperature reaction at 165°C for 8 hours. After the constant temperature reaction is completed, filter out the solid matter in the reaction solution, and repeatedly wash the filtered solid matter with distilled water until the washing liquid is neutral. After the washing is completed, dry the solid matter. ;

[0055] (2) Get the above-mentioned dried solid matter and join in the toluene of 125Kg, add 243Kg oxalyl chloride and sodium hydroxide successively under the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com