Sulfonated partially-hydrolyzed polyacrylamide weak gel and preparation method thereof

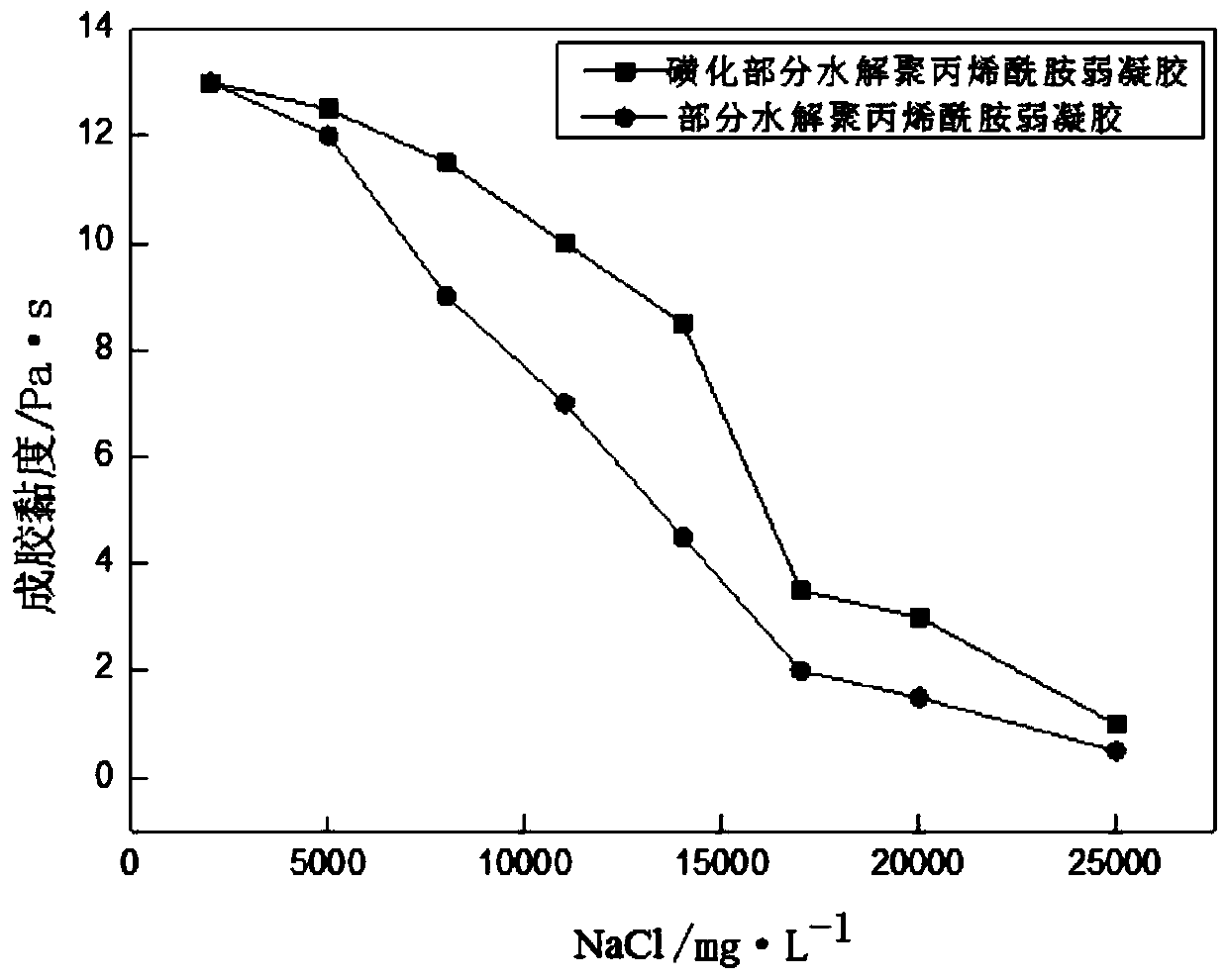

A technology of polyacrylamide and sulfonated part is applied in the field of sulfonated partially hydrolyzed polyacrylamide weak gel and its preparation, and achieves the effects of good salt resistance and diffusivity, good temperature resistance and salt resistance, and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of preparation method of sulfonated partially hydrolyzed polyacrylamide weak gel of the present invention, specifically comprises the following steps,

[0039] Step 1. Dissolve 3 g of sulfonated partially hydrolyzed polyacrylamide in 1000 mL of distilled water, stir to dissolve, and obtain solution a, and place it at room temperature for 6 hours to be matured;

[0040] Step 2, add 0.4g of water-soluble phenolic resin to 100mL of solution a, and stir well to make it evenly mixed to obtain mixed system A;

[0041] Step 3, dissolving 5 g of sodium hydroxymethyl lignosulfonate in 95 g of distilled water, and stirring evenly to obtain solution b;

[0042] Step 4, add 0.8g of solution b to 100g of mixed system A, and stir evenly to obtain mixed system B;

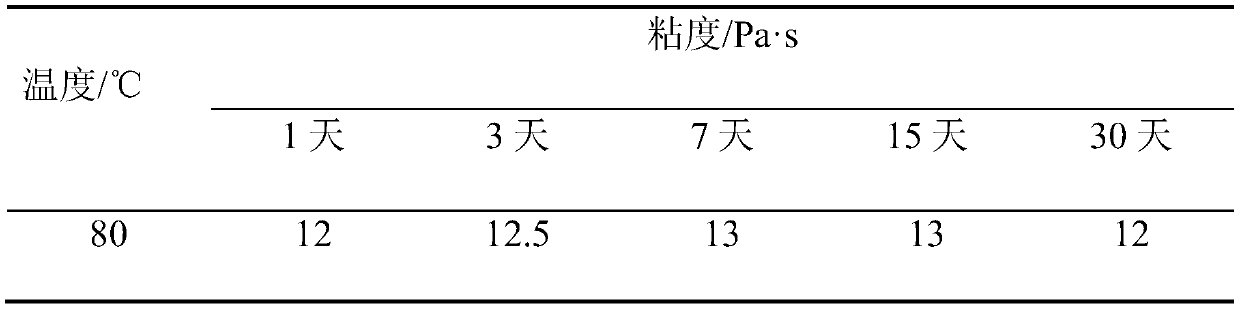

[0043] Step 5: Put the mixed system B in an airtight container, and place the container in an incubator at 80° C. for 24 hours to react to obtain a sulfonated partially hydrolyzed polyacrylamide weak gel with a visc...

Embodiment 2

[0050] A kind of preparation method of sulfonated partially hydrolyzed polyacrylamide weak gel of the present invention, specifically comprises the following steps,

[0051] Step 1: Dissolve 3.5g of sulfonated partially hydrolyzed polyacrylamide in 1000mL of distilled water, stir to dissolve, obtain solution a, and place it at room temperature for 6h to mature;

[0052] Step 2, add 0.45g of water-soluble phenolic resin to 100mL of solution a, and stir well to make it evenly mixed to obtain mixed system A;

[0053] Step 3, dissolving 5g of sodium hydroxymethyl lignosulfonate in 95g of distilled water, and stirring evenly to obtain solution b;

[0054] Step 4, adding 0.9g of solution b to 100g of mixed system A, and stirring evenly to obtain mixed system B;

[0055] Step 5: Put the mixed system B in an airtight container, and place the container in a thermostat at 100° C. for 24 hours to react to obtain a sulfonated partially hydrolyzed polyacrylamide weak gel with a viscosity ...

Embodiment 3

[0057] A kind of preparation method of sulfonated partially hydrolyzed polyacrylamide weak gel of the present invention, specifically comprises the following steps,

[0058] Step 1. Dissolve 3 g of sulfonated partially hydrolyzed polyacrylamide in 1000 mL of distilled water, stir to dissolve, and obtain solution a, and place it at room temperature for 6 hours to be matured;

[0059] Step 2, add 0.4g of water-soluble phenolic resin to 100mL solution a, and stir well to make it evenly mixed to obtain the mixed system A;

[0060] Step 3, dissolving 5g of sodium hydroxymethyl lignosulfonate in 95g of distilled water, and stirring evenly to obtain solution b;

[0061] Step 4, add 0.6g of solution b to 100g of mixed system A, and stir evenly to obtain mixed system B;

[0062] Step 5: Put the mixed system B in an airtight container, and place the container in a thermostat at 90°C for 24 hours to react to obtain a sulfonated partially hydrolyzed polyacrylamide weak gel with a viscosi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com