Oil field sewage flocculant and preparation method thereof

An oilfield sewage and flocculant technology, applied in separation methods, flocculation/sedimentation water/sewage treatment, mining wastewater treatment, etc., can solve the problems of clogging of cationic flocculants, affecting people's health, loss and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

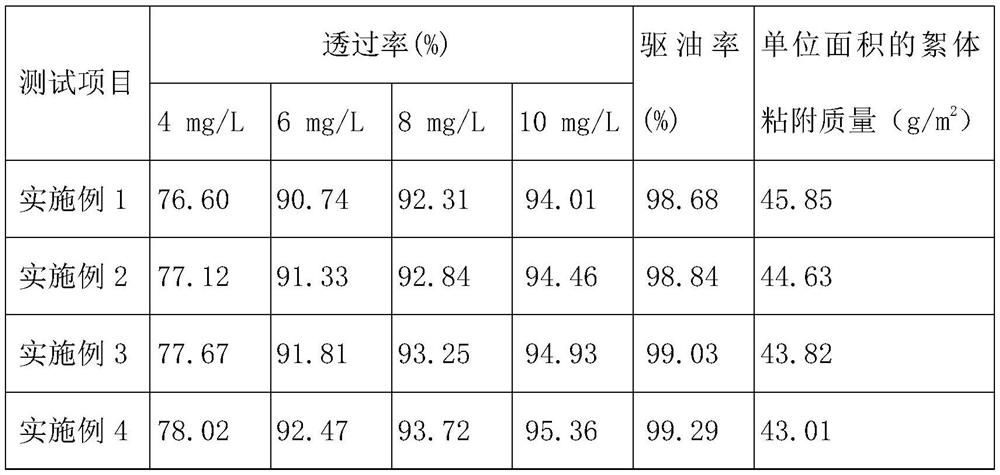

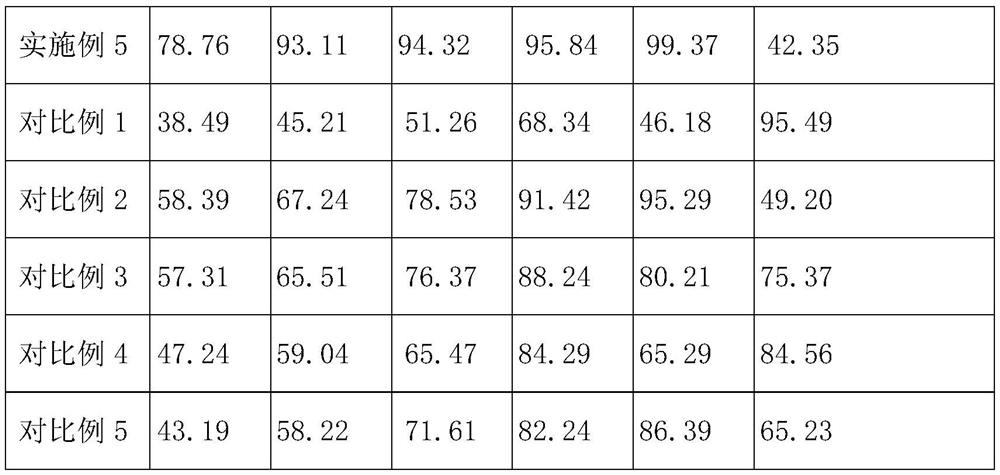

Examples

Embodiment 1

[0031] A flocculant for oilfield sewage, characterized in that it comprises the following components in mass percent: polymer 88%, silica airgel / diethylenetriaminopropyl trimethoxysilane / glycidyl trimethyl chloride Ammonium 12%; the polymer is composed of sunflower oleyl pyridine quaternary ammonium salt / ethylenediamine modified oxidized walnut powder, vinyl(trifluoromethyl)dimethylsilane and 2-acrylamido-methylpropanesulfonate polymerized by acid.

[0032] Preferably, the preparation method of the sunflower oil base pyridinium quaternary ammonium salt / ethylenediamine modified oxidized walnut powder comprises the steps:

[0033] Step I, preparation of oxidized walnut shell powder: crush the walnut shell, pass through a 50-mesh sieve, soak in water for 36 hours, filter, add 1mol / L sodium hydroxide solution, alkalinize for 24 hours, filter, and wash the filter cake with water , dried to obtain walnut shell powder, then added to isopropanol, ultrasonicated for 5 minutes, added s...

Embodiment 2

[0045] A flocculant for oilfield sewage, characterized in that it comprises the following components in mass percent: polymer 89%, silica airgel / diethylenetriaminopropyl trimethoxysilane / glycidyl trimethyl chloride Ammonium 11%; the polymer is composed of sunflower oleyl pyridinium quaternary ammonium salt / ethylenediamine modified oxidized walnut powder, vinyl(trifluoromethyl)dimethylsilane and 2-acrylamido-methylpropanesulfonate polymerized by acid.

[0046] Preferably, the preparation method of the sunflower oil base pyridinium quaternary ammonium salt / ethylenediamine modified oxidized walnut powder comprises the steps:

[0047] Step I, preparation of oxidized walnut shell powder: crush the walnut shell, pass through a 60-mesh sieve, soak in water for 39 hours, filter, add 1mol / L sodium hydroxide solution, alkalinize for 27 hours, filter, and wash the filter cake with water , dried to obtain walnut shell powder, then added to isopropanol, ultrasonicated for 6 minutes, added...

Embodiment 3

[0059] A flocculant for oilfield sewage, characterized in that it comprises the following components in mass percent: polymer 90%, silica airgel / diethylenetriaminopropyl trimethoxysilane / glycidyl trimethyl chloride Ammonium 10%; the polymer is composed of sunflower oleyl pyridinium quaternary ammonium salt / ethylenediamine modified oxidized walnut powder, vinyl(trifluoromethyl)dimethylsilane and 2-acrylamido-methylpropanesulfonate polymerized by acid.

[0060] Preferably, the preparation method of the sunflower oil base pyridinium quaternary ammonium salt / ethylenediamine modified oxidized walnut powder comprises the steps:

[0061] Step I, preparation of oxidized walnut shell powder: crush the walnut shell, pass through a 70-mesh sieve, soak in water for 42 hours, filter, add 1mol / L sodium hydroxide solution, alkalinize for 30 hours, filter, and wash the filter cake with water , dried to obtain walnut shell powder, then added to isopropanol, ultrasonicated for 7 minutes, added...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com