Preparation method of NASICON type lithium fast ion conductor

A lithium fast ion and conductor technology, applied in chemical instruments and methods, inorganic chemistry, electrical components, etc., can solve problems such as poor density, low phase purity of ceramic materials, and low electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

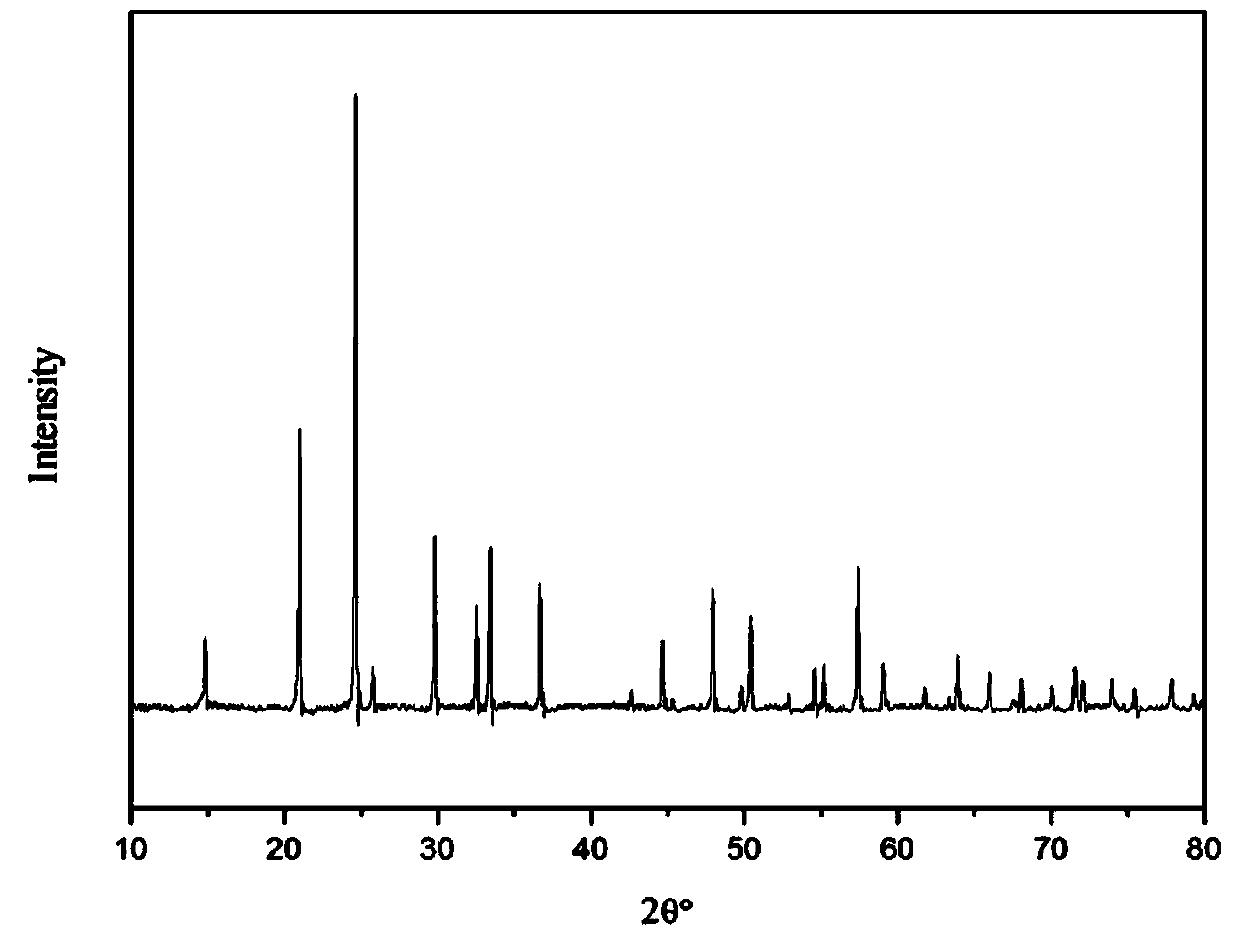

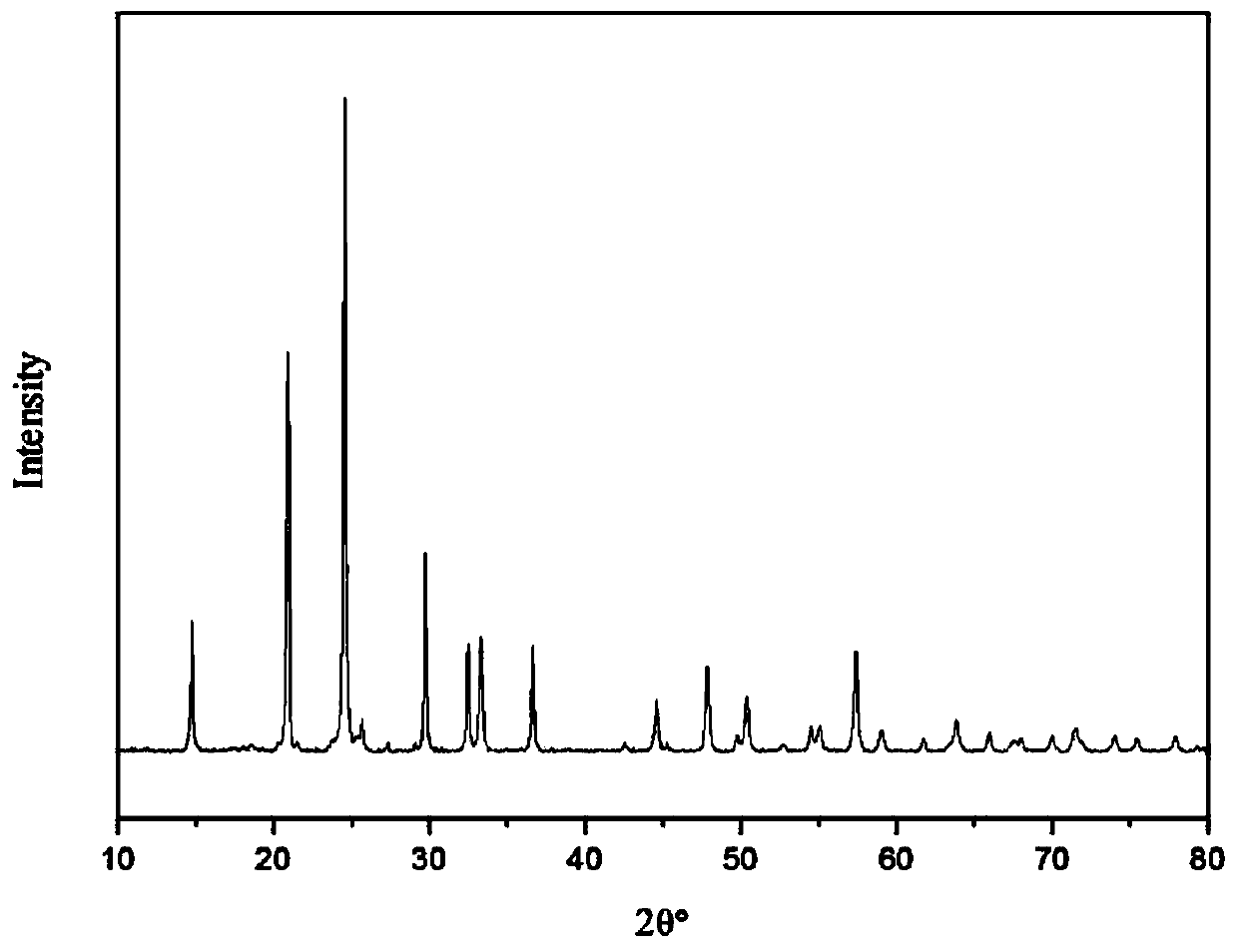

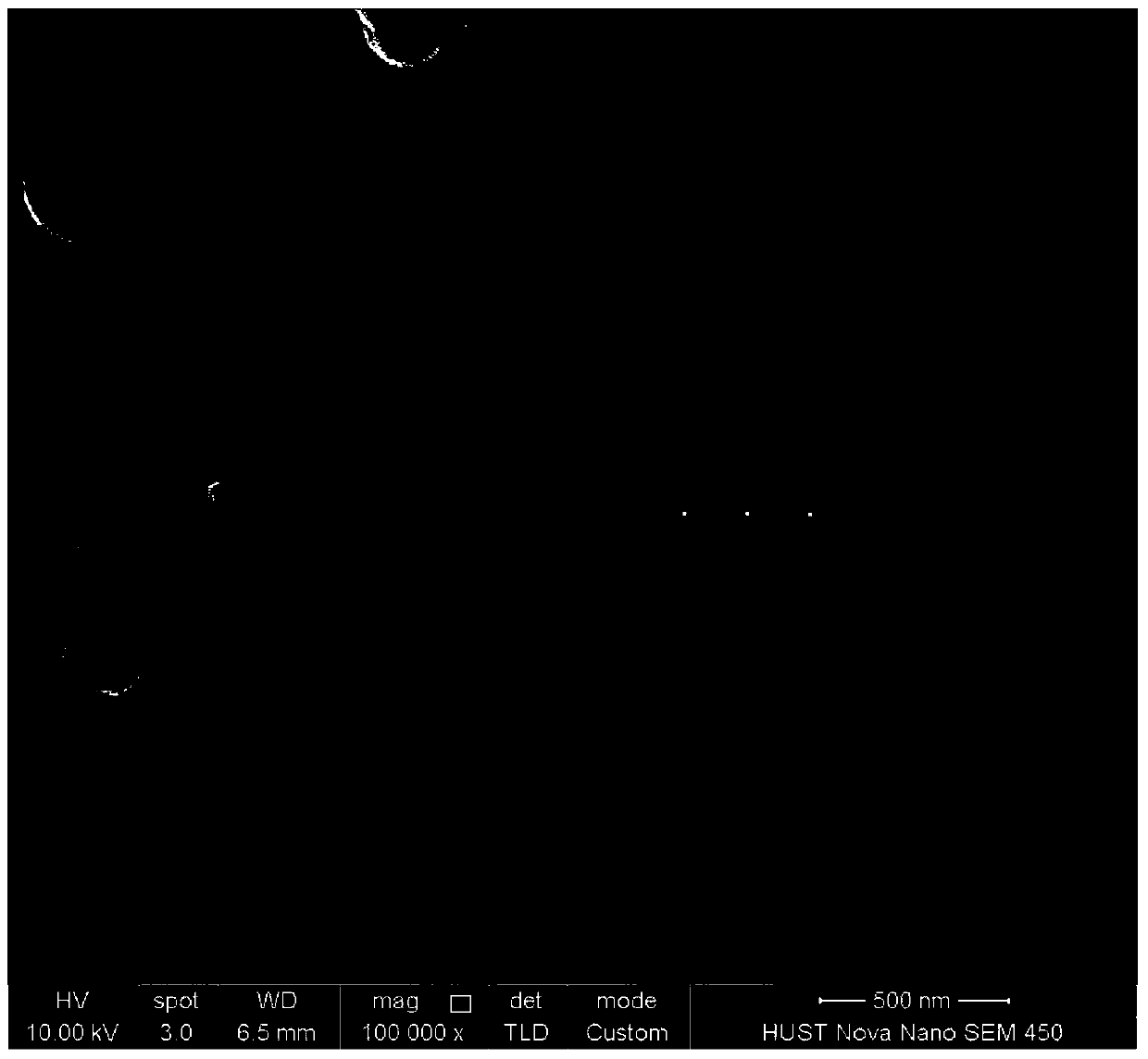

[0033] Adjust the oil bath temperature to 90°C, dissolve 17.6ml tetrabutyl titanate in 300ml, 0.2mol / L citric acid solution, and stir for 20 hours to form a sol. Lithium nitrate, aluminum nitrate, and ammonium dihydrogen phosphate were mixed according to the stoichiometric ratio of Li 1.1Al 0.1 Ti 1.9 (PO 4 ) 3 (x=0.1) ingredients, dissolved in 250ml, 0.2mol / L citric acid solution, slowly added to the sol, stirred for 0.5h, added 6.12ml of ethylene glycol, adjusted the oil bath temperature to 120°C, heated for 5h Take it out and form a gel. Put the gel in a corundum crucible in a muffle furnace, adjust the temperature to 150°C, and keep it warm for 8 hours to make it into a dry gel. Grinding the xerogel into powder particles in an agate mortar (in the present invention, the powder particles have no size requirement, as long as they are in granular form). The powder particles were placed in the crucible in the muffle furnace again, the heating rate was 2°C / min, the temper...

Embodiment 2

[0036] Adjust the oil bath temperature to 90°C, dissolve 17.6ml tetrabutyl titanate in 300ml, 0.2mol / L citric acid solution, and stir for 20 hours to form a sol. Lithium nitrate, aluminum nitrate, and ammonium dihydrogen phosphate were mixed according to the stoichiometric ratio of Li 1.2 Al 0.2 Ti 1.8 (PO 4 ) 3 (x=0.2) Ingredients, dissolved in 250ml, 0.2mol / L citric acid solution, slowly added to the sol, stirred for 0.5h, added 6.12ml of ethylene glycol, adjusted the oil bath temperature to 120°C, heated for 5h Take it out and form a gel. Put the gel in a corundum crucible in a muffle furnace, adjust the temperature to 150°C, and keep it warm for 8 hours to make it into a dry gel. Grind the xerogel into powder particles in an agate mortar. The powder particles were placed in the crucible in the muffle furnace again, the temperature was adjusted to 500°C, the heating rate was 2°C / min, and the temperature was kept for 4h, and then the temperature was raised to 800°C, an...

Embodiment 3

[0039] Adjust the oil bath temperature to 90°C, dissolve 17.6ml tetrabutyl titanate in 300ml, 0.2mol / L citric acid solution, and stir for 20 hours to form a sol. Lithium nitrate, aluminum nitrate, and ammonium dihydrogen phosphate were mixed according to the stoichiometric ratio of Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 (x=0.3) ingredients, after dissolving in 250ml, 0.2mol / L citric acid solution, slowly add to the sol, after stirring for 0.5h, add 6.12ml of ethylene glycol, adjust the oil bath temperature to 120°C, heat for 5h Take it out and form a gel. Put the gel in a corundum crucible in a muffle furnace, adjust the temperature to 150°C, and keep it warm for 8 hours to make it into a dry gel. Grind the xerogel into powder particles in an agate mortar. The powder particles were placed in the crucible in the muffle furnace again, the heating rate was 2°C / min, the temperature was adjusted to 500°C, and kept for 4h, then the temperature was raised to 800°C, and kept for 2h. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com