Preparation method of nitrogen-doped hierarchical pore carbon materials

A technology of multi-level pores and carbon materials, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve problems such as poor thermal stability, underdeveloped pore structure, and low nitrogen content, and achieve The effect of stable quality, tunable specific surface area, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Preparation of aluminum-based metal-organic framework complexes

[0028] Soak 1.5kg of cleaned banana peel fragments in 2L of 1.0mol / L aluminum nitrate aqueous solution, and heat to dry at 70°C to obtain a yellow aluminum-based metal-organic framework complex material.

[0029] 2. Preparation of nitrogen-doped hierarchically porous carbon materials

[0030] Dissolve 1 g of Planck F127 with a relative molecular weight of 12600 in 50 mL of absolute ethanol, add 5 g of aluminum-based metal-organic framework complexes, stir at room temperature for 24 hours, then heat to 120 ° C, and thermally polymerize for 24 hours. The reaction product was calcined at 800°C for 3 hours under nitrogen protection, washed with 20% hydrofluoric acid aqueous solution and distilled water, and dried at 100°C to obtain a nitrogen-doped hierarchical porous carbon material.

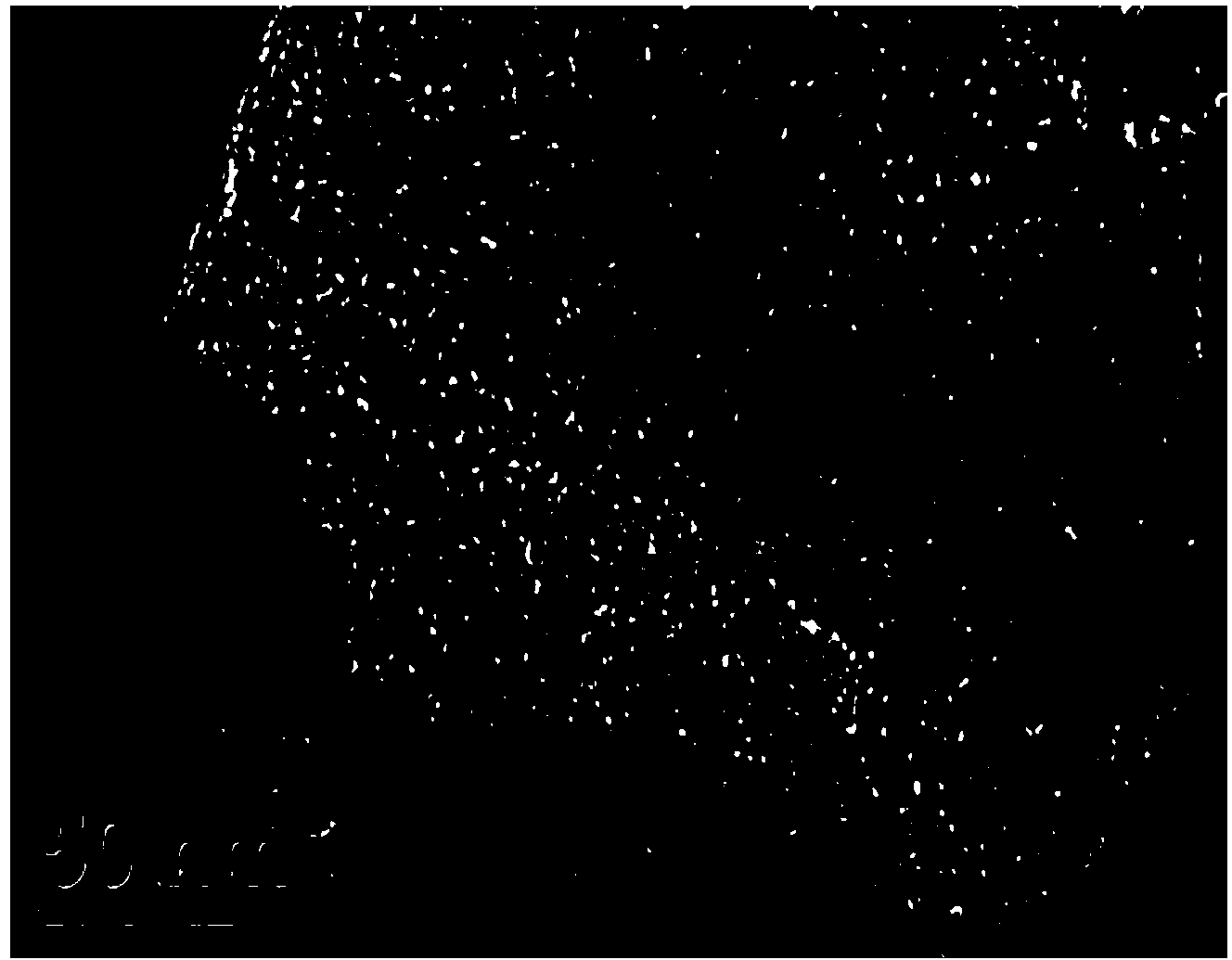

[0031] Depend on figure 1 It can be seen that the prepared nitrogen-doped hierarchical porous carbon material obviously...

Embodiment 2

[0033] In the step 1 of preparing the aluminum-based metal-organic framework complex in this example, the concentration of the aluminum nitrate aqueous solution used is 0.6 mol / L. In the step 2 of preparing the nitrogen-doped hierarchical porous carbon material, the reaction product is under the protection of nitrogen, Calcined at 700° C. for 3 hours, and the other steps were the same as in Example 1 to prepare a nitrogen-doped hierarchically porous carbon material.

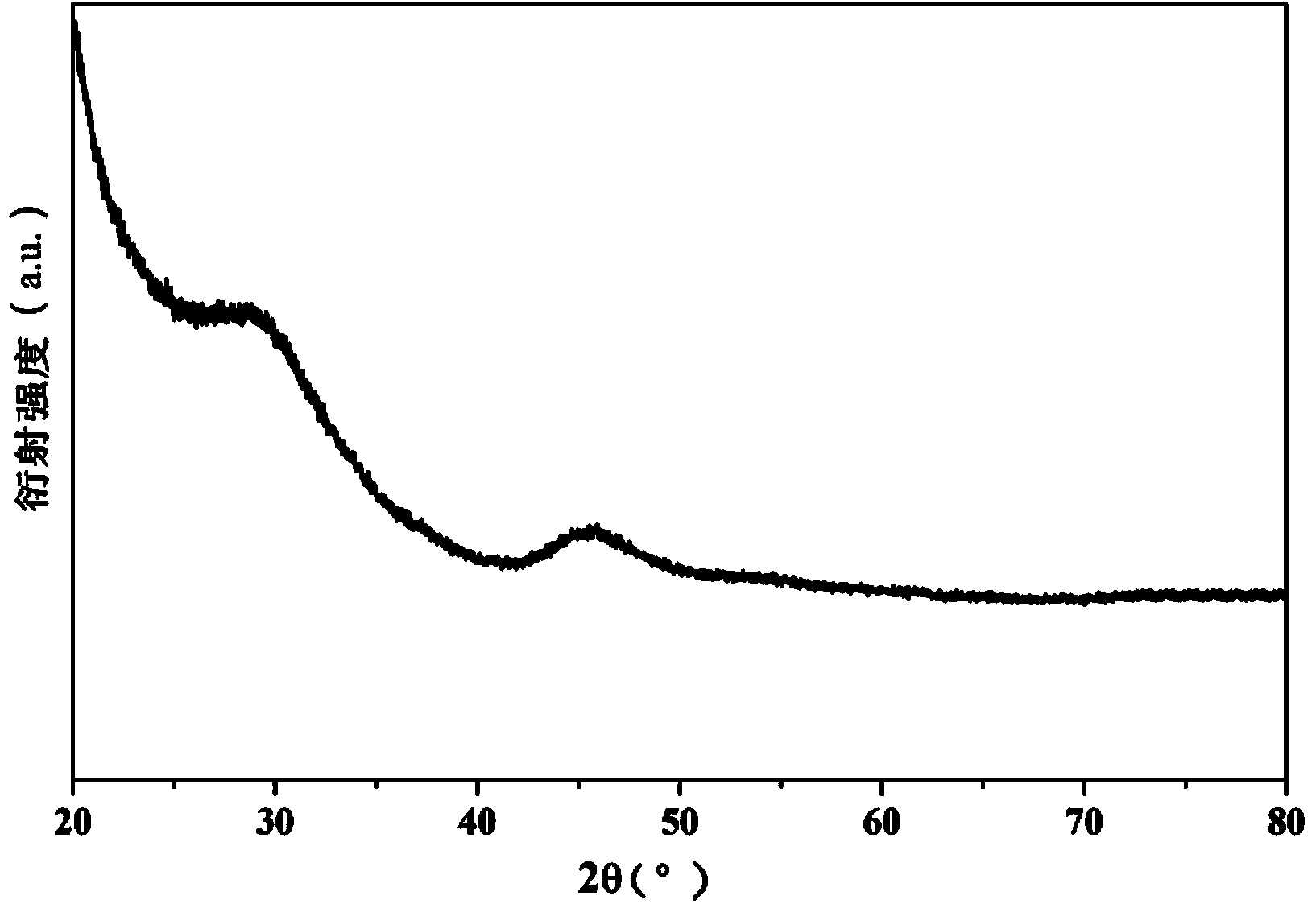

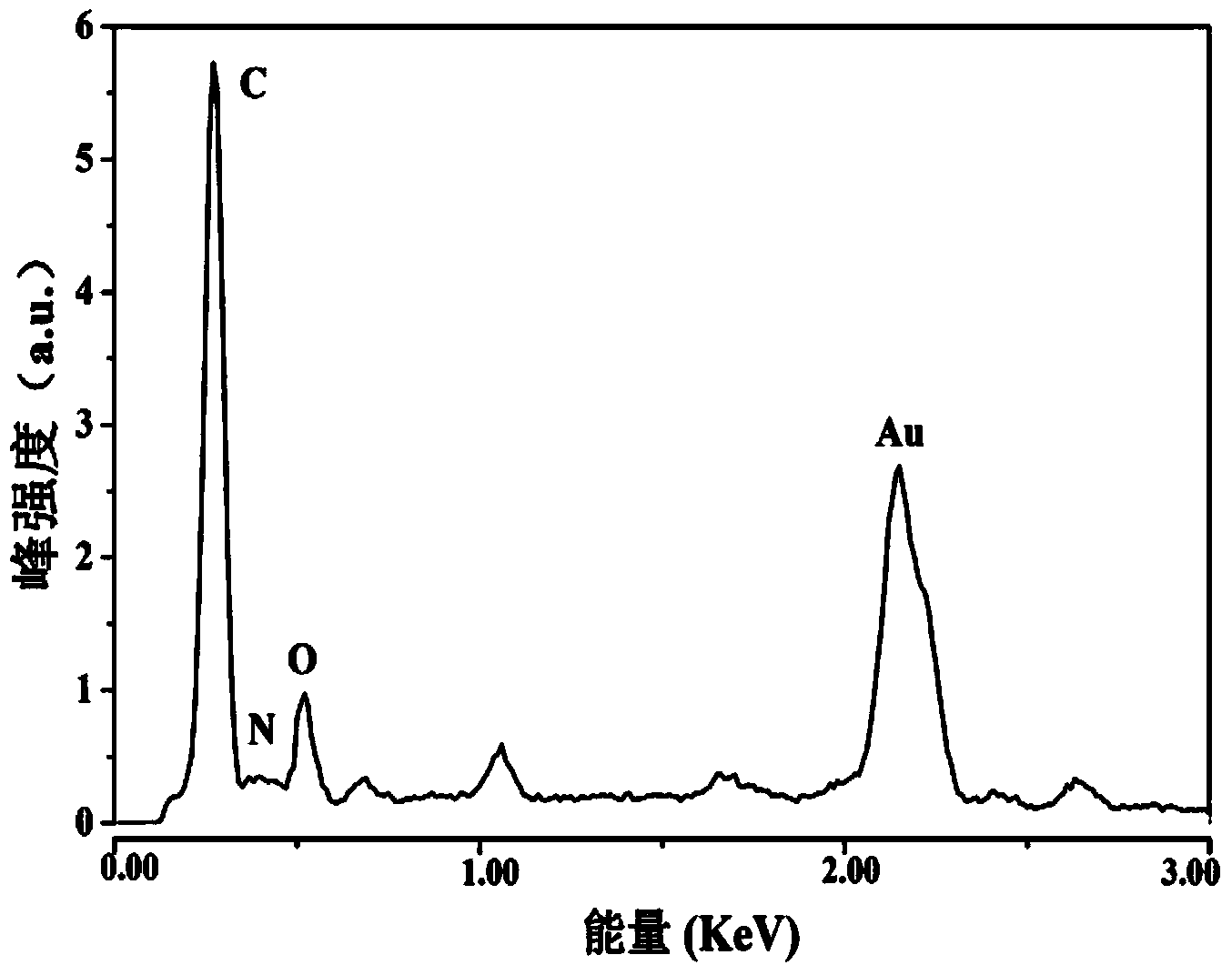

[0034] Depend on Figure 4 It can be seen that the prepared carbon material is a nano-hierarchical porous carbon material formed by different pore structures connected to each other. X-ray photoelectron spectroscopy analysis results show that the obtained carbon material is composed of carbon, oxygen and nitrogen species ( Figure 5 ), this result fully proves that the carbon material obtained under this condition is a nitrogen-doped hierarchical porous carbon material.

Embodiment 3

[0036] In step 2 of preparing nitrogen-doped hierarchically porous carbon materials in this example, 1 g of Planck F127 with a relative molecular mass of 12600 was completely dissolved in 50 mL of absolute ethanol, 20 g of aluminum-based metal-organic framework complexes were added, and the Stir for 24 hours, other steps are the same as in Example 1, and prepare nitrogen-doped hierarchical porous carbon material (see Figure 6 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com