Alumina coating method of lithium ion battery positive electrode material

A technology for lithium ion batteries and cathode materials, which is applied in the field of preparation of electrode active materials, can solve the problems of slow solid-phase diffusion, difficulty in uniform mixing, and practical application effects, and achieves the effects of improving cycle stability and reducing capacity decay.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

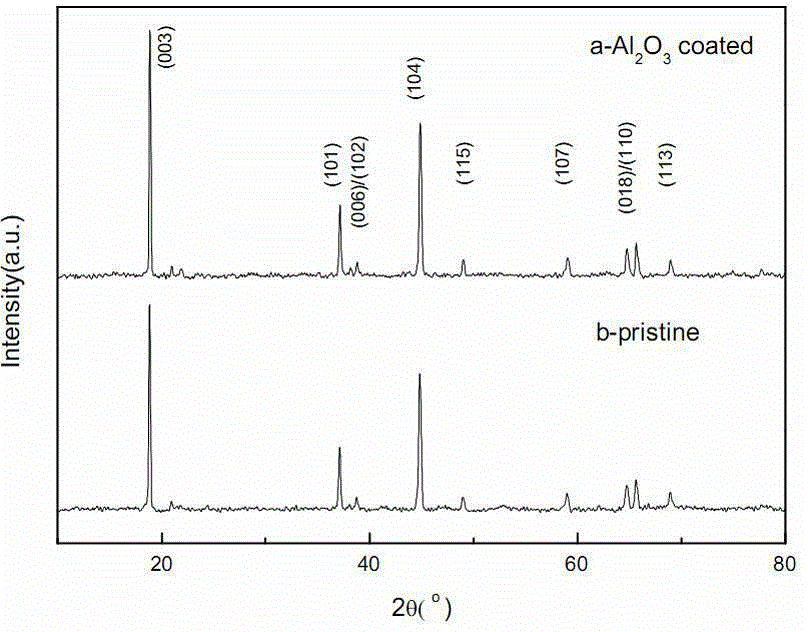

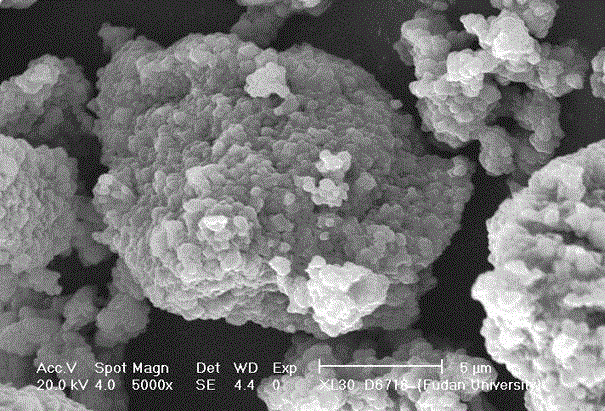

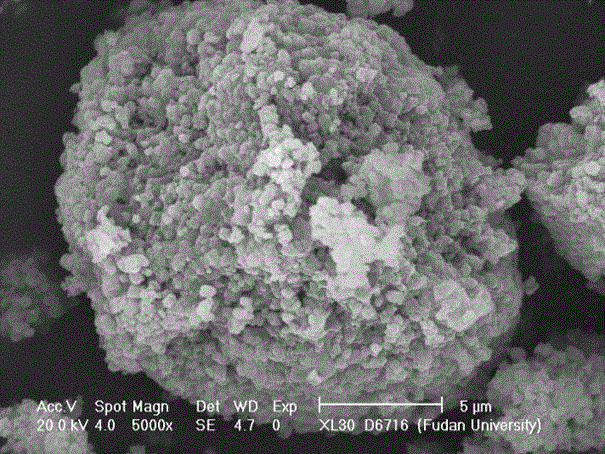

Image

Examples

Embodiment 1

[0020] Embodiment one: the lithium cobalt oxide (LiCoO 2 ) material suspended in Al(NO 3 ) 3 In the solution, the cathode material and aluminum nitrate nonahydrate (AlNO 3 9H 2 O) with a mass ratio of 100:23, under continuous stirring, slowly add ammonia water dropwise to make the Al in the solution 3+ All ions are Al(OH) 3 Precipitate in the form, add ammonia water dropwise at a rate of 10 seconds per drop. The mixed precipitate was filtered, washed, and heated at 300 °C for 4 h in an air-atmosphere muffle furnace to obtain Al 2 o 3 Coated lithium cobalt oxide cathode material.

Embodiment 2

[0021] Embodiment two: with the spinel type lithium manganese oxide (LiMn 2 o 4 ) material is the coating object, and the coating is carried out with reference to the method of Example 1. The positive electrode material and aluminum nitrate nonahydrate (AlNO 3 9H 2 The mass ratio of O) is 100:23, and other conditions are unchanged with reference to Example 1. The obtained precipitate is heated at 270° C. for 5 hours in a muffle furnace in an air atmosphere to obtain Al 2 o 3 Coated spinel lithium manganese oxide cathode material.

Embodiment 3

[0022] Embodiment three: with the layered lithium manganese oxide (Li 2 MnO 3 ) material is the coating object, and the coating is carried out with reference to the method of Example 1. The positive electrode material and aluminum nitrate nonahydrate (AlNO 3 9H 2 The mass ratio of O) is 100:23, and other conditions are unchanged with reference to Example 1. The obtained precipitate is heated at 330° C. for 2 hours in an air atmosphere muffle furnace to obtain Al 2 o 3 Coated layered lithium manganese oxide cathode material. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com