Preparation method of alumina-coated hexagonal boron nitride composite powder for self-lubricating cutter material

A technology of hexagonal boron nitride and composite powder is applied in the field of powder metallurgy, which can solve the problems of reducing the mechanical strength of the tool matrix, reducing the mechanical properties of the tool, and increasing the wear of the tool.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

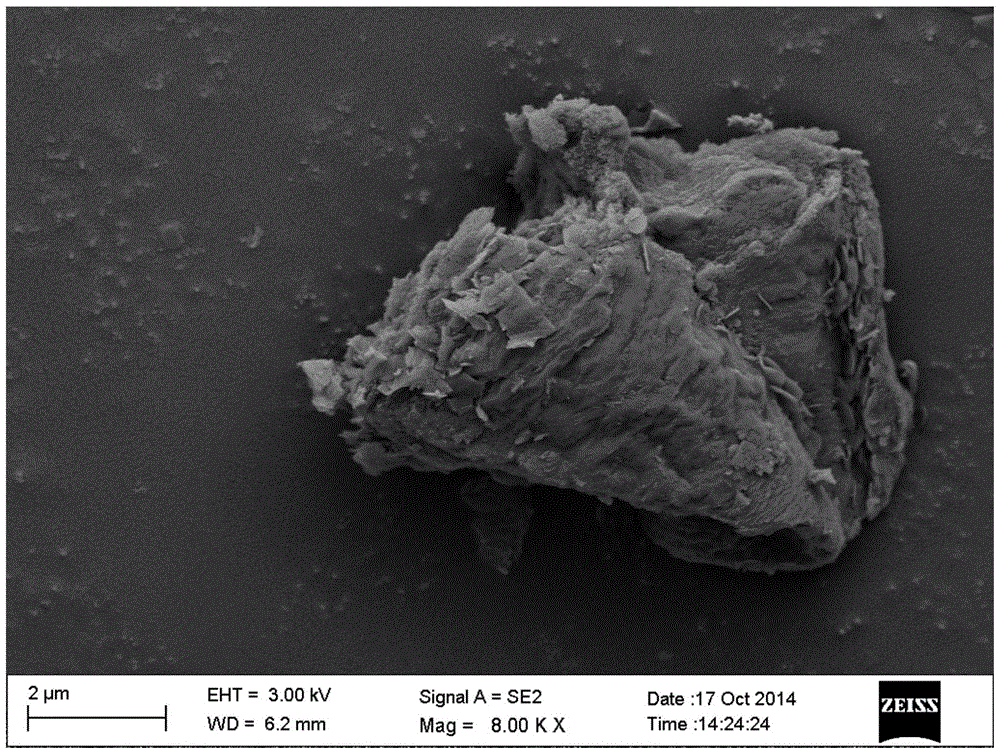

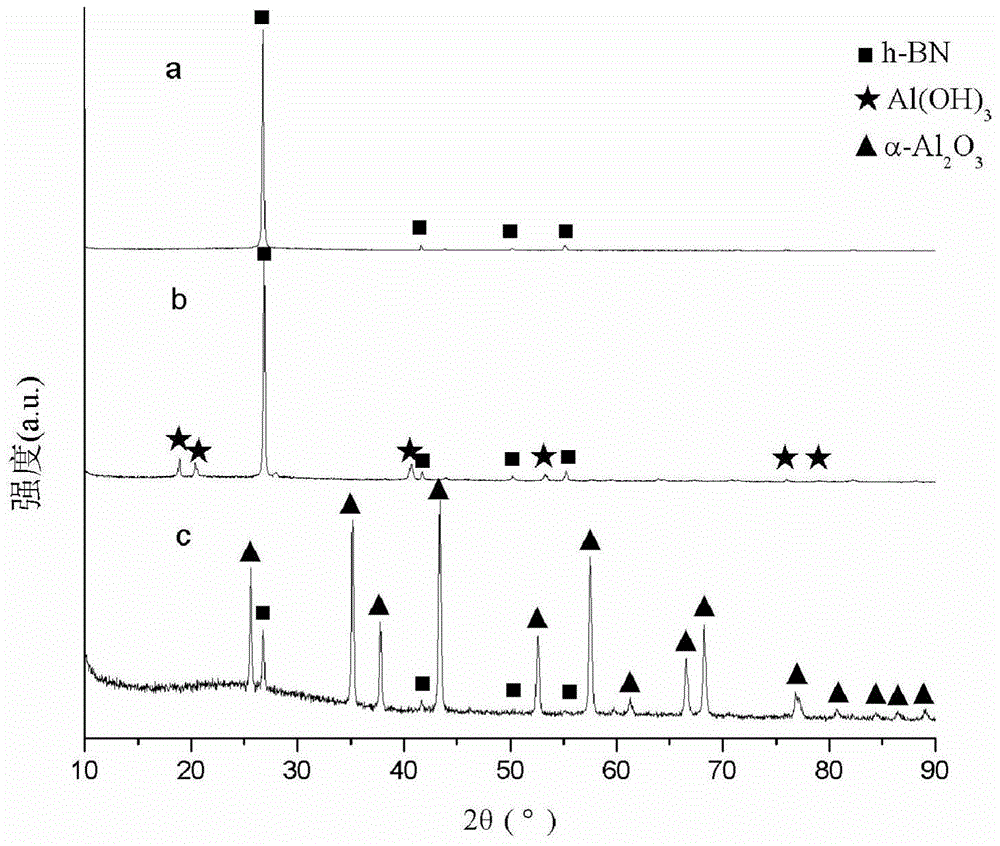

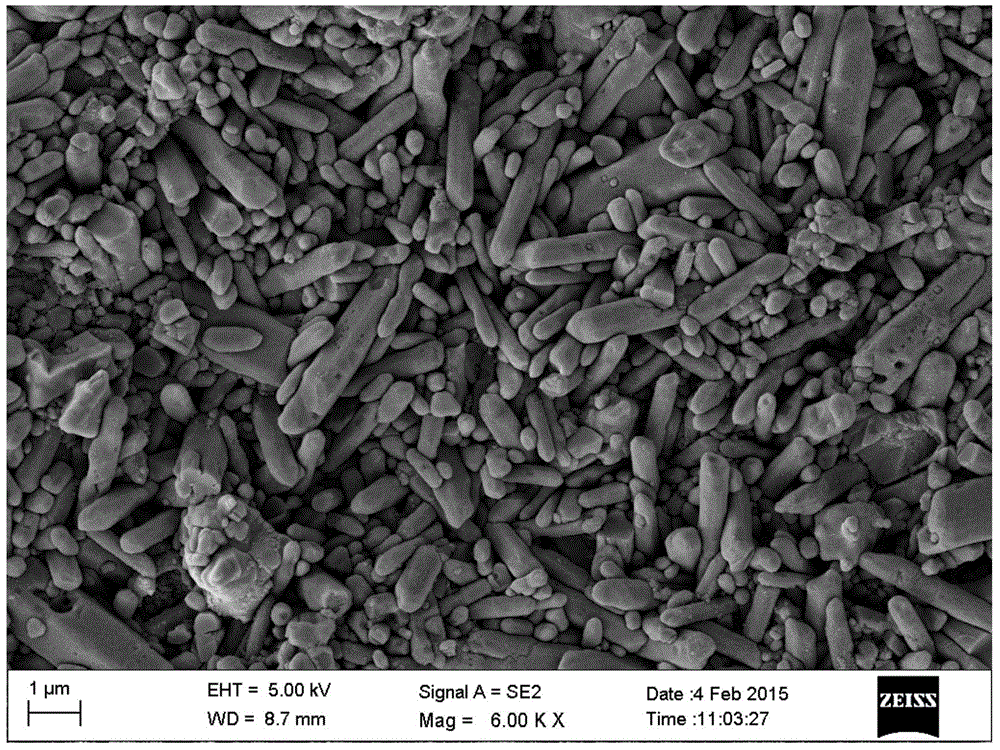

[0033] Embodiment 1, the preparation method of aluminum oxide coated hexagonal boron nitride powder, the steps are as follows:

[0034] Weigh 0.5 g of hexagonal boron nitride powder with an average particle diameter (D50) of 4 μm and dispersant polyethylene glycol 6000 accounting for 4% by mass of the hexagonal boron nitride powder, and mix them in 100 mL of distilled water to form a suspension. 10 mL of acetic acid-sodium acetate buffer solution with a pH of 4.5 was added to the suspension. The suspension was ultrasonically dispersed for 10 min, and magnetically stirred in a digital heat collector magnetic stirrer and heated to 35°C. Suspension I was obtained.

[0035] Weigh an appropriate amount of aluminum nitrate nonahydrate and configure it into Al 3+ The aluminum nitrate solution with a concentration of 0.15 mol / L is dropped into the uniformly dispersed hexagonal boron nitride suspension I, and the amount of the aluminum nitrate solution added is calculated according t...

Embodiment 2

[0039] Embodiment 2, the preparation method of aluminum oxide coated hexagonal boron nitride powder, the steps are as follows:

[0040] Weigh 0.5 g of hexagonal boron nitride powder with an average particle diameter D50 of 4 μm and dispersant polyethylene glycol 6000 accounting for 4% by mass of the hexagonal boron nitride powder, and mix them in 100 mL of distilled water to form a suspension. 10 mL of acetic acid-sodium acetate buffer solution with a pH of 4.5 was added to the suspension. The suspension was ultrasonically dispersed for 10 min, and magnetically stirred in a digital display collector type magnetic stirrer and heated to 40°C. Suspension I was obtained.

[0041] Take by weighing an appropriate amount of aluminum nitrate nonahydrate, configure the aluminum nitrate solution of 0.2mol / L concentration, drop in the uniformly dispersed hexagonal boron nitride suspension I, the addition of the aluminum nitrate solution is according to the molar ratio BN: Al= 1:1 count...

Embodiment 3

[0044] Embodiment 3: application experiment

[0045] A self-lubricating tool with aluminum oxide-coated hexagonal boron nitride composite powder is added. The volume percentage of raw materials is: micron silicon nitride 62%, nano silicon nitride 10%, micron titanium carbide 10%, alumina 3.2%, yttrium oxide 4.8%, alumina-coated hexagonal boron nitride 10% (the product prepared in Example 1).

[0046] The components were weighed respectively, and micron silicon nitride, micron titanium carbide suspension and nano silicon nitride suspension were first prepared with an appropriate amount of absolute ethanol as the dispersion medium, and dispersed by ultrasonic for 15 min. Mix the obtained micron silicon nitride, micron titanium carbide suspension and nano silicon nitride suspension, then add aluminum oxide and yttrium oxide to obtain a mixed suspension, stir thoroughly and ultrasonically disperse for 15 minutes to obtain a multiphase suspension. Pour the above-mentioned multipha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com