Carbuncle type yellow fluorescent material Y3Al5O12:Ce,Li preparation method

A y3al5o12, fluorescent material technology, applied in the field of fluorescent materials, can solve problems such as unsatisfactory luminous efficiency, and achieve the effect of improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Select x=0.01 and y=0.04, according to Y (3-x-y) Ce x Li y Al 5 o 12 According to the molar ratio of the raw materials, the corresponding yttrium nitrate, cerium nitrate, lithium nitrate and aluminum nitrate were weighed and dissolved in deionized water to obtain a solution. After fully mixing, add citric acid, the number of moles of citric acid is 2.4 times of that of aluminum nitrate. Adjust the pH value of the solution to 6, heat and evaporate in a water bath, control the temperature at 80°C, and keep stirring until a transparent colloid is formed. This sol is then further heated to form a gel. The precursor powder was obtained after the gel was burned in an environment of 200 °C. The precursor powder was then calcined at 900 °C.

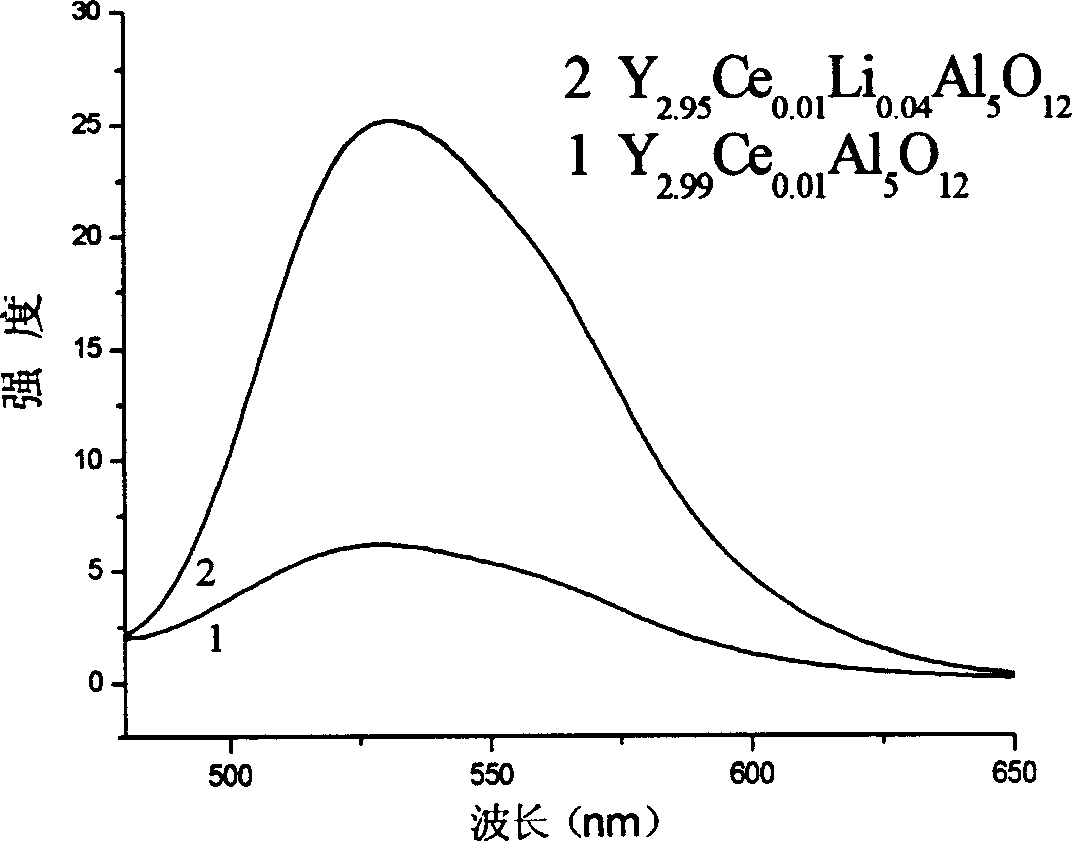

[0028] figure 1 is Y 3 Al 5 o 12 : Ce, Li Example 1 and Y 3 Al 5 o 12 : Comparison of fluorescence spectra of Ce. It can be seen from the figure that in Y 3 Al 5 o 12 : Doping Li in Ce increases its luminous intensity abo...

Embodiment 2

[0030] Select x=0.04 and y=0.08, according to Y (3-x-y) Ce x Li y Al 5 o 12 According to the molar ratio of the raw materials, the corresponding yttrium nitrate, cerium nitrate, lithium nitrate and aluminum nitrate were weighed and dissolved in deionized water to obtain a solution. Add citric acid after fully mixing, and the molar number of citric acid is 3.2 times of that of aluminum nitrate. Adjust the pH value of the solution to 5, heat and evaporate in a water bath, control the temperature at 70°C, and keep stirring until a transparent colloid is formed. This sol is then further heated to form a gel. The precursor powder was obtained after the gel was burned in an environment of 220 °C. The precursor powder was then calcined at 1200 °C.

Embodiment 3

[0032] Select x=0.1 and y=0.01, according to Y (3-x-y) Ce x Li y Al 5 o 12 According to the molar ratio of the raw materials, the corresponding yttrium nitrate, cerium nitrate, lithium nitrate and aluminum nitrate were weighed and dissolved in deionized water to obtain a solution. After fully mixing, add citric acid, the number of moles of citric acid is 1.6 times of that of aluminum nitrate. Adjust the pH value of the solution to 5, heat and evaporate in a water bath, control the temperature at 70°C, and keep stirring until a transparent colloid is formed. This sol is then further heated to form a gel. The precursor powder was obtained after the gel was burned in an environment of 240 °C. The precursor powder was then calcined at 850 °C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com