Water-based drilling fluids using latex additives

A water-based drilling fluid, drilling fluid technology, applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as difficulty in achieving the required balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of Fluid Intermediates

[0038] components

[0039] NEW DRILL PLUS

[0040] Fluid with latex and NEWDRILL PLUS is light brown. Add LD8 to control foaming. The resulting mixture was hot rolled at 150°F (66°C) for 4 hours. The final pH was 10.75.

Embodiment 2

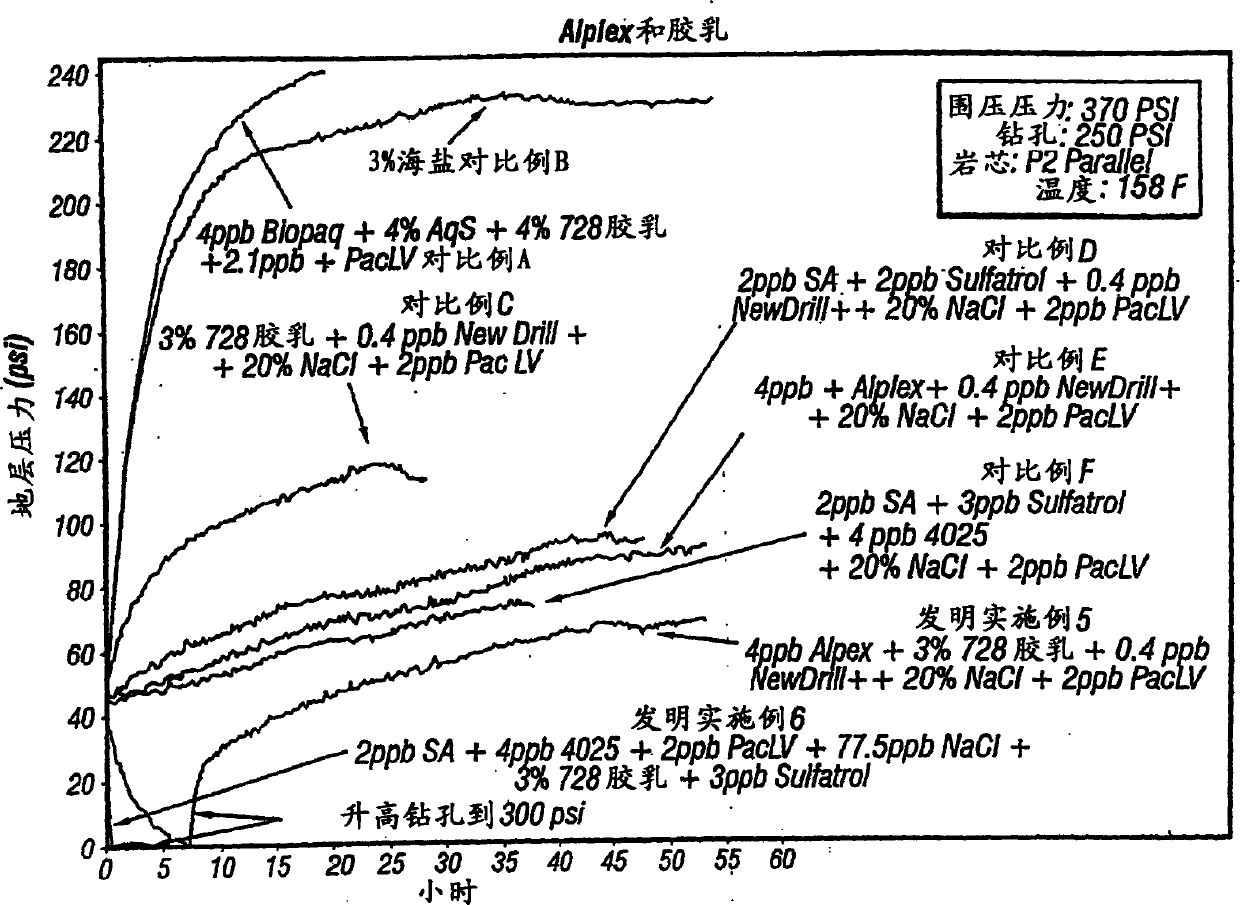

[0042] Determination of shale pressure penetration

[0043] The pore pressure transmission (PPT) device was referenced to a 1500 psi (10300 kPa) Hassler cell, which is a drill core rod design of 2.5 cm to 7.5 cm in length and 2.5 cm in diameter. Hassler cells are cylinders with pistons inserted into each end. The drill core is held between the two pistons. A rubber bushing is placed around the core and piston to seal around the core and prevent flow around the core. Pressurizing the outside of the bushing creates a good seal. These tests used drill cores with a diameter of 25 mm and a length of 25 mm.

[0044] The low pressure side (formation side) of the drill core is fitted with a 1 liter, 2000psi (13800kPa) stainless steel reservoir to provide back pressure. The high pressure side of the core is connected to two similar reservoirs, one for the microbore fluid and the other for the test fluid. The pressure in each reservoir was controlled using manual regulators fed thr...

Embodiment 3

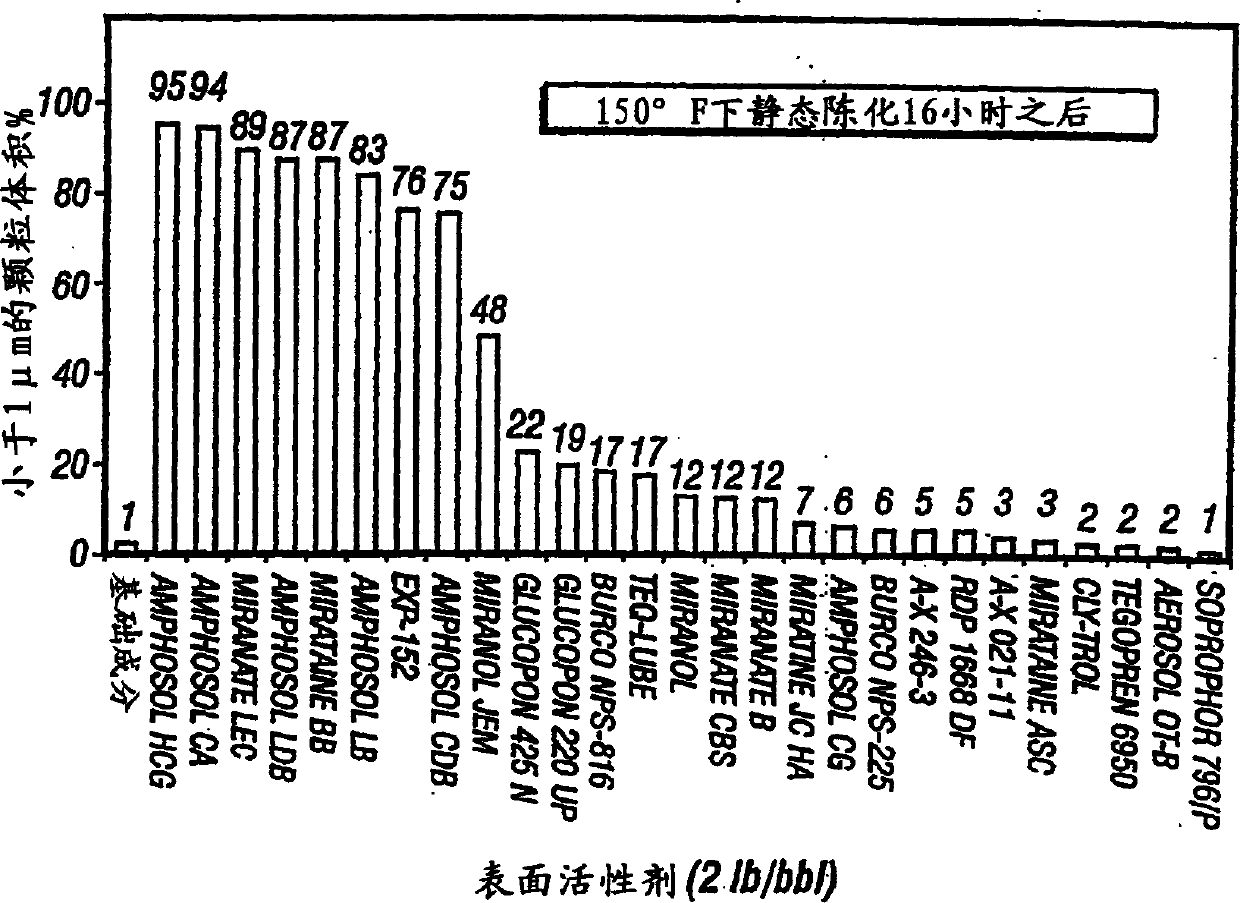

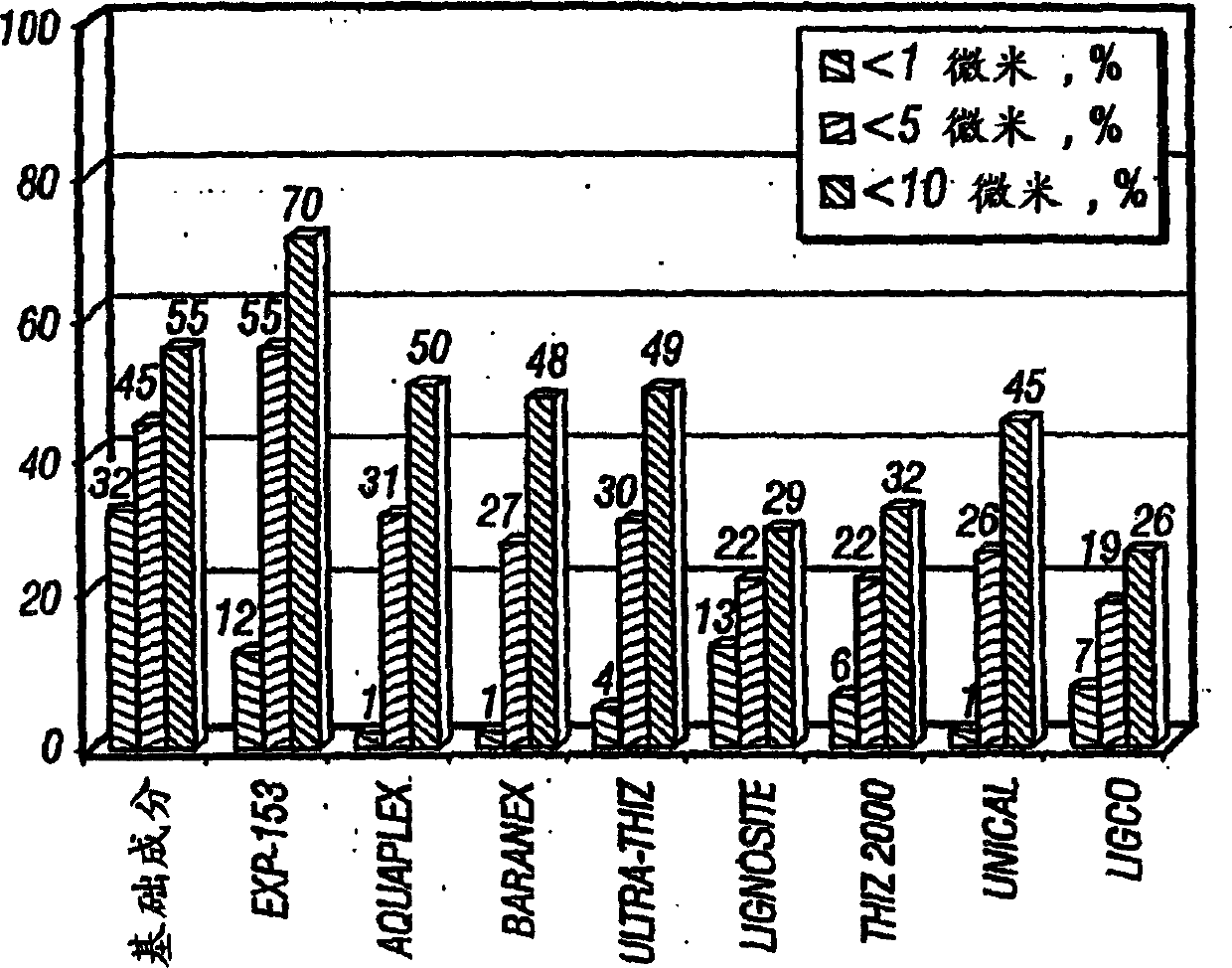

[0055] components

[0056] Sodium aluminate and AIRFLEX 728 latex were mixed together and allowed to sit over the weekend. The mixture was then hot rolled at 150°F (66°C) for 2 hours. Then salt and polymer are added. The order of addition to the sodium aluminate / latex mixture was: PHPA (partially hydrolyzed polyacrylamide; NEWDRILL PLUS), then mix, then half the salt, then MILPAC LV, then the other half of the salt. Heat roll the mixture overnight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com