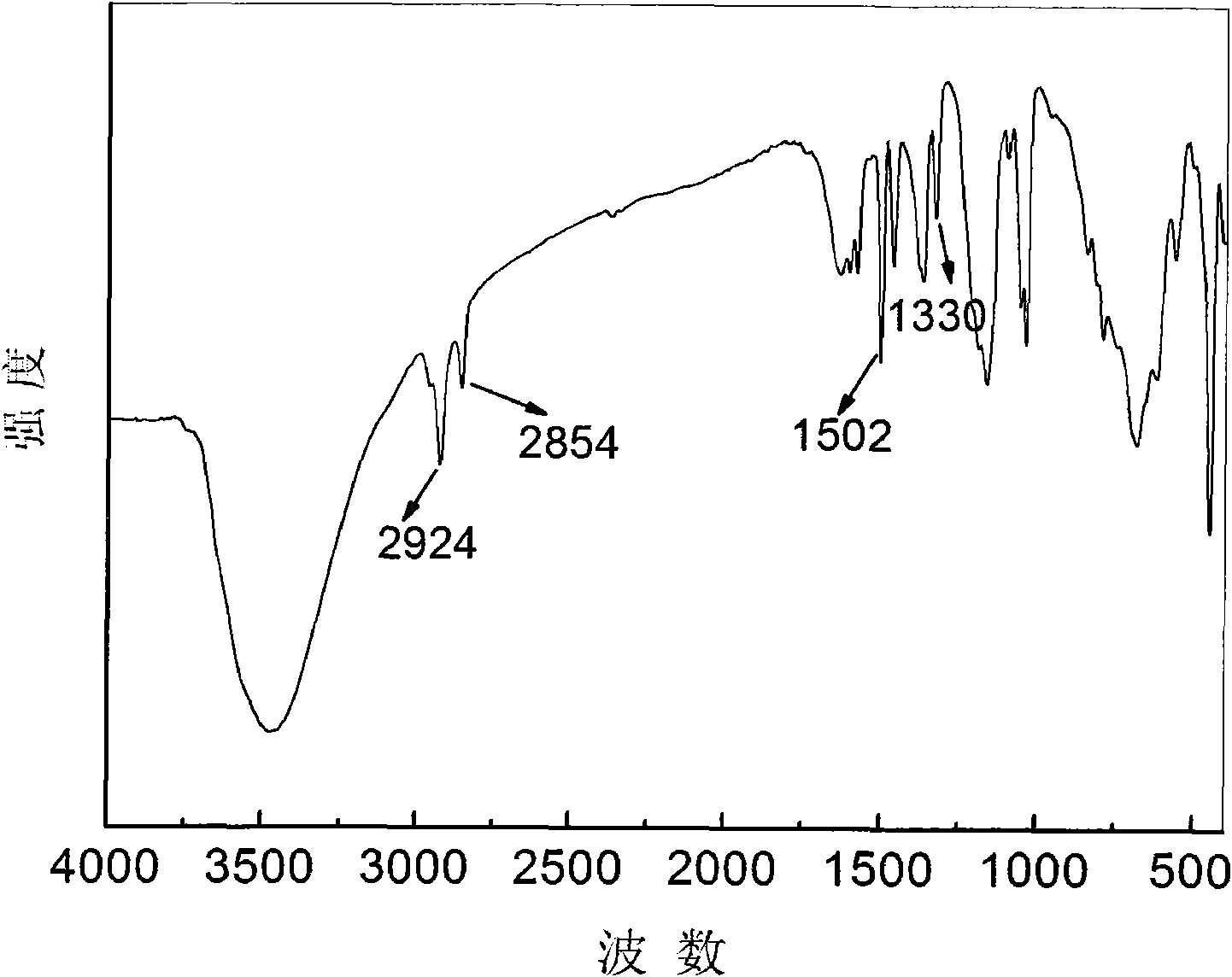

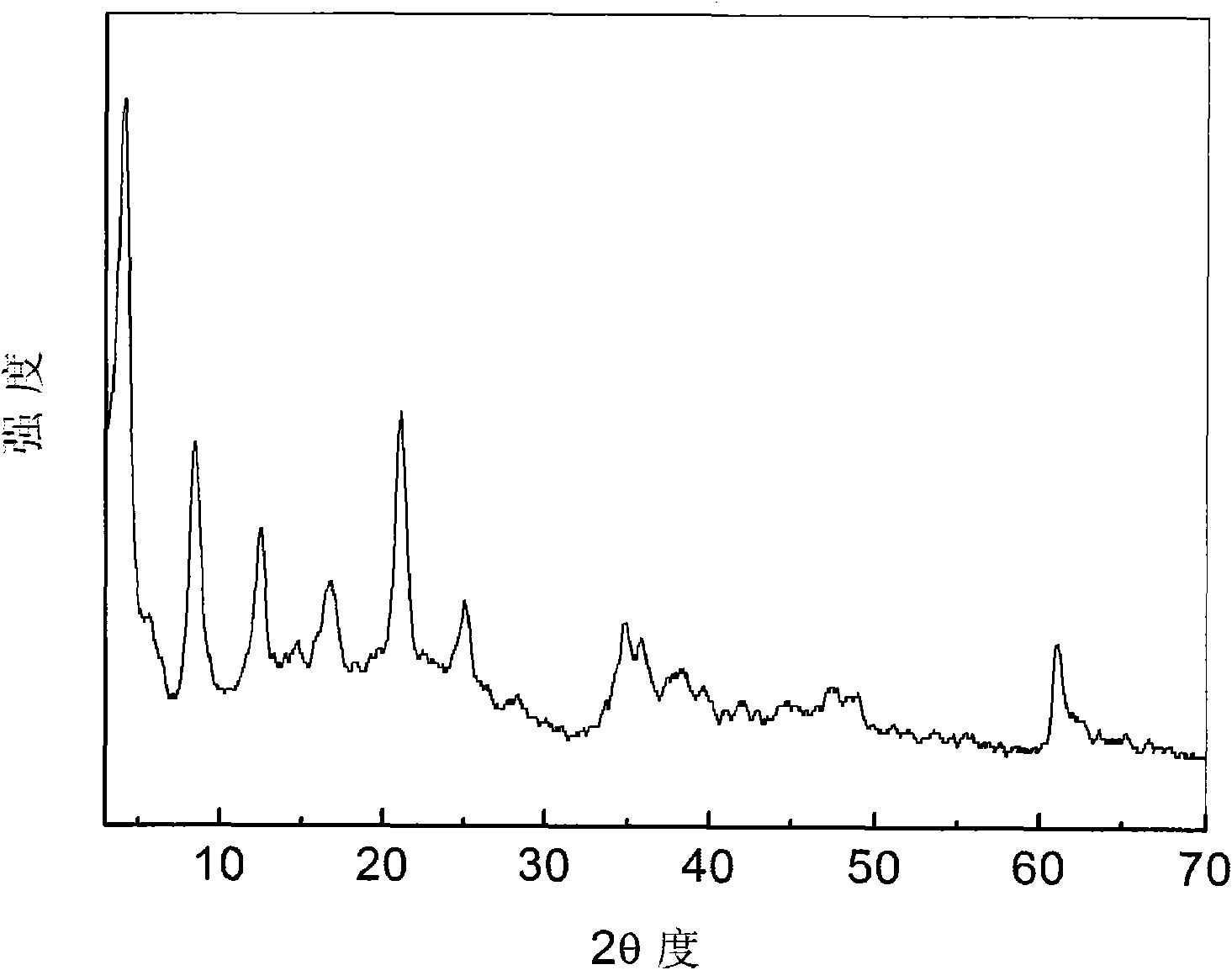

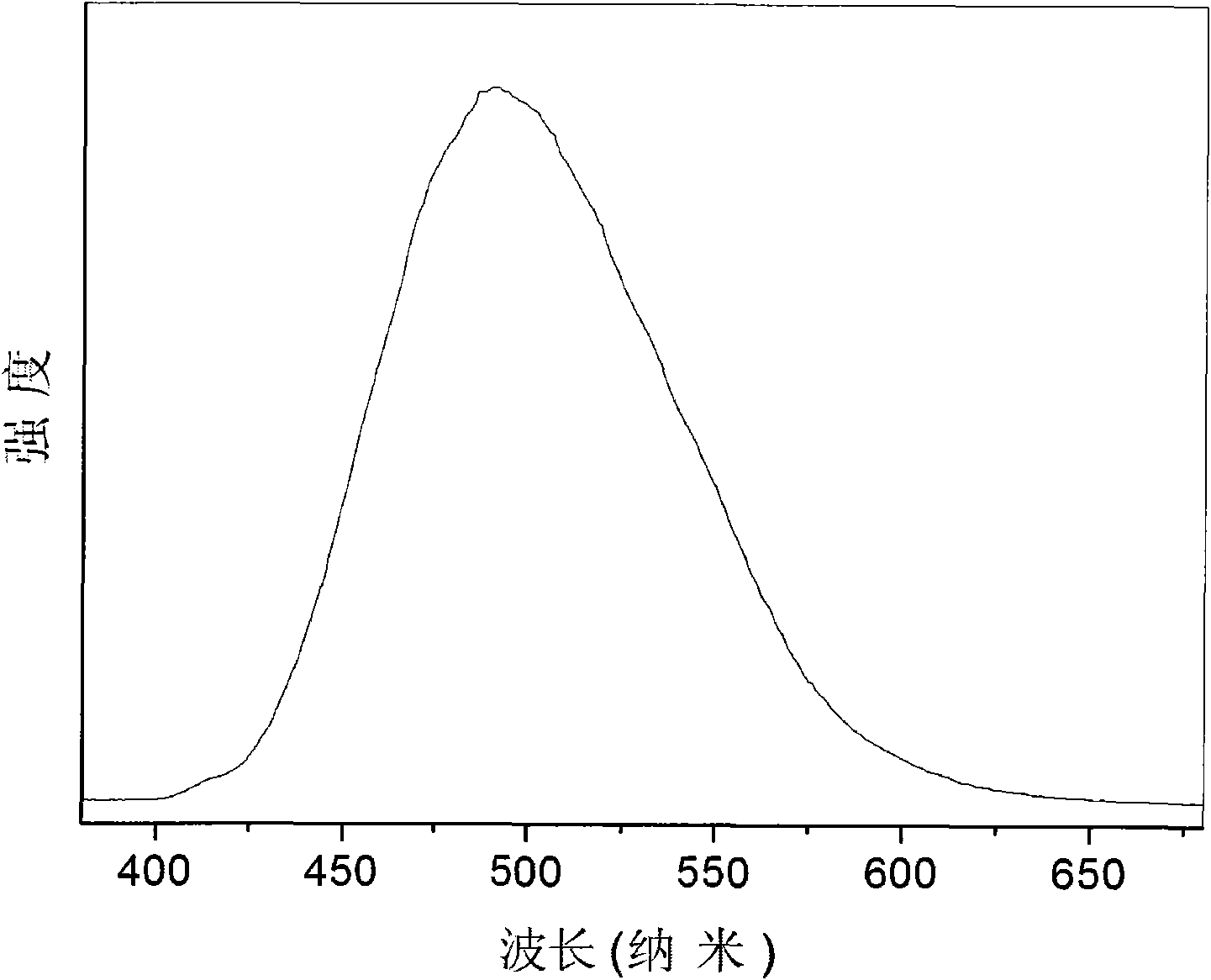

Tri(8-hydroxyquinoline-5-sulfonate) aluminum complex anion intercalated hydrotalcite composite luminescent material and preparation method thereof

An anion intercalation, hydroxyquinoline technology, applied in luminescent materials, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Weigh 0.769g Mg(NO 3 ) 2 ·6H 2 O and 0.563g Al(NO 3 ) 3 9H 2 O dissolved in 50ml to remove CO 2 , deionized water, to obtain solution A, Mg 2+ / Al 3+ The molar ratio is 2:1, Mg 2+ The concentration is 0.06M;

[0035] 2. Dissolve 0.036g of tris(8-hydroxyquinoline-5-sulfonate)aluminum and 0.371g of sodium dodecylsulfonate in 50ml of water to obtain solution B, tris(8-hydroxyquinoline-5- Sodium sulfonate) the concentration of aluminum is 0.0009M;

[0036] 3. Mix solution A and solution B to obtain solution C, and pour solution C into a four-necked flask;

[0037] 4. Dissolve 0.8g NaOH in 40ml to remove CO 2 , deionized water, the NaOH solution was passed through a constant pressure funnel, and under the condition of nitrogen protection, slowly added dropwise to the four-necked flask equipped with solution C until the pH value was 9.5 to obtain slurry D, which was transferred to a 100ml high-pressure The reaction kettle was placed in an oven at 110°C for 20 h...

Embodiment 2

[0041] 1. Weigh 0.769g Mg(NO 3 ) 2 ·6H 2 O and 0.563g Al(NO 3 ) 3 9H 2 O dissolved in 50ml to remove CO 2 , deionized water, to obtain solution A, Mg 2+ / Al 3+ The molar ratio is 2:1, Mg 2+ The concentration is 0.06M;

[0042] 2. Dissolve 0.267g of tris(8-hydroxyquinoline-5-sulfonate)aluminum and 0.136g of sodium dodecylsulfonate in 50ml of water to obtain solution B, tris(8-hydroxyquinoline-5- Sodium sulfonate) the concentration of aluminum is 0.0067M;

[0043] 3. Mix solution A and solution B to obtain solution C, and pour solution C into a four-necked flask;

[0044] 4. Dissolve 0.8g NaOH in 20ml to remove CO 2 , deionized water, the NaOH solution was passed through a constant pressure funnel, and under nitrogen protection conditions, slowly added dropwise to the four-necked flask equipped with solution C until the pH value was 10 to obtain slurry D, which was transferred to a 100ml high-pressure The reaction kettle was placed in an oven at 130°C for 24 hours; ...

Embodiment 3

[0048] 1. Weigh 1.154g Mg(NO 3 ) 2 ·6H 2 O and 0.563g Al(NO 3 ) 3 9H 2 O dissolved in 50ml to remove CO 2 , deionized water, to obtain solution A, Mg 2+ / Al 3+ The molar ratio is 3:1, Mg 2+ The concentration is 0.09M;

[0049] 2. Dissolve 0.392g of tris(8-hydroxyquinoline-5-sulfonate)aluminum and 0.008g of sodium dodecylsulfonate in 50ml of water to obtain solution B, tris(8-hydroxyquinoline-5- Sodium sulfonate) the concentration of aluminum is 0.0098M;

[0050] 3. Mix solution A and solution B to obtain solution C, and pour solution C into a four-necked flask;

[0051] 4. Dissolve 0.8g NaOH in 40ml to remove CO 2 , deionized water, the NaOH solution was passed through a constant pressure funnel, and under nitrogen protection conditions, slowly added dropwise to the four-necked flask equipped with solution C until the pH value was 11 to obtain slurry D, which was transferred to a 100ml high-pressure The reaction kettle was placed in an oven at 140°C for 36 hours; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com