Coating material and preparation method thereof

A film and substrate technology, applied in the field of preparation of the coating material, can solve the problems of short film formation time, pollution, poor film stability, etc., and achieve excellent wear resistance and corrosion resistance, metal Strong texture and good binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

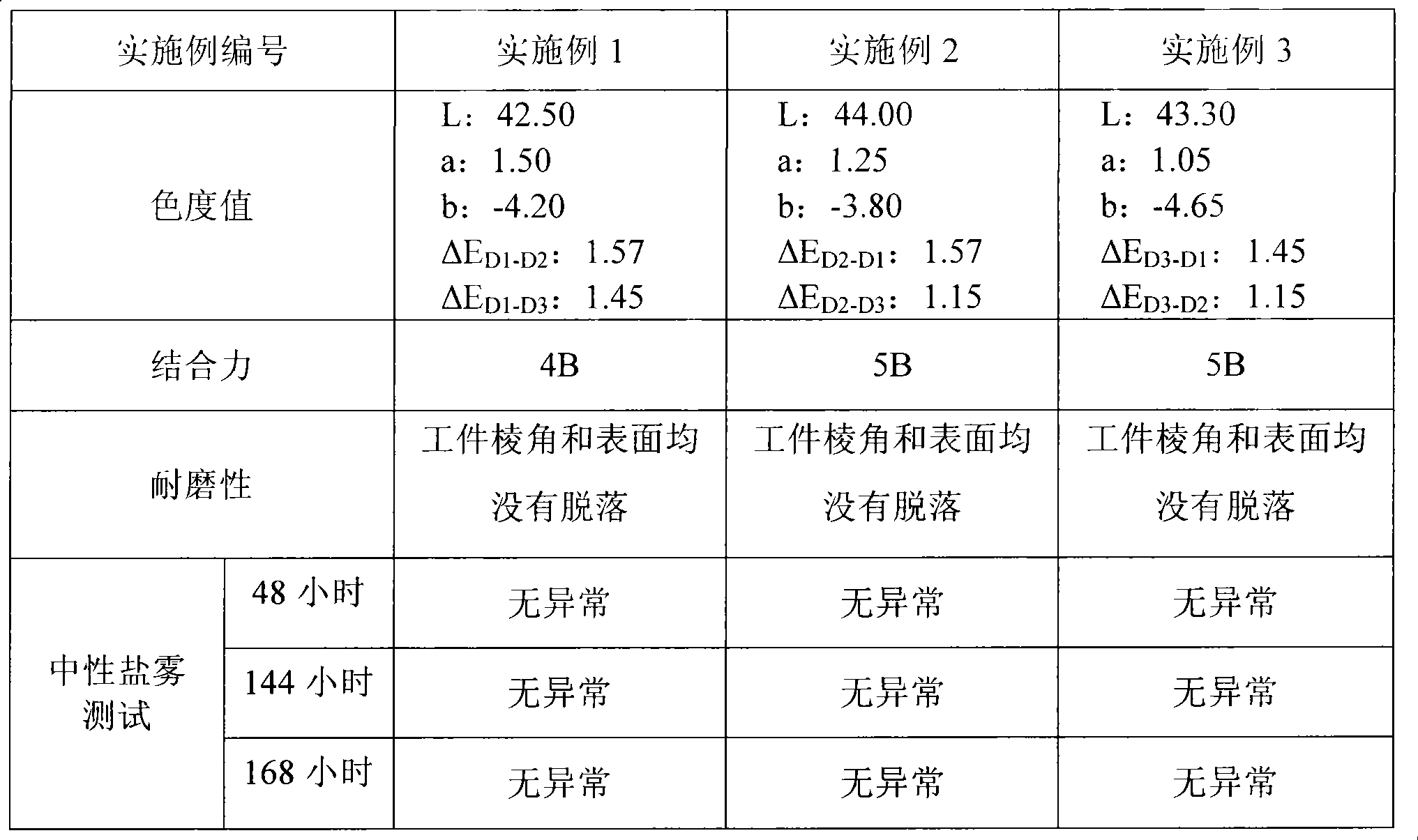

Examples

preparation example Construction

[0013] The preparation method of the coating material provided by the present invention comprises, under the magnetron sputtering condition of forming titanium-zirconium film layer and the magnetron sputtering condition of forming titanium-zirconium carbonitride film layer successively, applying power on the magnetron target to make The target material on the magnetron target is sputtered and deposited on the substrate to form a titanium-zirconium film layer and a titanium-zirconium carbonitride film layer coated on the substrate in sequence, and the target material is titanium-zirconium inlaid target.

[0014] Forming the above film layer is carried out by magnetron sputtering ion plating equipment, preferably using multi-arc-intermediate frequency magnetron sputtering ion plating equipment (BYD-800 type of Shenzhen Zhenhengchang Industrial Co., Ltd.). The multi-arc-intermediate frequency magnetron sputtering ion plating equipment includes a vacuum chamber, a multi-arc source...

Embodiment 1

[0031] This example illustrates the coating material of the present invention and its preparation method.

[0032] The substrate is made of titanium alloy (model TA2)

[0033] 1. Pretreatment

[0034] (1) mechanical polishing

[0035]Use the polishing machine (JM-101 model) produced by Dongguan Jingmi Machinery Equipment Co., Ltd. to use the yellow medium-coarse polishing paste (SBT-600 model) produced by Jiangmen Jielixin Polishing Materials Co., Ltd. to polish the polishing wheel at 2840 rpm Roughly polish the titanium alloy workpiece for 10 minutes at a rotating speed, and then use a white fine polishing paste (SBW-804 model) to perform fine polishing on the workpiece for 10 minutes at a polishing wheel rotating speed of 2840 rpm.

[0036] (2) Ultrasonic cleaning

[0037] The above-mentioned polished workpieces were soaked in dewaxing water at room temperature, degreasing powder solution and deionized water at 70°C in sequence for ultrasonic cleaning. The cleaning time w...

Embodiment 2

[0047] This example illustrates the coating material of the present invention and its preparation method.

[0048] The substrate is made of stainless steel (model 316L)

[0049] 1. Pretreatment

[0050] (1) mechanical polishing

[0051] Use the polishing machine (JM-101 model) produced by Dongguan Jingmi Machinery Equipment Co., Ltd. to use the yellow medium-coarse polishing paste (SBT-600 model) produced by Jiangmen Jielixin Polishing Materials Co., Ltd. to polish the polishing wheel at 2840 rpm The stainless steel workpiece was roughly polished for 10 minutes at a rotating speed, and then finely polished for 10 minutes with a white fine polishing paste (SBW-804 model) at a polishing wheel rotating speed of 2840 rpm.

[0052] (2) drawing

[0053] Use the polishing machine (JM-101 model) produced by Dongguan Jingmi Machinery Equipment Co., Ltd., and use the red fine polishing paste (555-10 model) produced by Shenzhen Hongfang Guanhua Technology Co., Ltd. under the drawing w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com