Intermediate-temperature gold stamping technology adopting double pro-cure manner

A dual-reverse glazing and upward glazing technology, applied in the field of bronzing, can solve the problems that the reverse glazing process cannot reflect the metal texture, the special unit for cold stamping is expensive, and has no strong visual impact, etc., and achieves a strong metal texture and reduces energy. Consumption and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

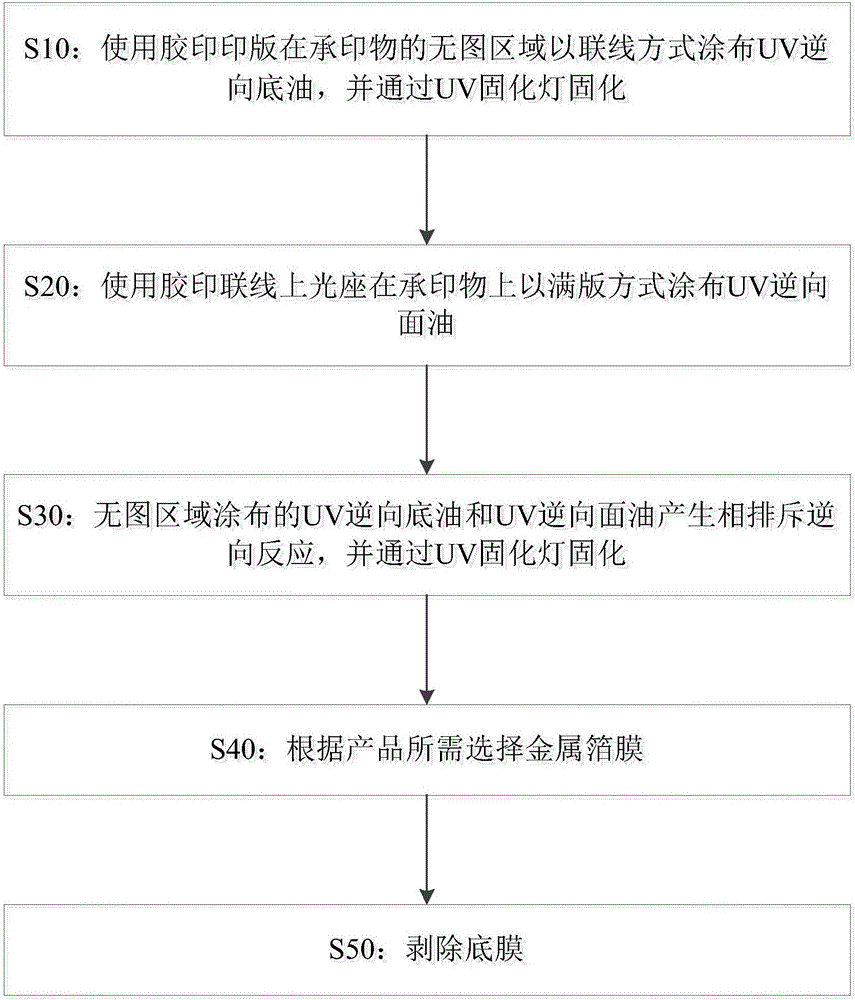

[0030] see figure 1 , which is a process flow diagram of the medium-temperature bronzing process of the double reverse glazing method of the embodiment of the present invention, including the following steps:

[0031] S10: Use an offset printing plate to apply UV reverse primer on the non-image area of the substrate in-line, and cure it with a UV curing lamp;

[0032] Compared with traditional hot stamping, the production cycle of offset printing plate is short and not limited by the etching process of metal printing plate, so that the final product shows a variety of fine line patterns within 0.1-0.2mm.

[0033] S20: Use the offset printing line light seat to apply UV reverse surface oil on the substrate in a full-page manner;

[0034] S30: The UV reverse base coat and UV reverse top coat coated in the non-image area produce a phase repelling reverse reaction, and are cured by a UV curing lamp to obtain a UV curable substrate; in specific application examples, UV is coated...

Embodiment 2

[0041] see figure 1 , which is a process flow diagram of the medium-temperature bronzing process of the double reverse glazing method of the embodiment of the present invention, including the following steps:

[0042] S10: Use an offset printing plate to apply UV reverse primer on the non-image area of the substrate in-line, and cure it with a UV curing lamp;

[0043]Compared with traditional hot stamping, the production cycle of offset printing plate is short and not limited by the etching process of metal printing plate, so that the final product shows a variety of fine line patterns within 0.1-0.2mm.

[0044] S20: Use the offset printing line light seat to apply UV reverse surface oil on the substrate in a full-page manner;

[0045] S30: The UV reverse base coat and UV reverse top coat coated in the non-image area produce a phase repelling reverse reaction, and are cured by a UV curing lamp to obtain a UV curable substrate; in specific application examples, UV is coated ...

Embodiment 3

[0052] see figure 1 , which is a process flow diagram of the medium-temperature bronzing process of the double reverse glazing method of the embodiment of the present invention, including the following steps:

[0053] S10: Use an offset printing plate to apply UV reverse primer on the non-image area of the substrate in-line, and cure it with a UV curing lamp;

[0054] Compared with traditional hot stamping, the production cycle of offset printing plate is short and not limited by the etching process of metal printing plate, so that the final product shows a variety of fine line patterns within 0.1-0.2mm.

[0055] S20: Use the offset printing line light seat to apply UV reverse surface oil on the substrate in a full-page manner;

[0056] S30: The UV reverse base coat and UV reverse top coat coated in the non-image area produce a phase repelling reverse reaction, and are cured by a UV curing lamp to obtain a UV curable substrate; in specific application examples, UV is coated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com