Imitation copper paint and preparation method and construction technology thereof

A construction technology, a technology of imitating copper, applied in the field of paint, can solve the problem that the stability of performance cannot be guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

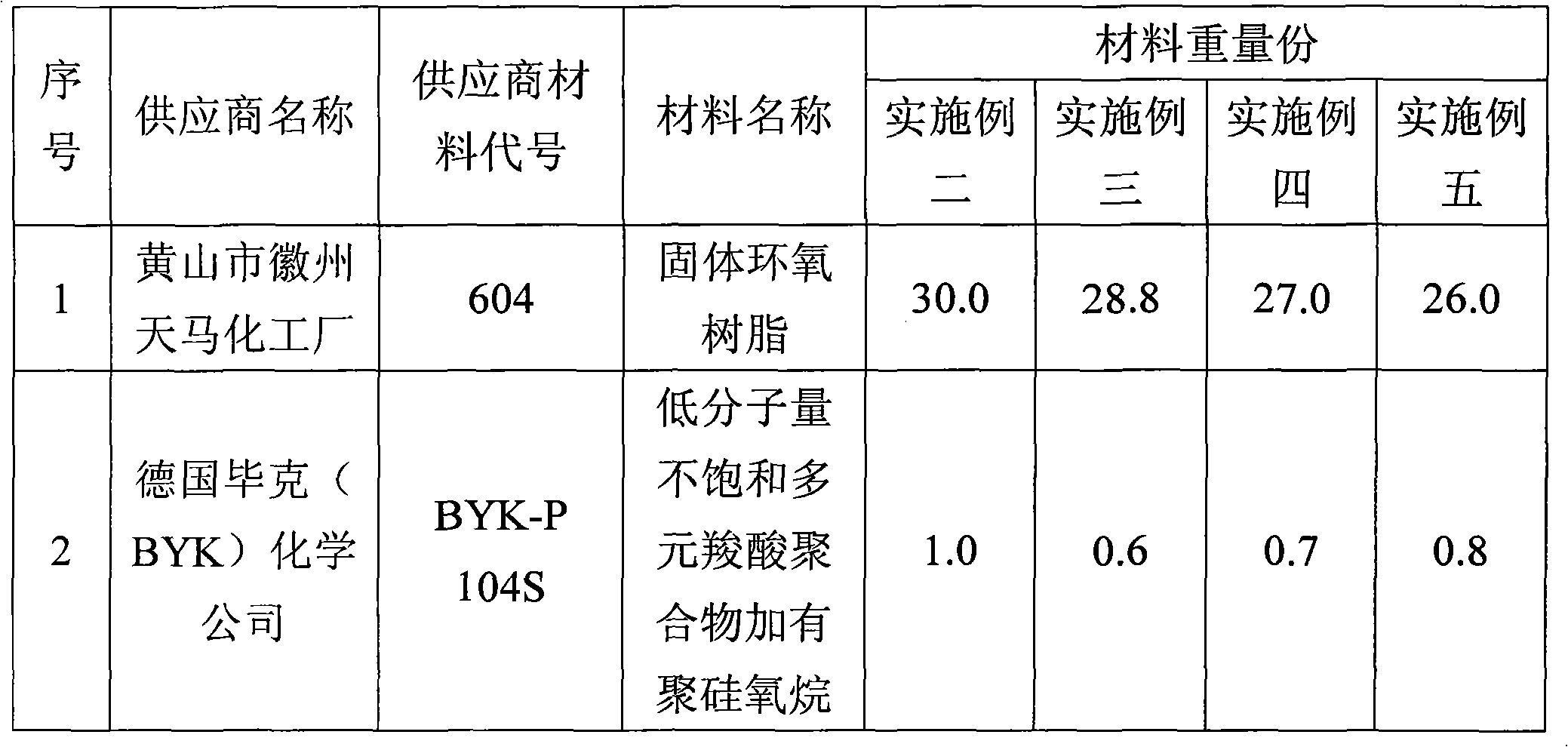

[0057] In embodiment one, the preparation method of epoxy gray primer is as follows:

[0058] 1. Add the raw materials of items 1, 10, 11, and 13 into the production tank according to the weight ratio, disperse them with a disperser at high speed (1200 rpm) for 20 minutes, until the fineness is ≤15 μm, filter with a 200-mesh filter, and pack .

[0059] 2. Dissolve items 2, 3, 4, and 5 in the production tank with the solvents of items 9 and 12, and disperse them for 5 minutes at a low speed (300 rpm) with a disperser, and then add the semi-finished products of the first item, items 6, 7, Put the 8 raw materials into the production tank, disperse them with a disperser at high speed (1200 rpm) for 20 minutes, stop the machine and let it stand for 12h-24h, transfer to a sand mill to grind to a fineness of ≤20μm, filter through a 200-mesh filter, and pack.

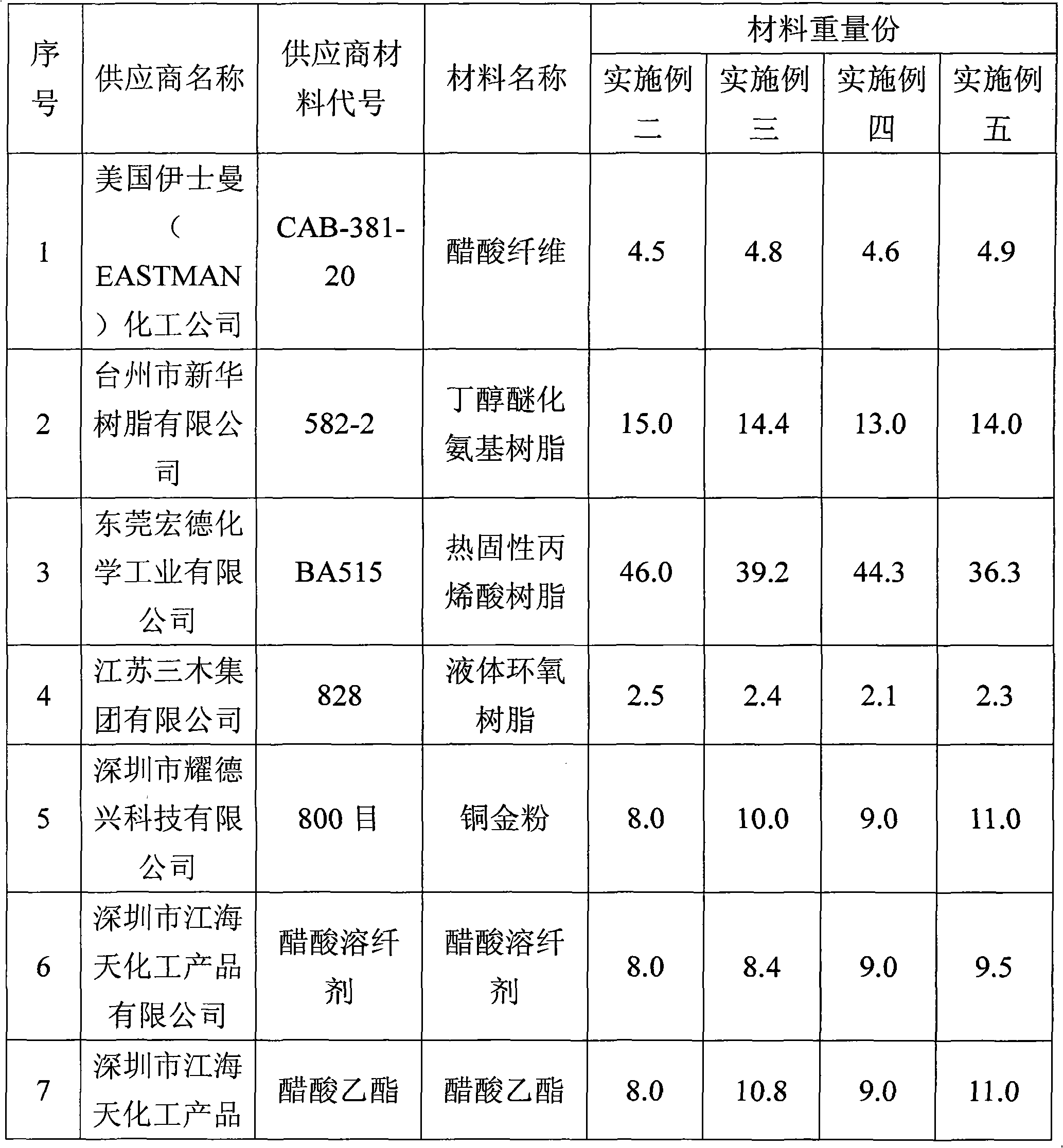

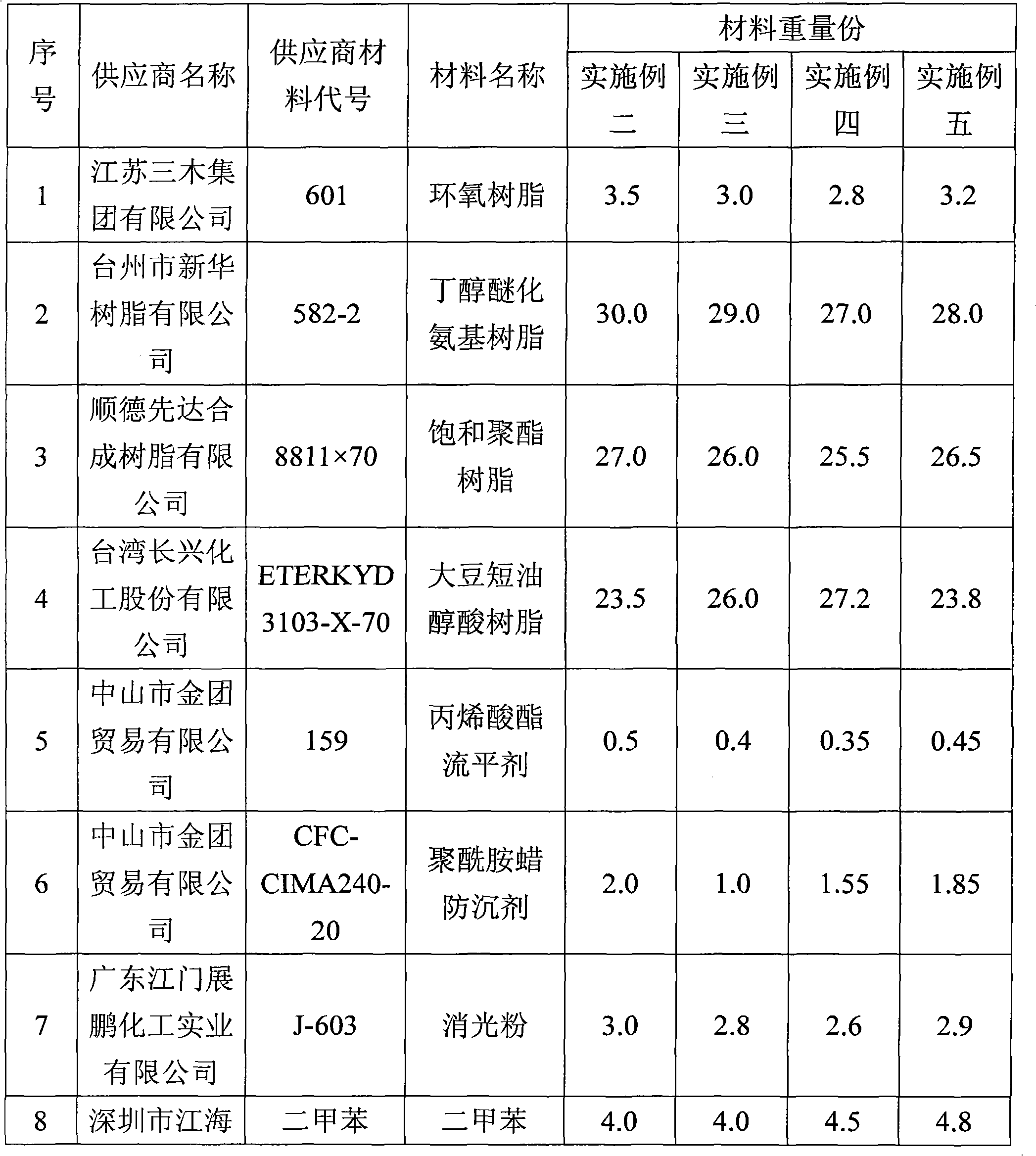

[0060] In embodiment one, the formula of copper powder baking varnish is as shown in table two.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com