Three-dimensional graphene/metal line or metal wire composite structure and preparation method thereof

A composite structure and metal wire technology, applied in the field of nanomaterials, can solve the problems of many structural defects in graphene, and achieve the effects of simple preparation method, excellent corrosion resistance, and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the three-dimensional graphene / metal wire or metal wire composite structure and the graphene tube of the present invention specifically includes the following steps: using the metal wire or metal wire as a catalytic template, putting it into a chemical vapor deposition reaction chamber, introducing hydrogen and protective gas, After heating to a reaction temperature of 400-1200°C, keep the temperature constant for 0-60 minutes, and introduce a carbon source for reaction. During the reaction, the protective gas flow rate is 1-1000 sccm, the hydrogen flow rate is 1-500 sccm, and the gaseous carbon source is 1-200 sccm. The reaction time ranges from 1 minute to 20 hours; during the reaction process, the gas flow rate is maintained, and after the reaction is completed, the cooling rate is controlled at 10-300°C / min, and cooled to room temperature to obtain a three-dimensional graphene / metal wire or metal wire composite structure.

[0028] Further, t...

Embodiment 1

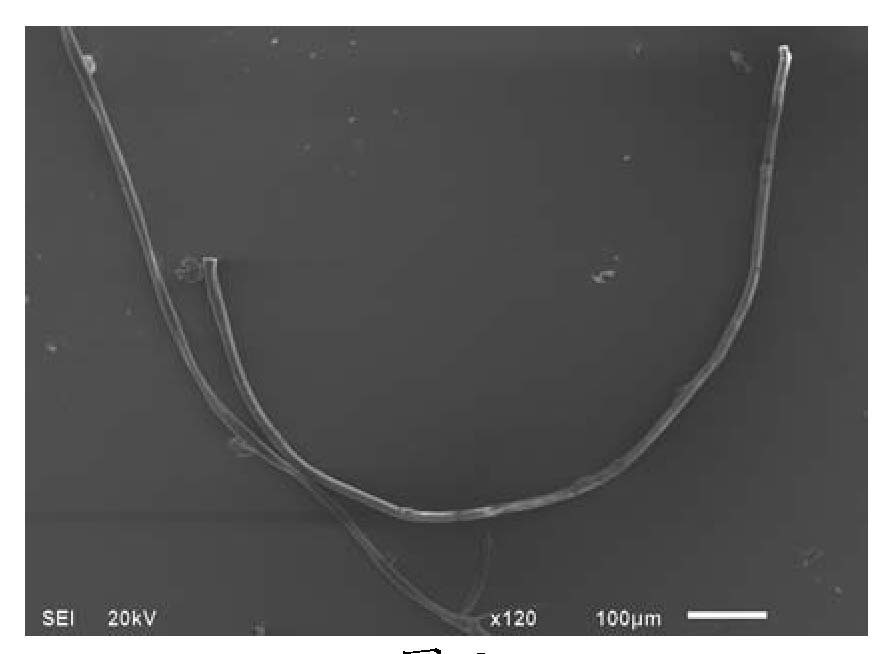

[0044] (1) Nickel wire is used as the catalytic template, and the average diameter of the nickel wire is 25 μm. After ultrasonic cleaning with ethanol, acetone and isopropanol, put the nickel wire into the chemical vapor deposition reaction furnace, pass through 100sccm hydrogen and 100sccm argon, start heating to 1000°C after 60 minutes, and pass 5sccm methane after 30 minutes at constant temperature, and react Time 30min, stop feeding methane after the reaction is over, turn off the electric furnace, cool to room temperature rapidly, obtain graphene / nickel wire composite structure, scanning electron microscope photo is as follows figure 1 shown.

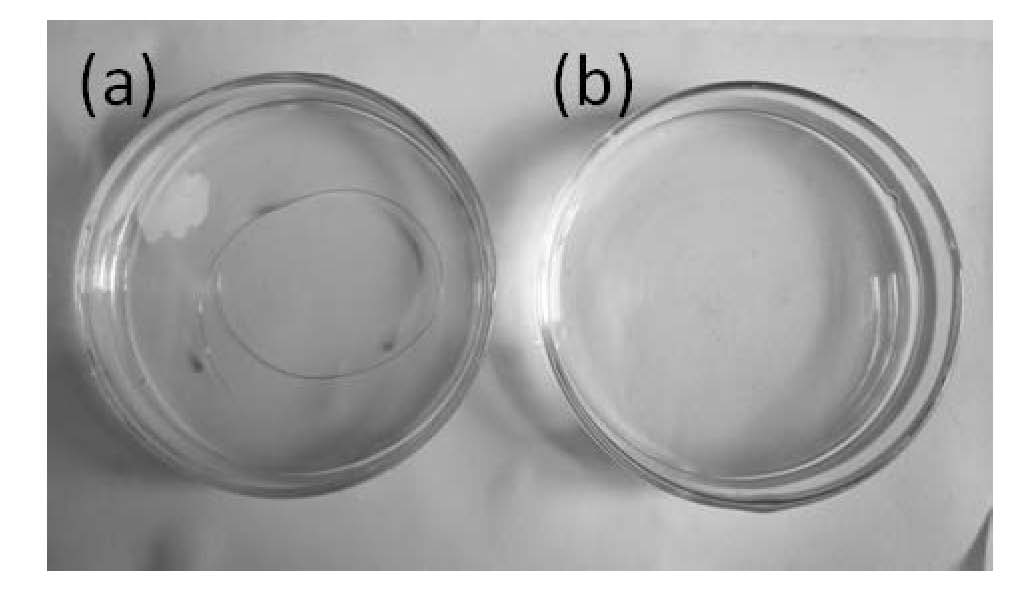

[0045] (2) Place the product prepared in step (1) in an acetone solution of 4wt% polymethyl methacrylate, take it out and dry it at 100°C for 3 hours to deposit a layer of polymethyl methacrylate on its surface, and put 100ml of In 5M nitric acid solution for 4h, remove the nickel wire, and then put it into the acetone solution to...

Embodiment 2

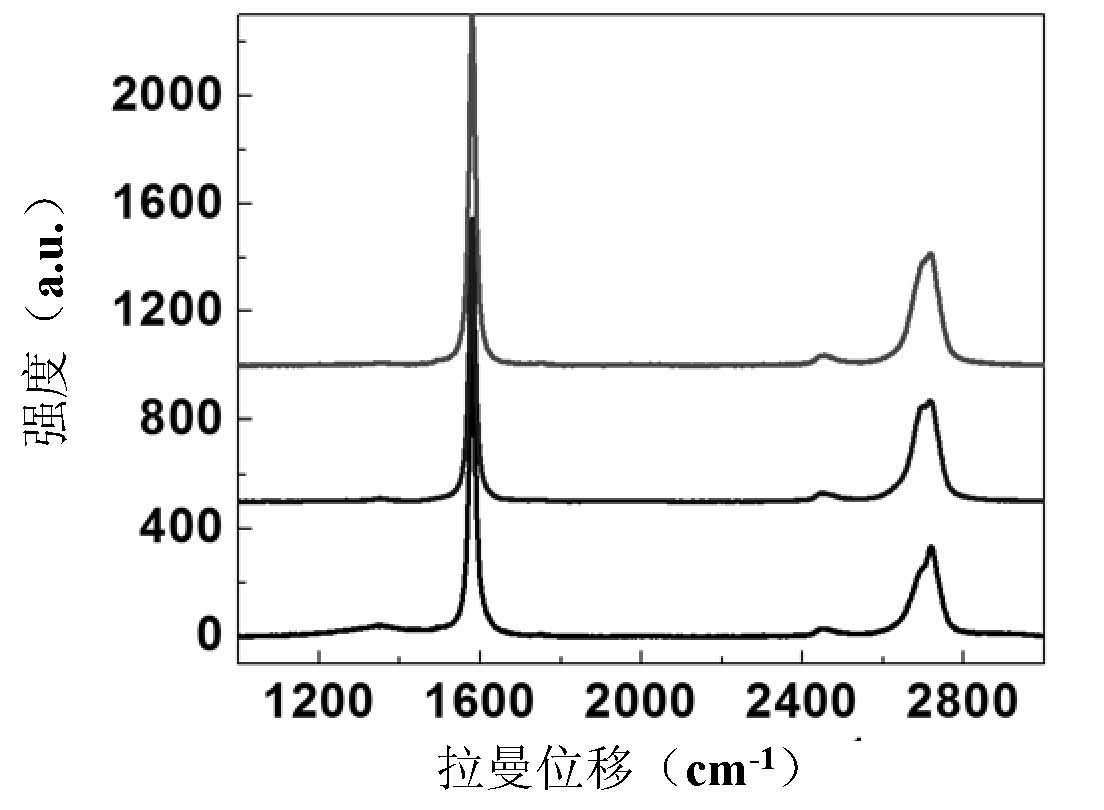

[0047] The preparation method is basically the same as in Example 1, except that in step (1), a nickel wire with a diameter of 100 μm is used as a catalytic template to obtain a three-dimensional graphene tube with 10-20 layers, and the graphene structure is complete and free of defects.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com