Graphene foam with three dimensional fully connected network and macroscopic quantity preparation method thereof

A fully connected network and graphene foam technology, which is applied in the field of graphene-based new materials and its chemical vapor deposition preparation, can solve the problem of low graphene production, achieve high specific surface area, high porosity, excellent charge conduction and heat conduction effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

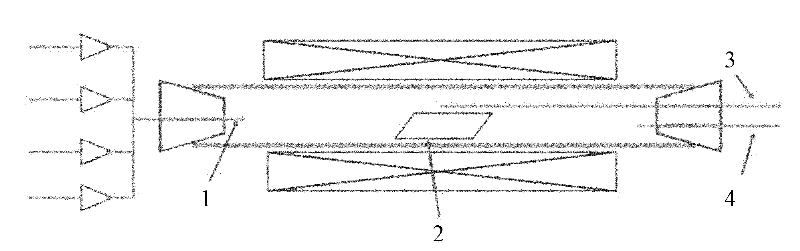

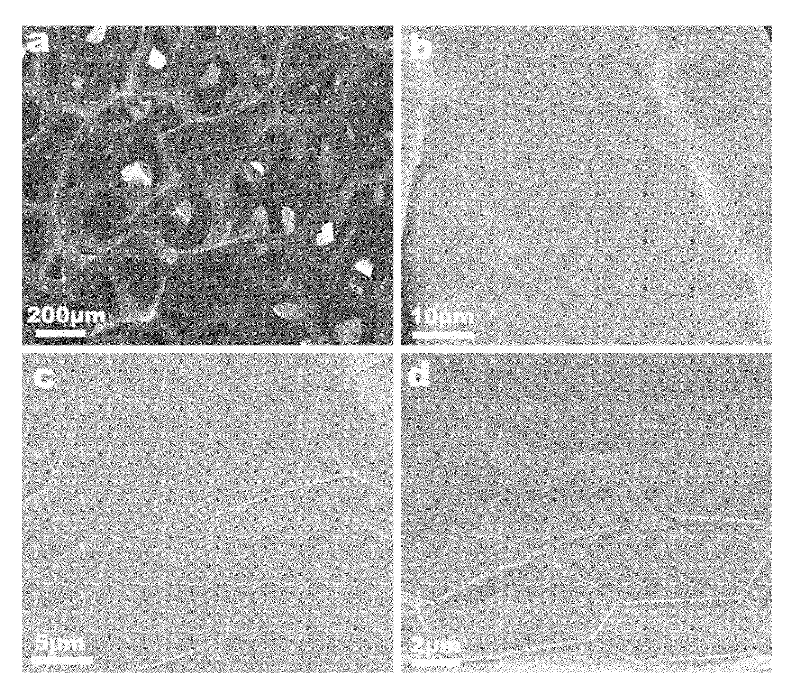

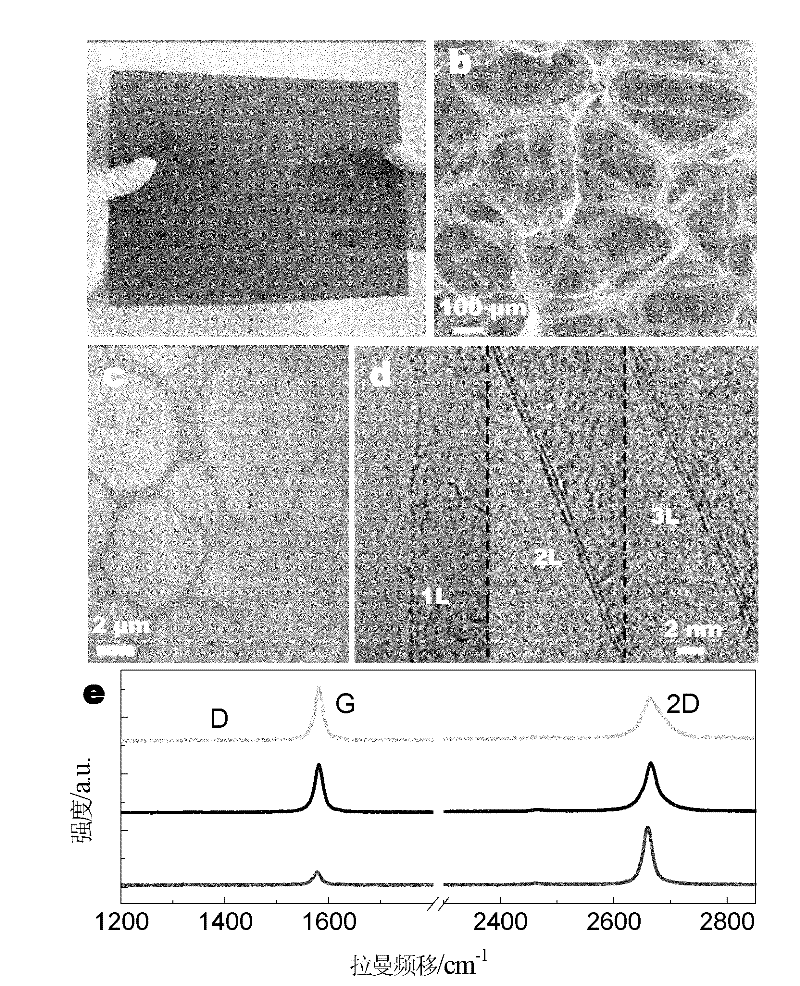

[0032] First, if figure 1 As shown, the present invention adopts the horizontal reaction furnace to grow graphene, the two ends of the horizontal reaction furnace are respectively provided with a gas inlet 1 and a gas outlet 4, the foamed nickel 2 is placed in the high temperature zone of the horizontal reaction furnace, and the thermocouple 3 is located in the horizontal reaction furnace. Furnace high temperature zone to monitor the reaction temperature in real time. Nickel foam (70 mm × 300 mm × 1.2 mm, the pore size distribution is about 110PPI, the surface density is about 300g / m 2) placed in the central area of a horizontal reaction furnace (the diameter of the furnace tube is 75mm, and the length of the reaction zone is 300mm) (the reaction zone, where there are thermocouples to monitor the furnace temperature in real time); heated to 1000°C in an atmosphere of hydrogen and argon (Hydrogen and argon flow rates are 200 and 500 ml / min respectively during the heating pro...

Embodiment 2

[0036] First, if figure 1 As shown, the present invention adopts the horizontal reaction furnace to grow graphene, the two ends of the horizontal reaction furnace are respectively provided with a gas inlet 1 and a gas outlet 4, the foamed nickel 2 is placed in the high temperature zone of the horizontal reaction furnace, and the thermocouple 3 is located in the horizontal reaction furnace. Furnace high temperature zone to monitor the reaction temperature in real time. Nickel foam (70 mm × 300 mm × 1.2 mm, the pore size distribution is about 110PPI, the surface density is about 300g / m 2 ) placed in the central area of a horizontal reaction furnace (the diameter of the furnace tube is 75mm, and the length of the reaction zone is 300mm) (the reaction zone, where there are thermocouples to monitor the furnace temperature in real time); heated to 1000°C in an atmosphere of hydrogen and argon (Hydrogen and argon flow rates are 200 and 500 ml / min respectively during the heating pr...

Embodiment 3

[0040] First, if figure 1 As shown, the present invention adopts the horizontal reaction furnace to grow graphene, the two ends of the horizontal reaction furnace are respectively provided with a gas inlet 1 and a gas outlet 4, the foamed nickel 2 is placed in the high temperature zone of the horizontal reaction furnace, and the thermocouple 3 is located in the horizontal reaction furnace. Furnace high temperature zone to monitor the reaction temperature in real time. Nickel foam (70 mm × 300 mm × 1.2 mm, the pore size distribution is about 110PPI, the surface density is about 300g / m 2 ) placed in the central area of a horizontal reaction furnace (the diameter of the furnace tube is 75mm, and the length of the reaction zone is 300mm) (the reaction zone, where there are thermocouples to monitor the furnace temperature in real time); heated to 900°C in an atmosphere of hydrogen and argon (The flow rate of hydrogen and argon during the heating process is 200 and 500 ml / min res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com