Preparation method of pod-shaped carbon nanotube encapsulation non-noble metal nano-particles

A carbon nanotube and non-precious metal technology, which is applied in the field of preparation of pod-shaped carbon nanotube-encapsulated non-precious metal nanoparticle, can solve the problem of nanoparticle instability, difficulty in preparing dispersed non-precious metal nanoparticle, easy to be oxidized and agglomerated and other problems, to achieve the effect of simple method, easy to scale up production and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Seal 3.0 g of sodium azide and 3.0 g of ferrocene into a 40 mL autoclave under nitrogen protection.

[0030] 2. Keep the autoclave in (1) at 350° C. for 4 hours.

[0031] 3. Treat the sample obtained in (2) with 18% (mass concentration) hydrochloric acid solution for 5 hours. Then wash with water and ethanol several times and filter.

[0032] 4. Dry the sample obtained in (3) at 120° C. for 12 hours to obtain the pod iron nanomaterial.

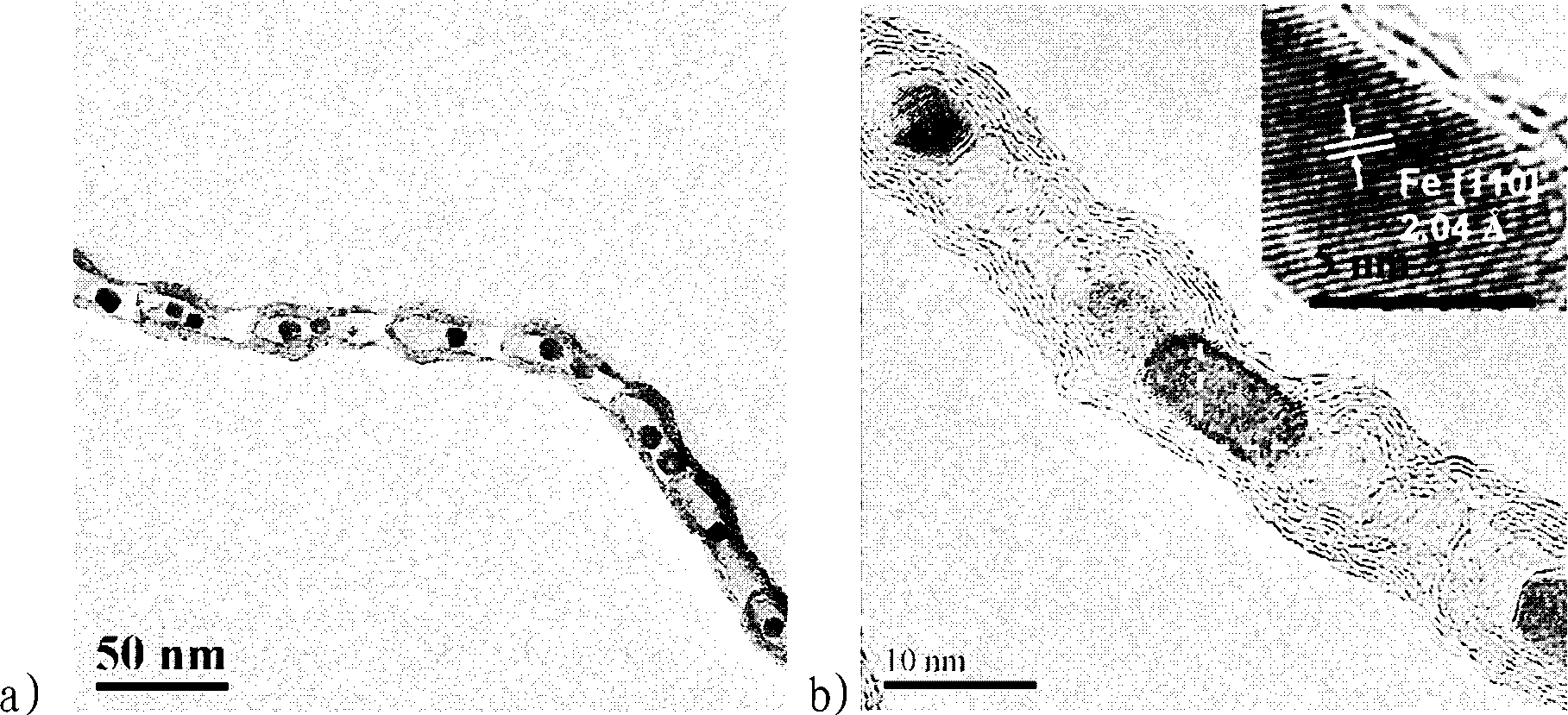

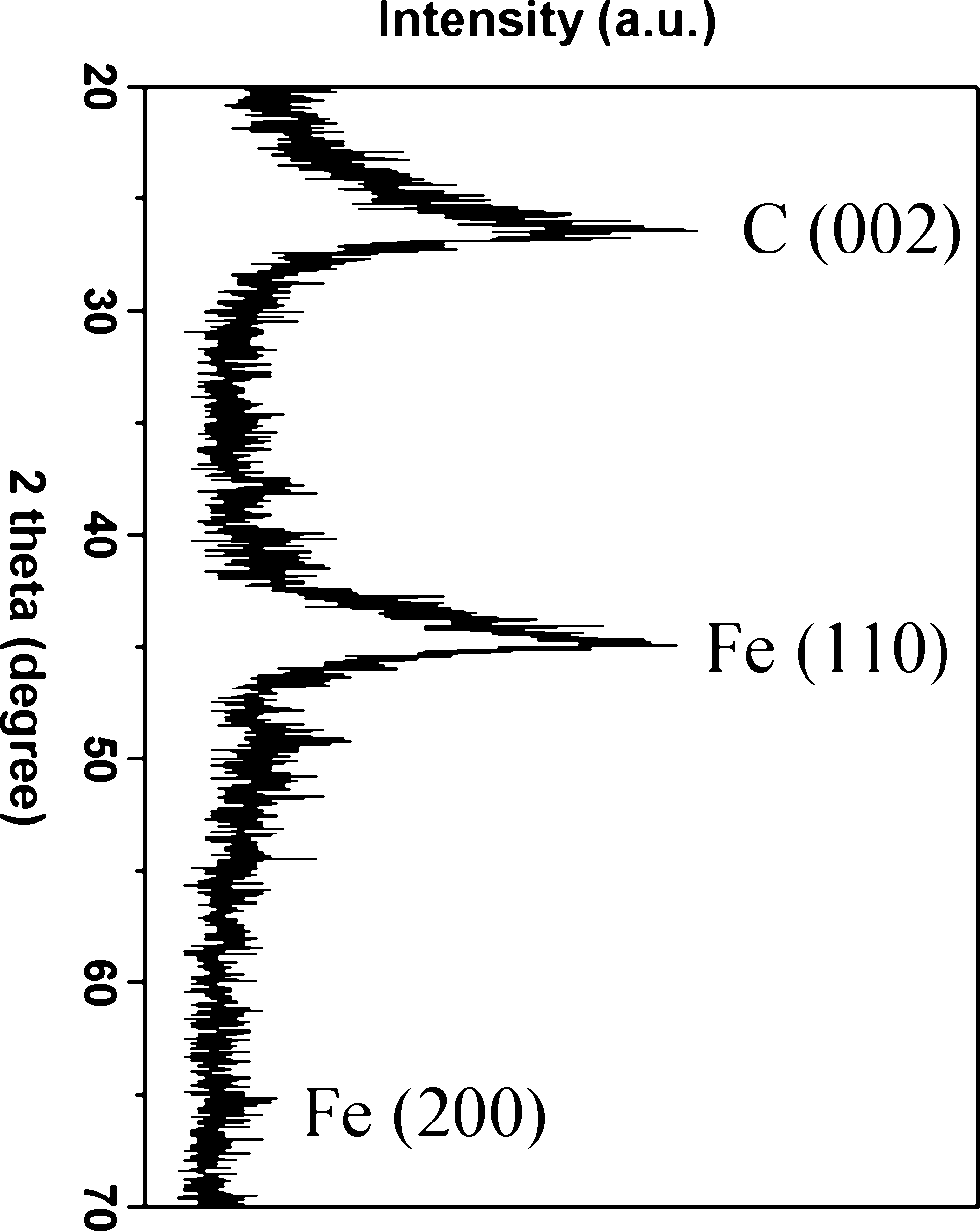

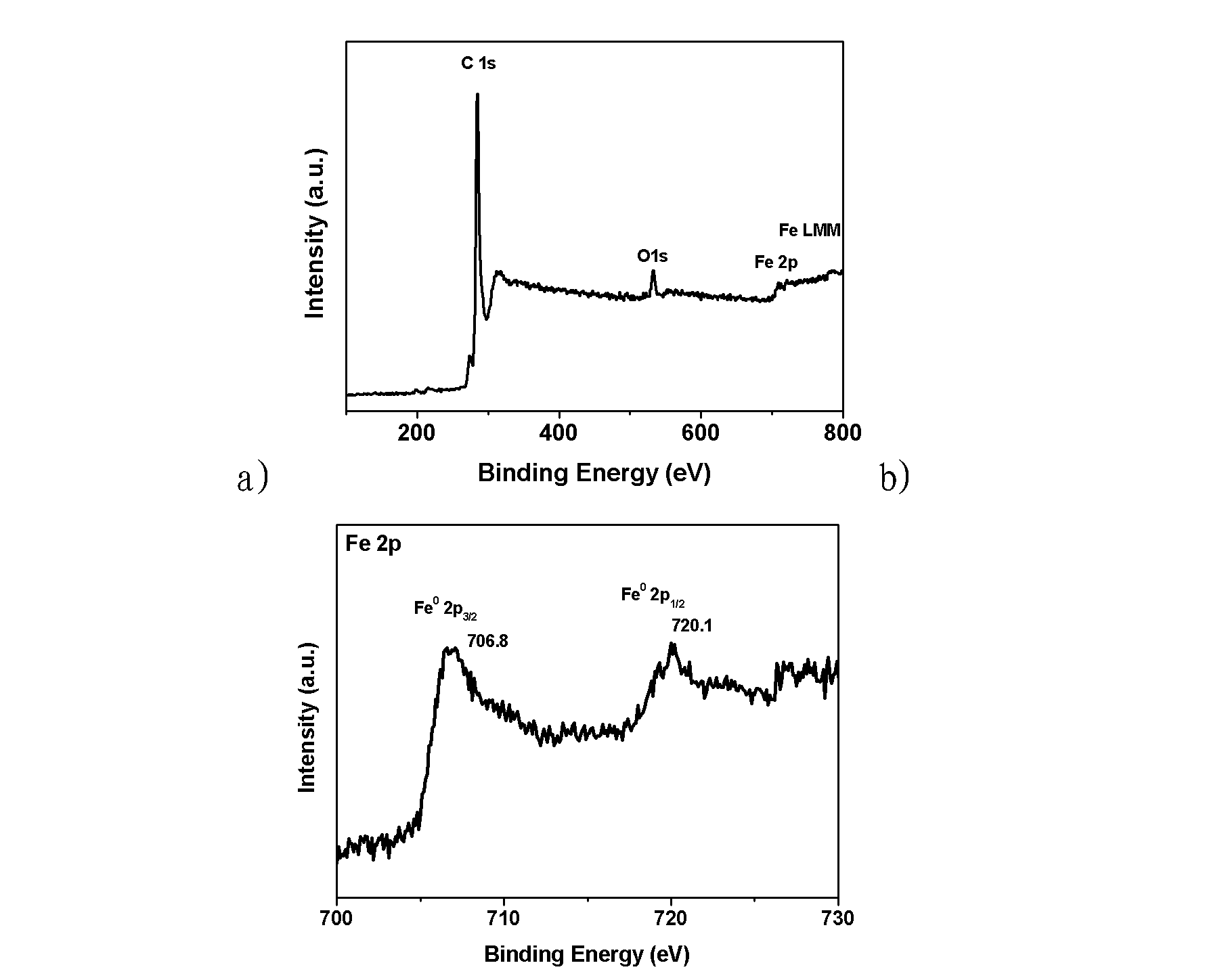

[0033] One reaction can obtain 1.4 grams of pure pod iron nanomaterials. TEM (see figure 1 ), X-ray diffraction spectrum (see figure 2 ) and X-ray photoelectron spectroscopy (see image 3 ) shows that the obtained sample has a pod-like structure, and the encapsulated iron nanoparticles are elemental.

Embodiment 2

[0035] 1. Seal 1.0g of lithium nitride and 3.0g of ferrocene into a 40mL autoclave under nitrogen protection.

[0036] 2. Keep the autoclave in (1) at 450° C. for 6 hours.

[0037] 3. Same as step 3 of embodiment 1.

[0038] 4. Same as step 4 of embodiment 1.

[0039] One reaction can obtain 1.1 grams of pure pod iron nanomaterials. Analytical tests (transmission electron microscope, X-ray diffraction spectrum and X-ray photoelectron spectrum) show that the obtained sample has a pod-like structure, and the encapsulated iron nanoparticles are in a single state.

Embodiment 3

[0041] 1. Seal 2.0g of sodium and 3.5g of cobaltocene into a 40mL autoclave under argon protection.

[0042] 2. Keep the autoclave in (1) at 250° C. for 10 hours.

[0043] 3. Same as step 3 of embodiment 1.

[0044] 4. Same as step 4 of embodiment 1.

[0045] One reaction can obtain 1.6 grams of pure pod iron nanomaterials. Analytical tests (transmission electron microscope, X-ray diffraction spectrum and X-ray photoelectron spectrum) show that the obtained sample has a pod-like structure, and the encapsulated cobalt nanoparticles are in a simple state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com