Preparation method for graphene material with porous structure

A porous structure, graphene technology, applied in the direction of graphene, nano-carbon, nanotechnology, etc., can solve the problems of poor quality of graphene, hindering the rapid transmission of electrons, unfavorable rapid electron transmission, etc., to achieve easy process, reduce interface resistance, The effect of excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The invention relates to a preparation method for preparing a graphene material with a porous structure, which is mainly used for reducing the graphene interface resistance and improving its electrical conductivity. Its technical feature is that: the porous structure material is used as a template, and the highly conductive porous structure graphene is obtained through chemical vapor deposition. The template used in the present invention adopts magnesium oxide / silicon composite material with a porous structure, and is prepared in a large amount by a chemical vapor deposition method. The preparation method of the porous structure graphene material has simple process, easy control of the process, and excellent electrical conductivity of the material.

[0019] As an example, the preparation method of the porous structure graphene material of the present invention is specifically described below.

[0020] The preparation process of porous structure graphene material of the...

Embodiment 1

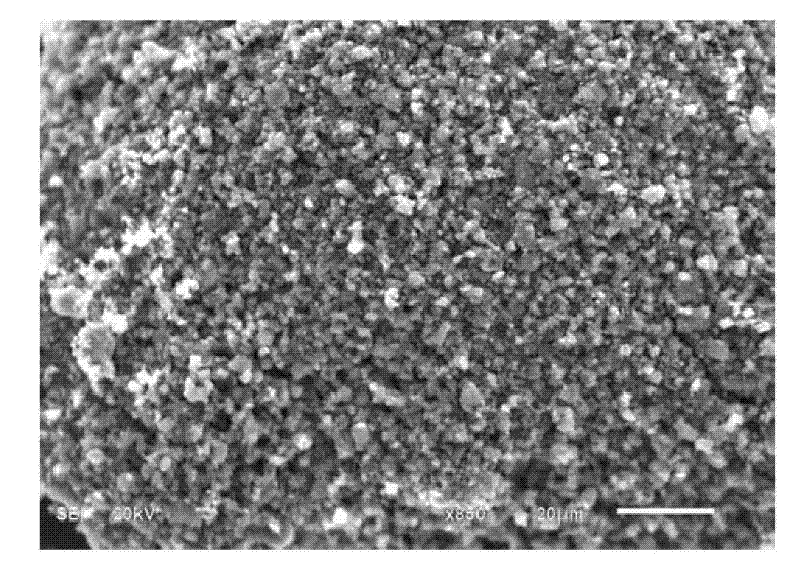

[0028] (1) Using metal magnesium powder and silicon dioxide powder as raw materials, according to the molar ratio of magnesium and silicon dioxide 2:1, after the raw materials are mixed and ball milled for 15 hours, the air in the reaction furnace chamber is purged with a mixed gas of hydrogen and argon. Completely expelled, heat treatment at 600°C for 8h, to obtain a porous magnesium oxide / silicon composite material, the scanning electron microscope photo of the product is as follows figure 1 shown;

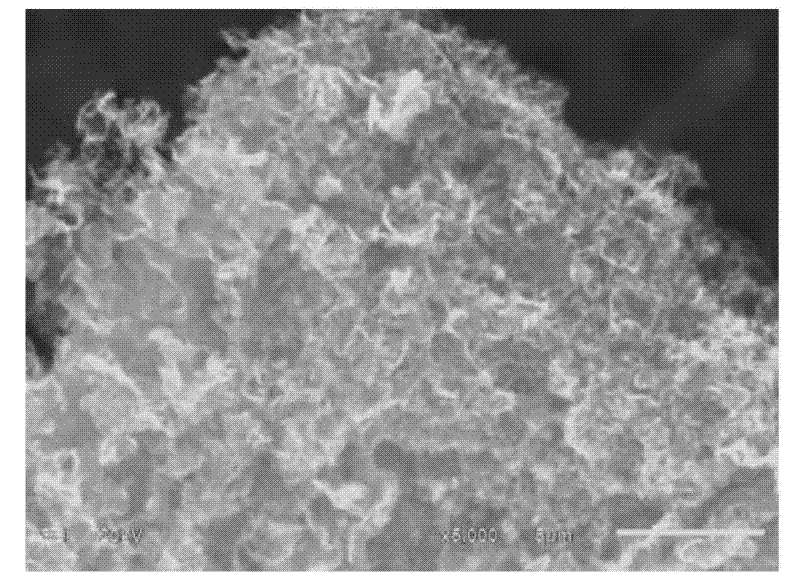

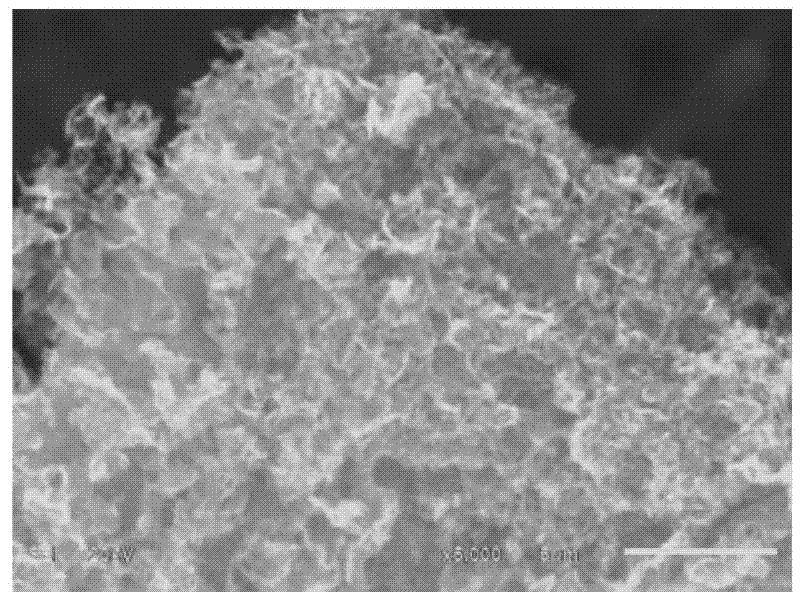

[0029] (2) Using the above-mentioned porous magnesium oxide / silicon composite material as a template, put it into a quartz boat, put it into the central area of the chemical vapor deposition reaction furnace, feed 20SCCM hydrogen and 200SCCM argon, and start heating to 900°C after 60min. After constant temperature for 30 minutes, 20SCCM acetylene was introduced, and the reaction time was 20 minutes. After the reaction, stop passing acetylene, turn off the electric furnace, and...

Embodiment 2

[0032] (1) Using metal magnesium powder and silicon dioxide powder as raw materials, according to the molar ratio of magnesium and silicon dioxide 2:1, after the raw materials are mixed and ball milled for 15 hours, the air in the reaction furnace chamber is purged with a mixed gas of hydrogen and argon. Completely expelled, heat treatment at 700 ° C for 4 hours, to obtain a porous magnesium oxide / silicon composite material, the product scanning electron microscope photo is as follows figure 1 shown;

[0033] (2) Using the above-mentioned porous magnesium oxide / silicon composite material as a template, put it into a quartz boat, put it into the central area of the chemical vapor deposition reaction furnace, feed 20SCCM hydrogen and 200SCCM argon, and start heating to 800°C after 60min. After constant temperature for 30 minutes, 40 SCCM acetylene was introduced, and the reaction time was 20 minutes. After the reaction, stop feeding acetylene, turn off the electric furnace, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sheet resistance | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com