Fast ion conductor modified lithium ion battery cathode material lithium cobalt oxide with fast ion conductor and preparation method

A lithium-ion battery and ion conductor technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve problems that cannot meet commercial applications, achieve the effects of improving overcharge performance and safety performance, avoiding direct contact, and increasing battery capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

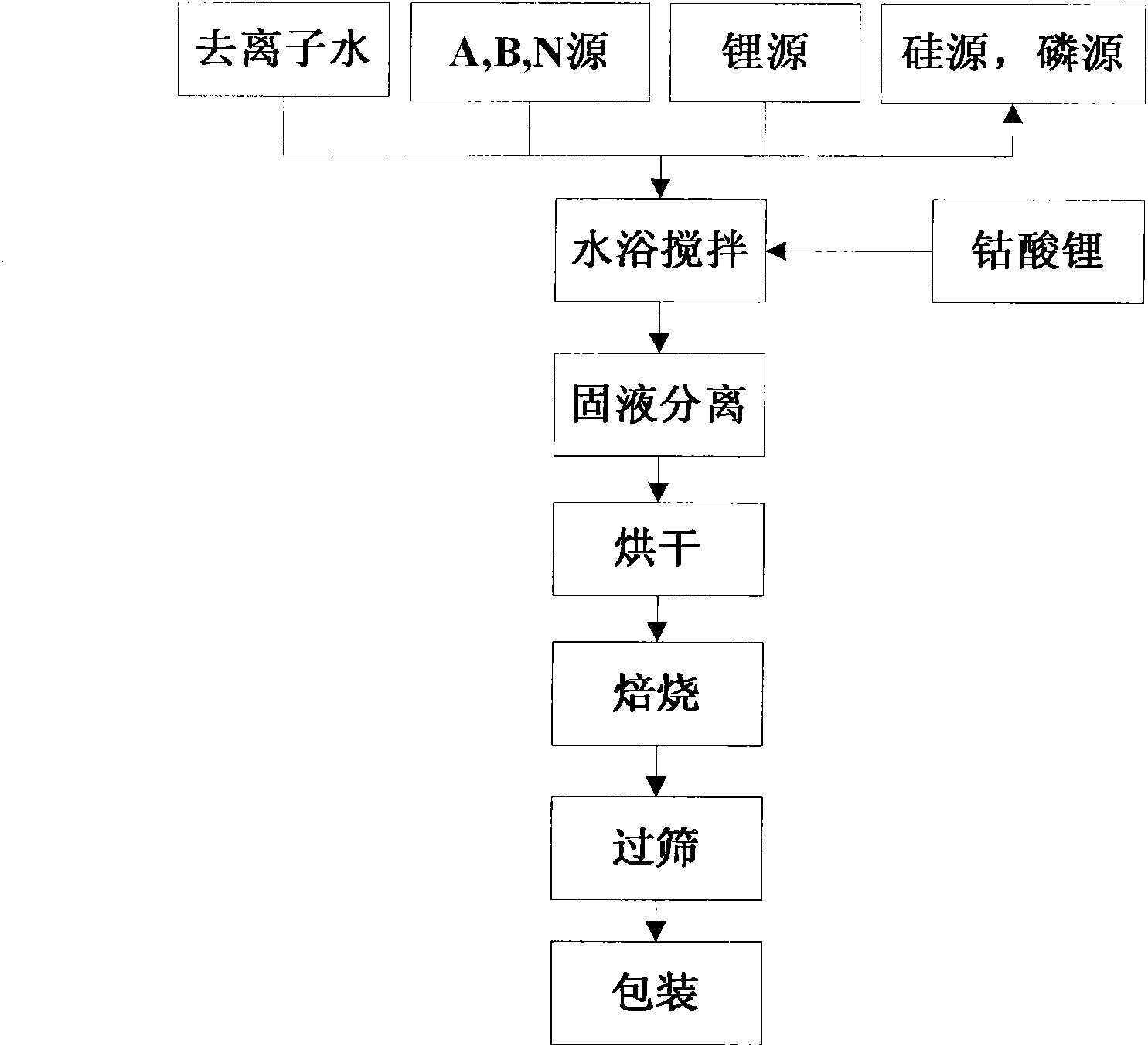

Method used

Image

Examples

Embodiment 1

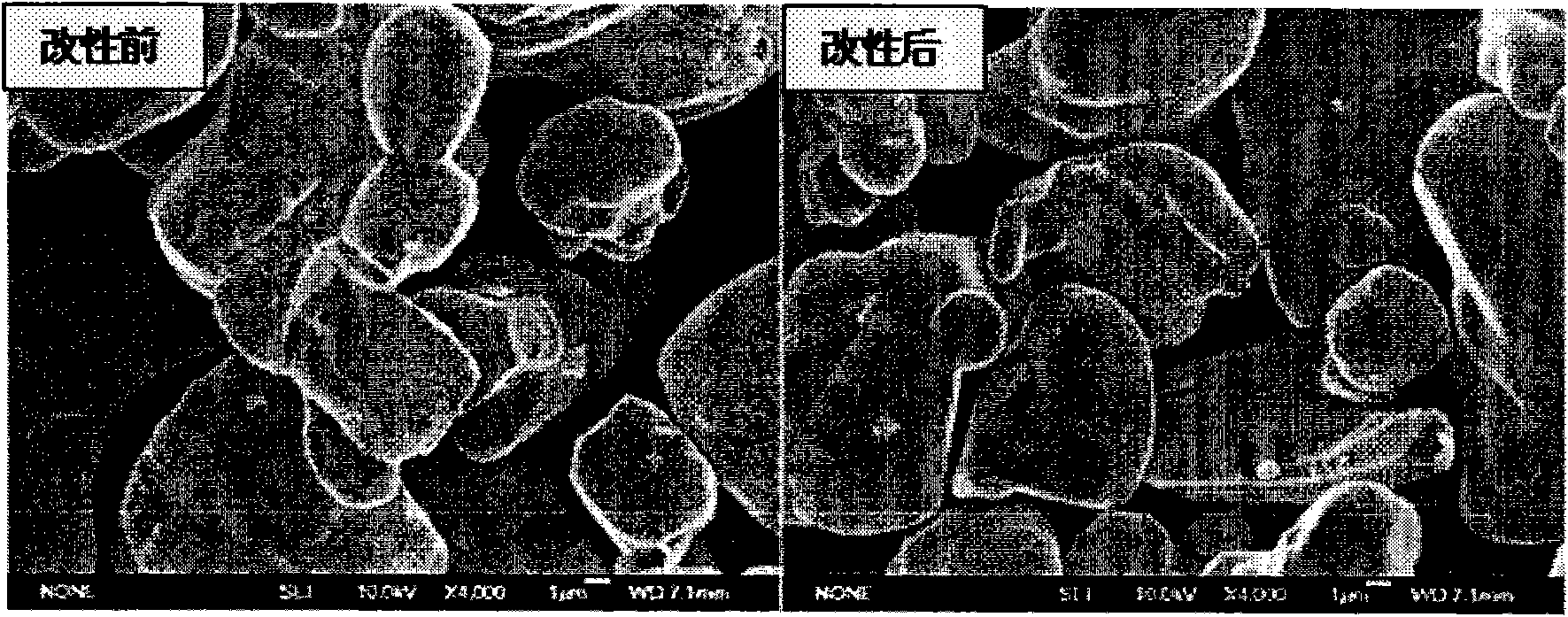

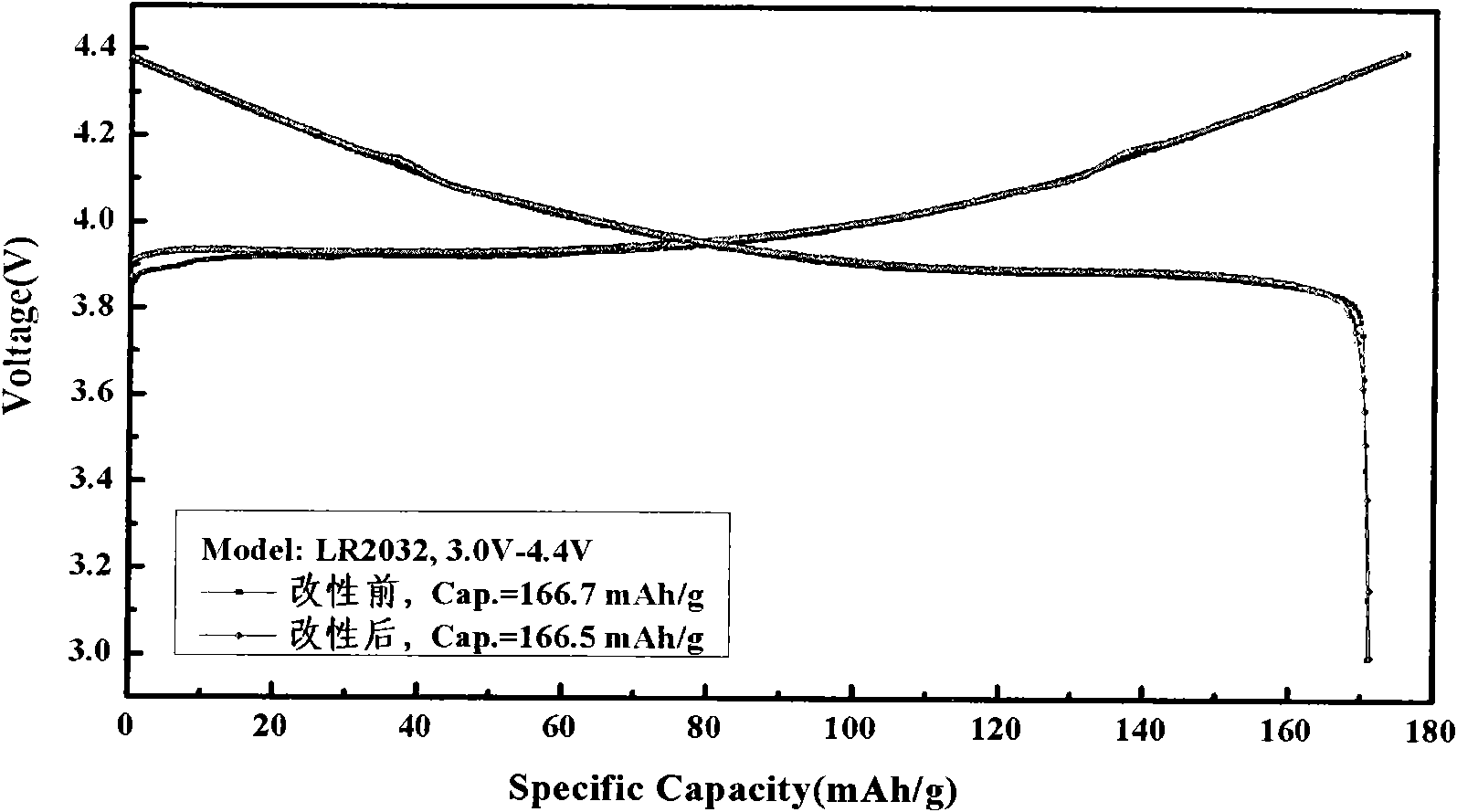

[0043] Weigh 0.2003g of lithium carbonate, 2.7115g of aluminum nitrate and 1.2472g of ammonium dihydrogen phosphate, put the three in a 400ml beaker and stir evenly in a water bath, the temperature of the water bath is 80°C, the stirring speed is 80Hz, and the pH value is adjusted to 8.5 by adding ammonia water dropwise. Weigh 100g of lithium cobaltate, add it into a beaker and continue to stir, impregnate, evaporate to dryness and dry at 150°C for 24h. The obtained powder is roasted in a bell-type furnace, and the roasting system is: 10°C / min to 700°C, heat preservation for 10h, and cool down with the furnace. Through physical and chemical analysis, it is concluded that the surface of the raw material lithium cobaltate is coated with a fast ion conductor layer with an average thickness of about 50nm, and its molecular expression is: Li 3 al 2 P 3 o 12 , the total coating amount is: 1.3% (mass fraction), and the electron microscope photos of the sample show that the microsc...

Embodiment 2

[0047] Weigh 0.7015g, 4.3765g, 0.1159g and 1.9969g of lithium hydroxide, n-butyl titanate, silicon dioxide and ammonium dihydrogen phosphate respectively, put the four in a 100ml beaker and stir evenly in a water bath, the temperature of the water bath is 80°C, The stirring speed was 100 Hz, and ammonia water was added dropwise to adjust the pH value to 9.0. Weigh 150g of lithium cobaltate, add it into a beaker and continue stirring for 2h, filter with suction, and dry the filter cake at 120°C for 24h. The obtained powder is roasted in a bell-type furnace, and the roasting system is as follows: 5°C / min to 900°C, heat preservation for 5h, and cooling with the furnace. Through physical and chemical analysis, it is concluded that the surface of the raw material lithium cobaltate is coated with a fast ion conductor layer with an average thickness of about 120nm, and its molecular expression is: Li 1.3 Ti 2 Si 0.3 P 2.7 o 12 , the total coating amount is: 3.0% (mass fraction),...

Embodiment 3

[0049] Weigh 0.2297g, 0.0098g and 1.7890g of aluminum chloride, n-butyl titanate and lithium dihydrogen phosphate respectively, put the three in a 700ml beaker and stir evenly in a water bath, the temperature of the water bath is 60°C, the stirring speed is 100Hz, and ammonia water is added dropwise Adjust the pH value to 10.0. Weigh 100g of lithium manganate, add it into a beaker and continue stirring for 4h, filter with suction, and dry the filter cake at 120°C for 36h. The obtained powder is roasted in a bell-type furnace, and the roasting system is as follows: 3°C / min to 600°C, heat preservation for 8h, and cooling with the furnace. Through physical and chemical analysis, it is concluded that the surface of the raw material lithium manganate is coated with a fast ion conductor layer with an average thickness of about 100nm, and its molecular expression is: LiTi 2 P 3 o 12 -Li 2 O, the total coating amount is: 1.9% (mass fraction), the modified material is packed into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com