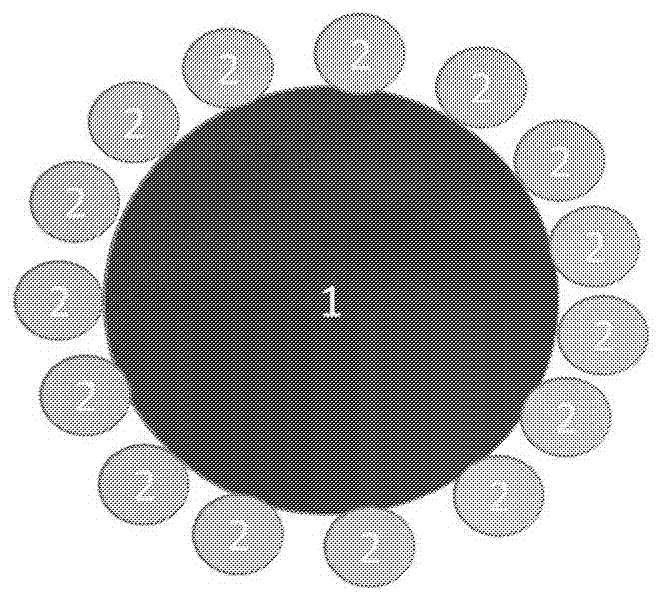

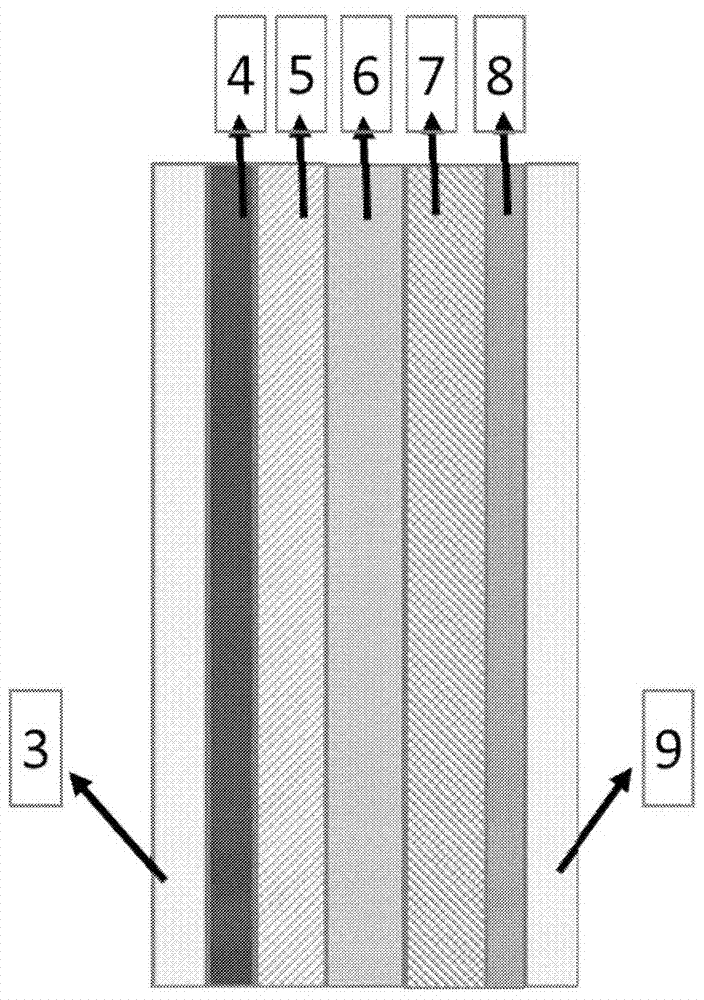

Composite electrode material of solid-state lithium battery and preparation method thereof

A technology of composite electrodes and solid electrolytes, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low lithium ion conductivity and high internal resistance, and achieve the effects of increasing conduction rate, reducing interface resistance, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The positive electrode is lithium cobalt oxide, the negative electrode is lithium titanate, and the solid electrolyte is Li 7 La 2 Zr 2 o 12 . Weigh 0.0882g of Li according to the coating weight ratio of 15:85 7 La 2 Zr 2 o 12 Powder, 0.5g of lithium cobaltate powder. The above powders were manually mixed in a mortar, then transferred to a zirconia ball mill jar, equipped with an appropriate amount of zirconia balls, and ball milled at a speed of 400r / min. After 12 hours of ball milling, the mixed powder was taken out. Transfer the mixed powder into a zirconia crucible, put the crucible into a muffle furnace, and sinter at 1125°C with a heating rate of 5°C / min and a sintering time of 6 hours. After sintering, a composite positive electrode material is obtained.

[0055] Similarly, weigh 0.0882g of Li according to the coating weight ratio of 15:85 7 La 2 Zr 2 o 12 powder and 0.5 g of lithium titanate powder, and repeat the above method to obtain a composite ...

Embodiment 2

[0059] Lithium cobaltate is used for the positive electrode, graphite is used for the negative electrode, and Li 7 La 2 Zr 2 o 12 . According to the coating weight ratio of 15:85, three raw materials Li with a total molar ratio of 3.5:1:1 were weighed with a total amount of 0.0882g. 2 CO 3 , La 2 o 3 , ZrO 2 as Li 7 La 2 Zr 2 o 12 Precursor powder, and 0.5g of lithium cobalt oxide powder. The above powders were manually mixed in a mortar, then transferred to a zirconia ball mill jar, equipped with an appropriate amount of zirconia balls, and ball milled at a speed of 400r / min. After 12 hours of ball milling, the mixed powder was taken out. Transfer the mixed powder into a zirconia crucible, put the crucible into a muffle furnace, and sinter at 1125°C with a heating rate of 5°C / min and a sintering time of 6 hours. After sintering, a composite positive electrode material is obtained.

[0060] Similarly, weigh 0.0882g of Li according to the coating weight ratio of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com