In-situ gasification mining method of extremely thin coal seam group based on microwave radiation

An ultra-thin coal seam, microwave radiation technology, used in coal gasification, mining fluids, earthwork drilling and other directions, can solve the problems of slow coal body heating rate, difficult coal gasification, low coal body permeability, etc., to achieve convenient operation, The effect of improving coal gasification efficiency and increasing conduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

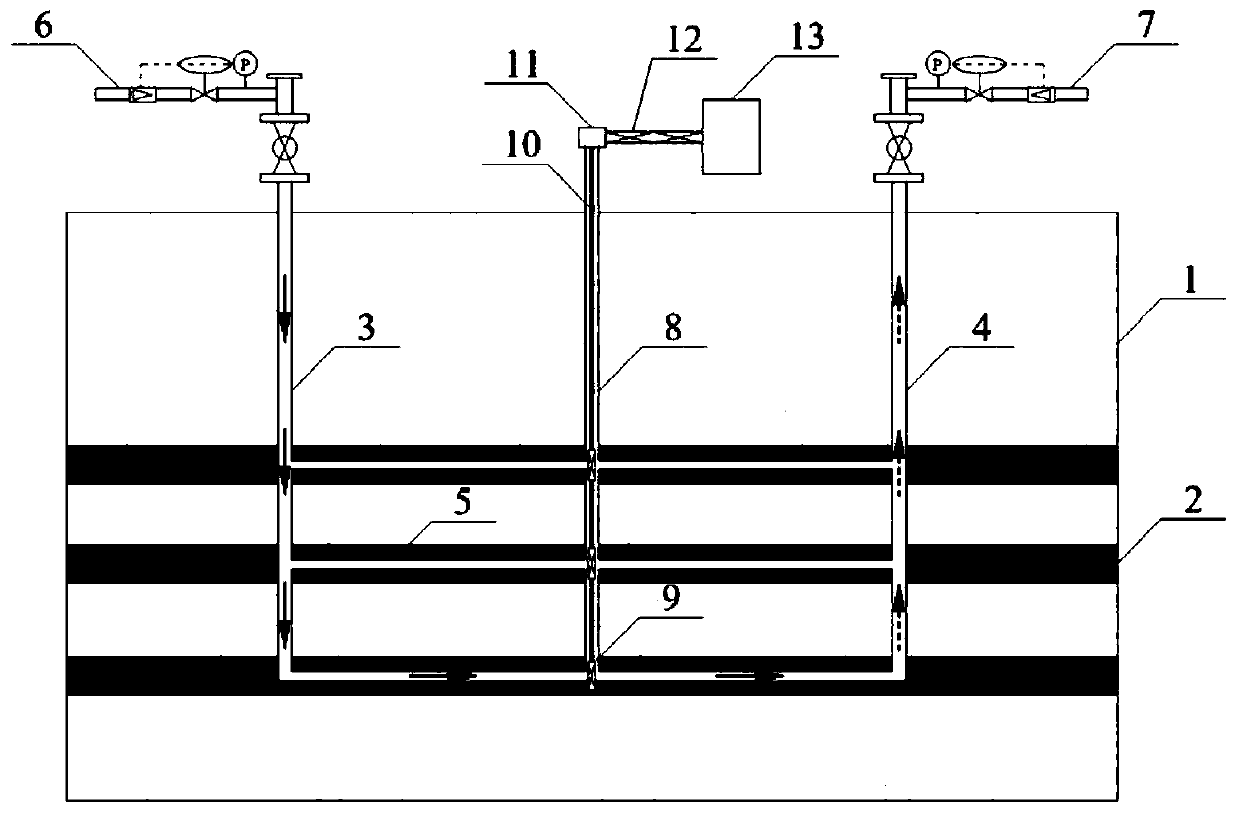

[0016] Below in conjunction with an embodiment in the accompanying drawings, the present invention will be further described:

[0017] Such as figure 1 As shown, the in-situ gasification mining method of extremely thin coal seam groups based on microwave radiation of the present invention, the specific process is as follows:

[0018] First, according to the geological information data of the ultra-thin coal seam, the air intake shaft 3 and the gas outlet shaft 4 are constructed from the ground through the rock formation 1 to the ultra-thin coal seam 2, and a horizontal well 5 is constructed from the intake shaft 3 in the ultra-thin coal seam 2. The very thin coal seam 2 is at least one layer, figure 1 Three floors are shown. The horizontal well 5 runs through the gas inlet well 3 and the gas outlet well 4, and the distance between the gas inlet shaft 3 and the gas outlet well 4 is 1000 meters. After that, connect the gas pipeline 6 at the wellhead of the gas inlet well 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com