Solid contact type ion-selective electrode and preparation and application thereof

A potassium ion and selective technology, applied in the field of potassium ion detection, can solve the problems of limiting the wide application of conductive polymers, complex preparation process of ionic liquids, and limiting wideness, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The specific preparation steps of the solid contact potassium ion selective electrode are as follows:

[0032] 1) Preparation of sensitive membrane: a total of 200 mg of a mixture of PVC particles, o-nitrophenyloctyl ether, potassium ionophore and tetrakis (3,5-bis (trifluoromethyl) phenyl) sodium borate, of which 32.8 wt % PVC pellets, 65.6 wt% o-nitrophenyloctyl ether, 1.0 wt% potassium ionophore, and 0.6 wt% sodium tetrakis(3,5-bis(trifluoromethyl)phenyl)borate were pipetted into 1.6 mL THF solution , Ultrasound, stirring for 2h to make it dispersed evenly.

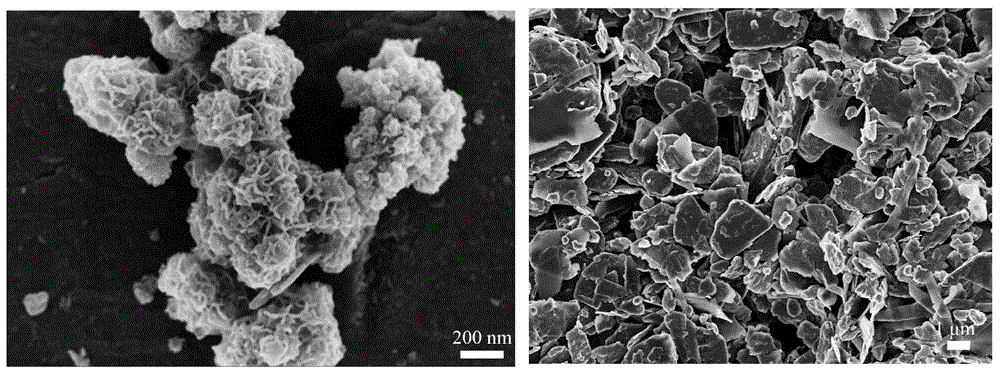

[0033] 2) MoS with flower-like microscopic morphology 2 Preparation of:

[0034] a. MoO 3 preparation.

[0035] Weigh 3.36g of Na 2 MoO 4 2H 2 O was dissolved in 70 mL of water and stirred for 1 h to obtain 0.2 M Na 2 MoO 4 solution, ready to use; measure 25mL of HNO 3 Dissolve in 100mL water to make 4M HNO 3 solution. Use a dropper to pipette a certain amount of HNO 3The solution was added dropwise...

Embodiment 2

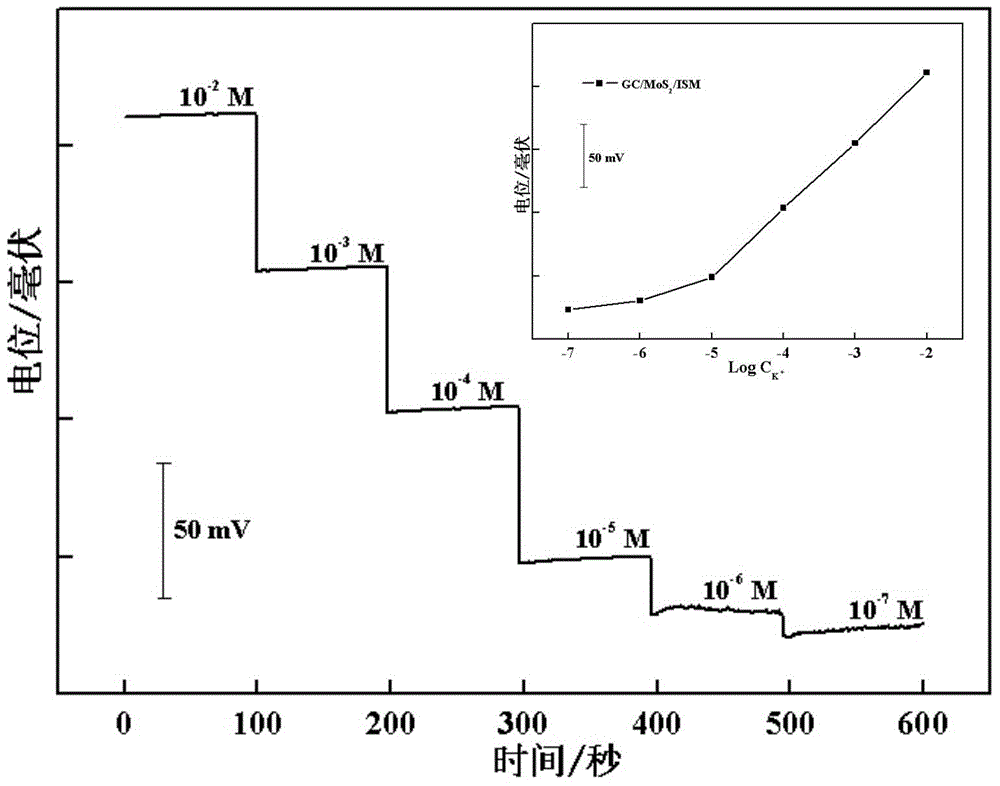

[0042] The electrodes obtained above should be conditioned at 10 -3 Activated in M potassium chloride solution for 24h.

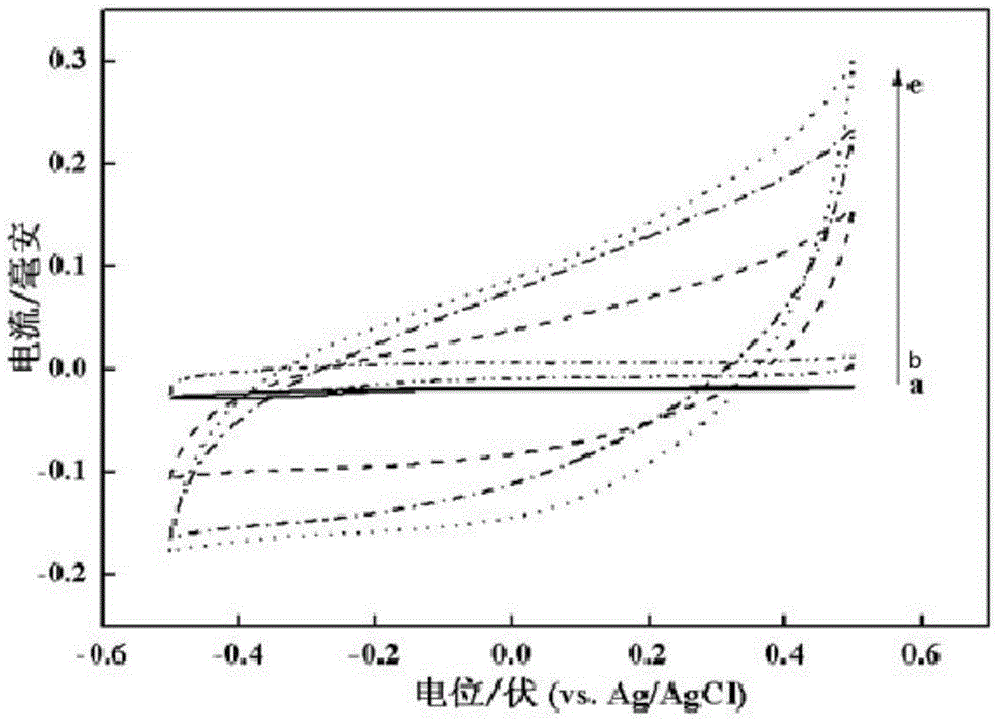

[0043] The activated electrode and the Ag / AgCl reference electrode with 3M KCl as the salt bridge solution constitute a loop, and are inserted into a series of potassium chloride solutions with different concentrations in turn (the concentration of potassium chloride solution is 10 -2 , 10 -3 , 10 -4 , 10 -5 ,10 -6 , 10 -7 mol / L), the open circuit potential values of solutions with different concentrations were measured by an electrochemical workstation, and the standard response curve of the measured potential and the corresponding ion concentration was drawn. Then, the electrode is placed in the liquid to be tested for potential measurement, and the concentration of potassium ions in the liquid to be tested can be determined by comparing with the standard response curve of the same potential-concentration. (see image 3 ).

[0044] Depend on ...

Embodiment 3

[0047] 1) Preparation of MoS with specific morphology 2 :MoO 3 The preparation process is carried out with reference to Step 2 of Example 1. Collect the MoO obtained by centrifugation 3 . Weigh 0.15g MoO 3 Disperse in 30mL of water, stir for 1h to make 0.035M MoO 3 Dispersions. Then weigh and add 0.51g NaSCN, continue to stir for 1h to mix the above mixed solution evenly, then transfer the above mixed solution into a 50mL polytetrafluoroethylene reactor, and react in a dry box at 180°C for 24h. After the reaction is completed, the natural Cool to room temperature and collect the product by centrifugation to obtain MoS 2 product.

[0048] 2) all the other implementation steps are carried out with reference to embodiment 1 step 3, 4 and embodiment 2, can obtain solid contact type potassium ion selective electrode to measure 10 -2 -10 -7 Potential change response of M potassium chloride solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com