Manufacturing method of high power type lithium battery system

A manufacturing method and high-power technology, applied in the direction of electrolytic storage battery manufacturing, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problem of capacity decay and cannot be discharged normally with high current, and overcome the problem of excessive large current discharge capacity decay, The effect of reducing the impedance and increasing the conduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

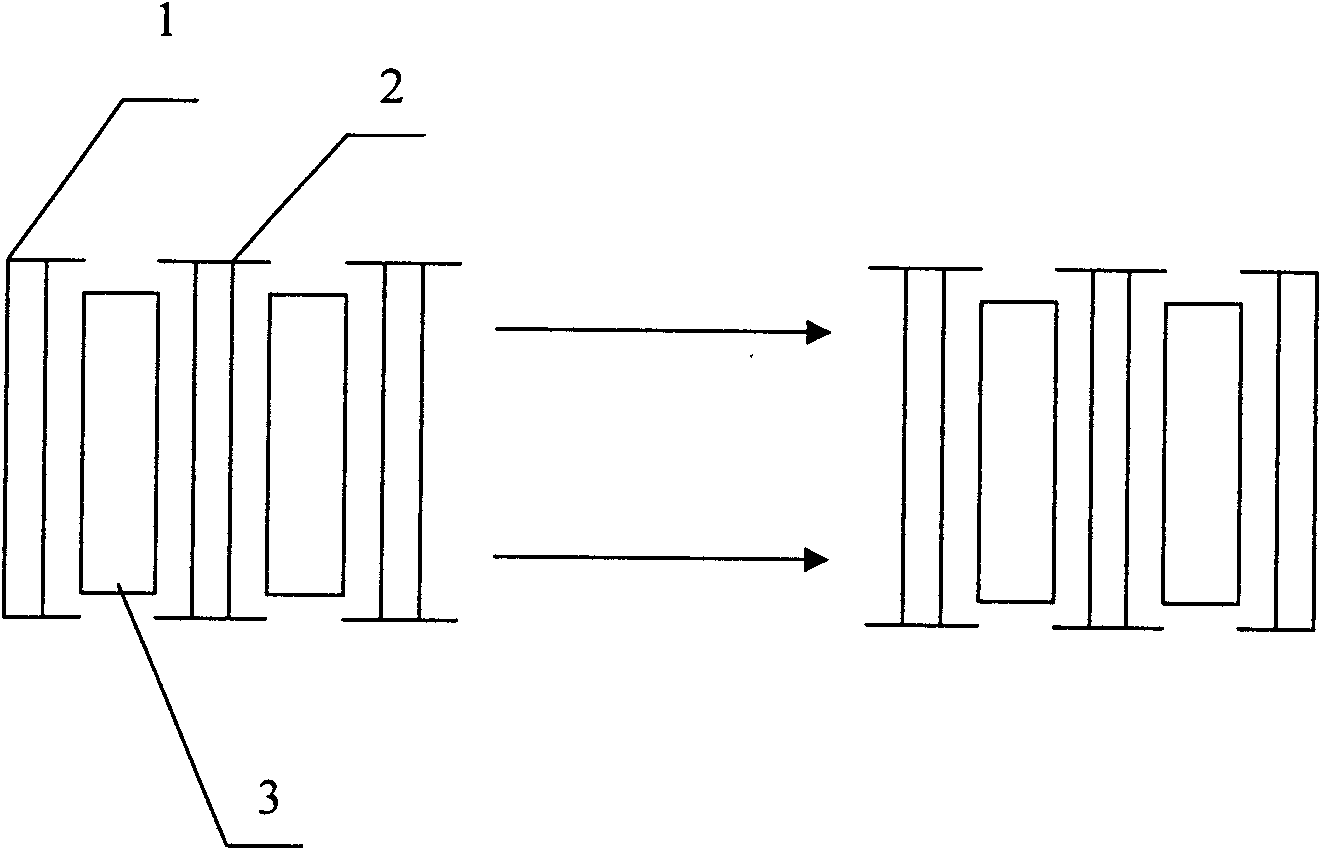

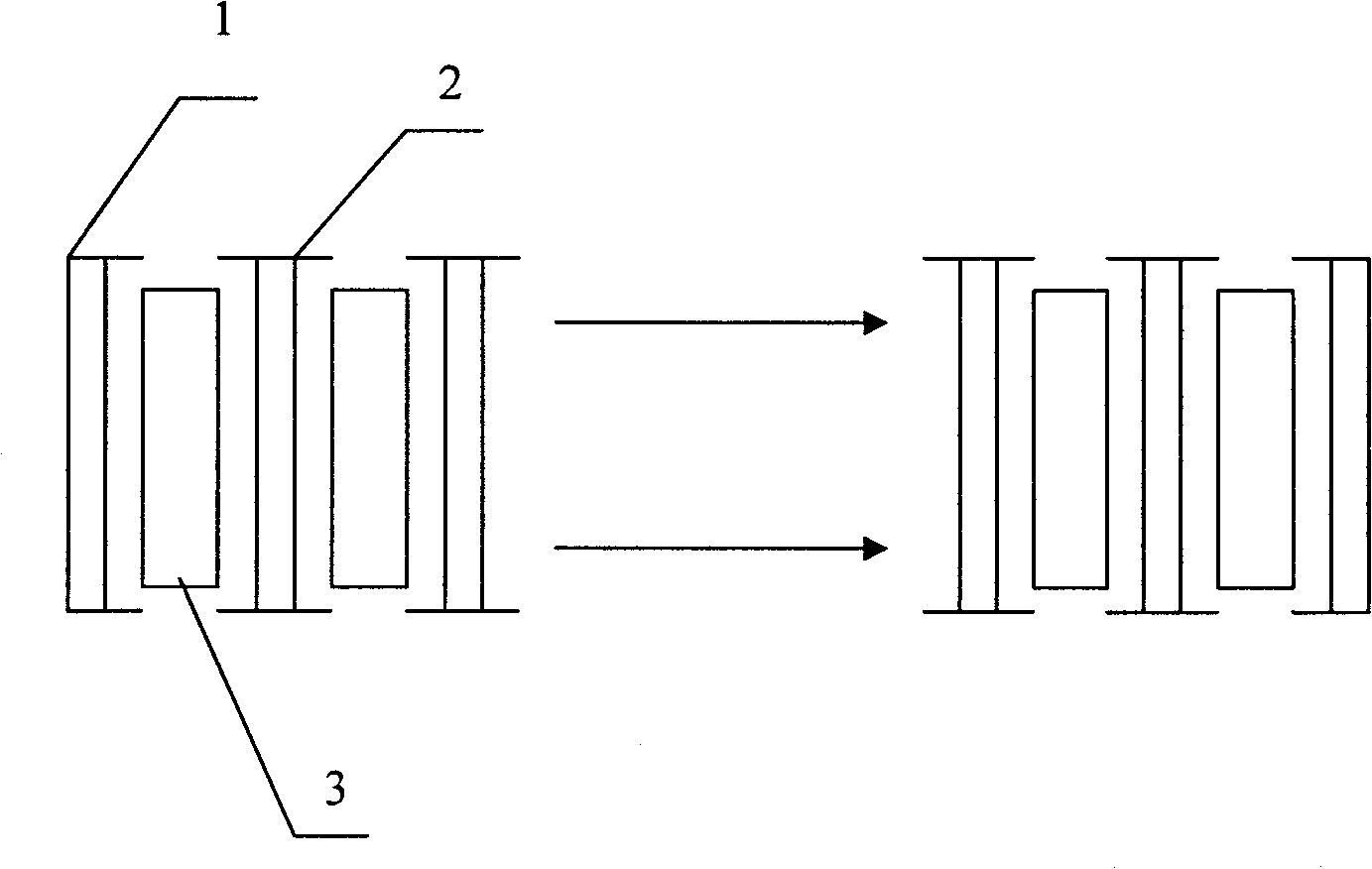

Image

Examples

Embodiment 1

[0024] Production of positive and negative electrode materials

[0025] Negative electrode material: power carbon powder accounts for 90% of the total weight, conductive agent SP is 2%, carbon fiber conductive material VGCF is 1.2%, thickener CMC is 1.8%, and water-based adhesive LA132 is 5%. Deionized water is about 50% of the total weight of the toner.

[0026] Positive electrode material: lithium manganate material accounts for about 89% of the total weight, conductive agent SP is 3.5%, conductive agent KS-15 is 3.5%, carbon fiber conductive material VGCF is 1%, binder PVDF (900) is 3%, The solvent NMP accounts for 52% of the total weight of the positive electrode material.

[0027] The positive electrode material is dried, and then the positive and negative electrode materials are uniformly stirred respectively.

[0028] Production process: ingredients→coating→baking→sheet making→spot welding→winding→one pack→liquid injection→formation→two seals→aging→volume separation→P...

Embodiment 2

[0036] Production of positive and negative electrode materials

[0037] Negative electrode material: power carbon powder accounts for 86% of the total weight, conductive agent SP is 4%, carbon fiber conductive material VGCF is 1.5%, thickener CMC is 3%, and water-based adhesive LA132 is 5.5%. Deionized water is about 55% of the total weight of the toner.

[0038] Positive electrode material: lithium manganate material accounts for about 86% of the total weight, conductive agent SP is 4%, conductive agent KS-15 is 5%, carbon fiber conductive material VGCF is about 3%, binder PVDF (900) is 2% , the solvent NMP accounts for 58% of the total weight of the positive electrode material of the battery.

[0039] The positive electrode material is dried, and then the positive and negative electrode materials are uniformly stirred respectively.

[0040] Production process: ingredients→coating→baking→sheet making→spot welding→winding→one pack→liquid injection→formation→two seals→aging→v...

Embodiment 3

[0048] Production of positive and negative electrode materials

[0049] Negative electrode material: power carbon powder accounts for 81% of the total weight, conductive agent SP accounts for 14.5%, carbon fiber conductive material VGCF accounts for 0.5%, thickener CMC accounts for 0.5%, and water-based adhesive LA132 accounts for 3.5%. Deionized water is about 65% of the total weight of the toner

[0050] Positive electrode material: lithium manganate material accounts for about 88% of the total weight, conductive agent SP is 5%, conductive agent KS-15 is 0.5%, carbon fiber conductive material VGCF is about 3%, binder PVDF (900) is 3.5% . The solvent NMP accounts for 62% of the total weight of the positive electrode material.

[0051] The positive electrode material is dried, and then the positive and negative electrode materials are uniformly stirred respectively.

[0052] Production process: ingredients→coating→baking→sheet making→spot welding→winding→one pack→liquid inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com