Preparation method for high-performance n-type bismuth telluride base thermoelectricity power generation material

A bismuth telluride-based, thermoelectric power generation technology, which is applied in the manufacture/processing of thermoelectric devices, etc., can solve the problem that the performance of n-type bismuth telluride-based materials is not significantly improved, cannot be mass-produced stably in industrialized production, and reduces lattice thermal conductivity. rate and other issues, to achieve long-term stable performance, uniform performance, and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

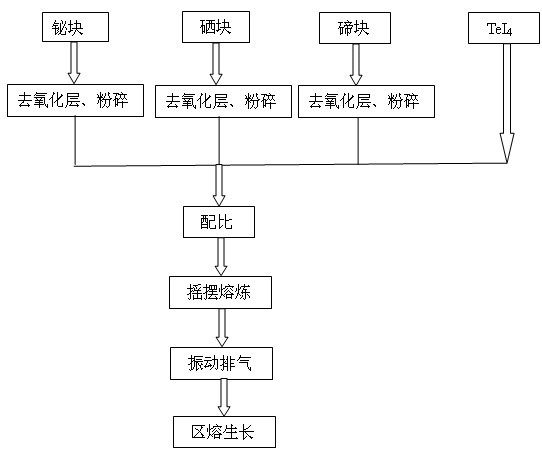

[0029] see figure 2 , a method for preparing a high-performance n-type bismuth telluride-based thermoelectric power generation material, the preparation steps are as follows:

[0030] (1) Use a copper wire brush or a blade to remove the oxide layer on the surface of the tellurium block, bismuth block and selenium block with a commercial purity of 4N, and then pulverize them with a pulverizer;

[0031] (2) Seal one end of the glass tube with an inner diameter of 32 mm with a propane lamp and fully anneal it for 2 minutes. After cleaning with deionized water, dehydrate with alcohol and dry for later use;

[0032] (3) According to the stoichiometric ratio Bi 2 (Te 1-x Se x ) 3 +ywt%TeI 4 , x=0.07, y=0.15, take a total of 1.70Kg of Bi, Se and Te pulverization, add 0.15wt% TeI 4 placed in a dried glass tube;

[0033] (4) After the vacuum degree of the glass tube containing the material is evacuated to 4Pa, seal it at a place 3cm away from the material plane;

[0034] (5) ...

Embodiment 2

[0039] A method for preparing a high-performance n-type bismuth telluride-based thermoelectric power generation material, the preparation steps of which are as follows:

[0040] (1) Use a copper wire brush or a blade to remove the oxide layer on the surface of the tellurium block, bismuth block and selenium block with a commercial purity of 4N, and then pulverize them with a pulverizer;

[0041] (2) Seal one end of the glass tube with an inner diameter of 35mm with a gas lamp and fully anneal for ≥ 3 minutes. The edge of the other end is melted and smoothed. Rinse off the attachments in the glass tube with tap water, and then use glass cleaner, tap water, deionized After cleaning with water, dehydrate with alcohol and dry for later use;

[0042] (3) According to the stoichiometric ratio Bi 2 (Te 1-x Se x ) 3 +ywt%TeI 4 , x=0.06, y=0.14, a total of 1.9Kg of Bi, Se and Te pulverized products, adding 0.14wt% TeI 4 placed in a dried glass tube;

[0043] (4) After the vacuum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com