Bismuth-telluride-based thermoelectric electrification device and manufacturing method thereof

A bismuth telluride-based, thermoelectric power generation technology is applied in the manufacture/processing of thermoelectric devices, thermoelectric device components, thermoelectric devices using only the Peltier or Seebeck effect, etc. Cost and other issues, to achieve the effect of reducing costs, reducing workload and scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

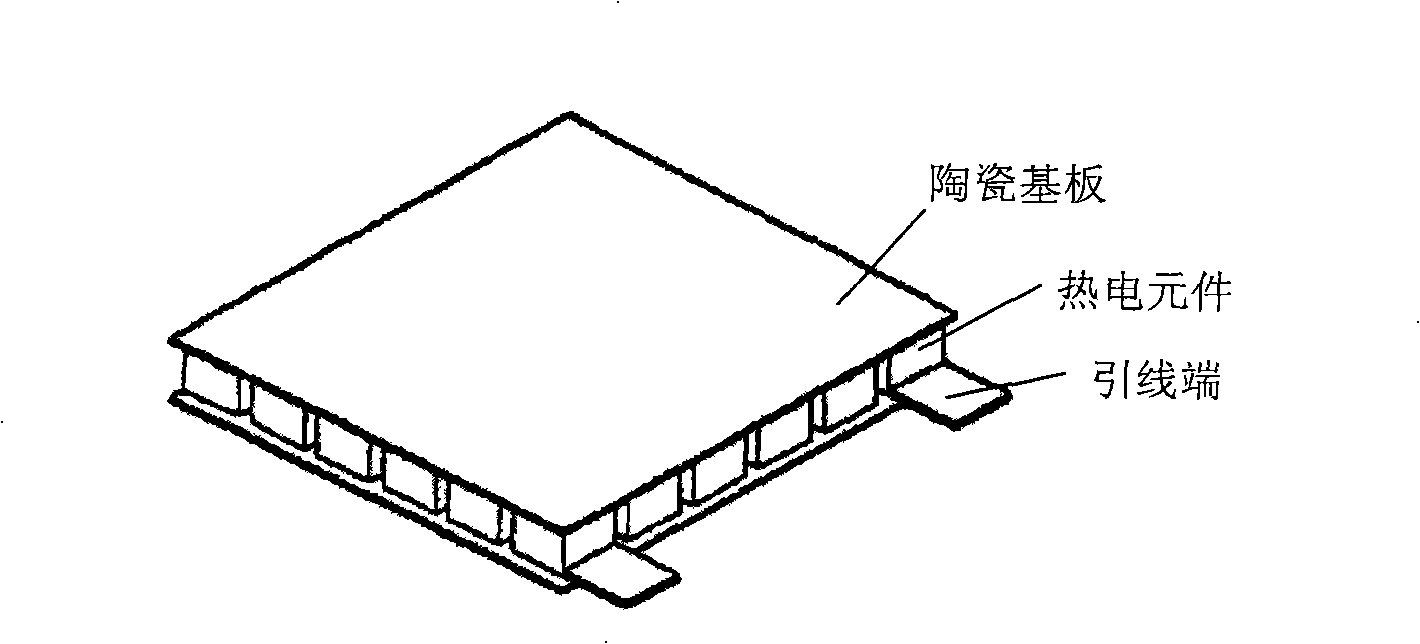

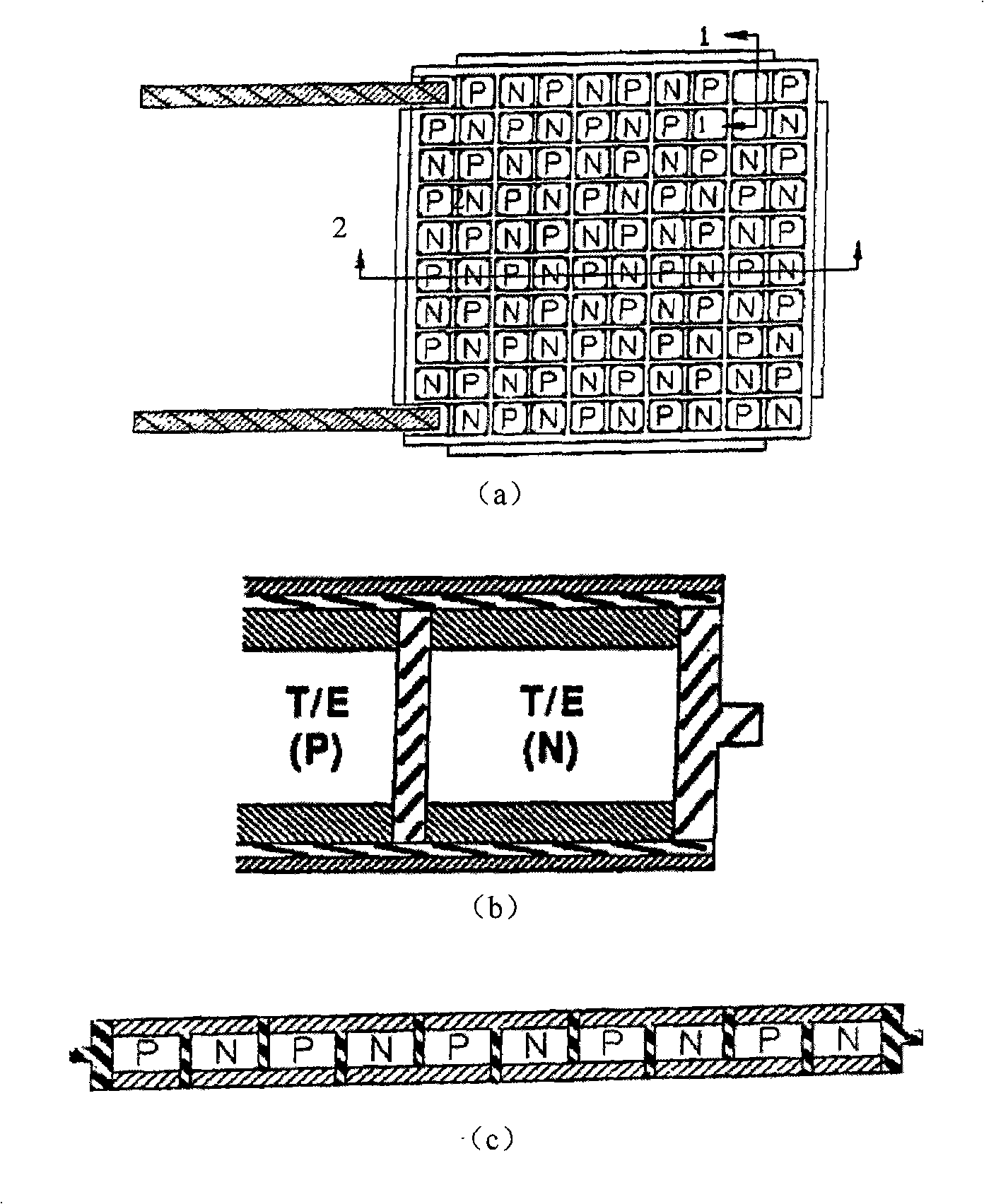

[0026] Further illustrate substantive characteristics and remarkable progress of the present invention below in conjunction with accompanying drawing.

[0027] The manufacturing method of the bismuth telluride-based thermoelectric power generation device of the present invention includes six steps: preparation of a porous support frame, preparation of components, loading of components, soldering of cold-end electrodes, spraying of hot-end electrodes, and grinding of sprayed surfaces. Now elaborate as follows:

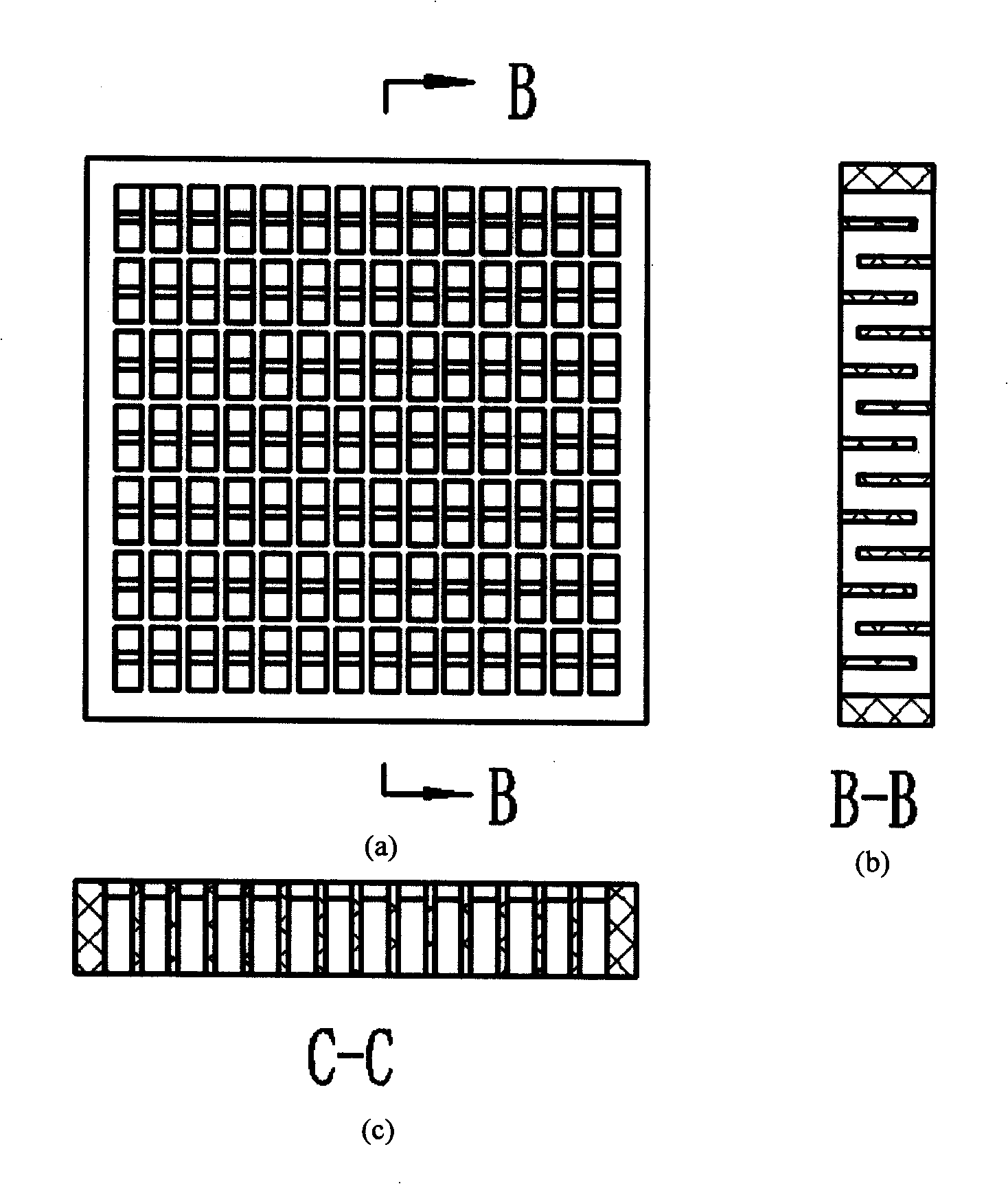

[0028] 1) Preparation of porous scaffolds. Select high-temperature-resistant resin (trade name: PBB) as the material of the porous support frame 10, heat the material to a liquid state, pour it into a preheated mold, keep the pressure, form, pass water to cool the mold to room temperature, and take out the support frame. Porous support frame 10 such as image 3 As shown, the holes of the porous support frame are straight holes, without slopes and component positioning...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com