Preparation method of preferentially oriented n-type bismuth telluride-based polycrystalline bulk thermoelectric material

A bismuth telluride-based, preferred orientation technology, applied in chemical instruments and methods, selenium/tellurium compounds, metal selenides/tellurides, etc., can solve the problem that it is difficult to prepare powders with uniform particle size, and achieve dimensionless thermoelectric optimization High value, stable performance and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

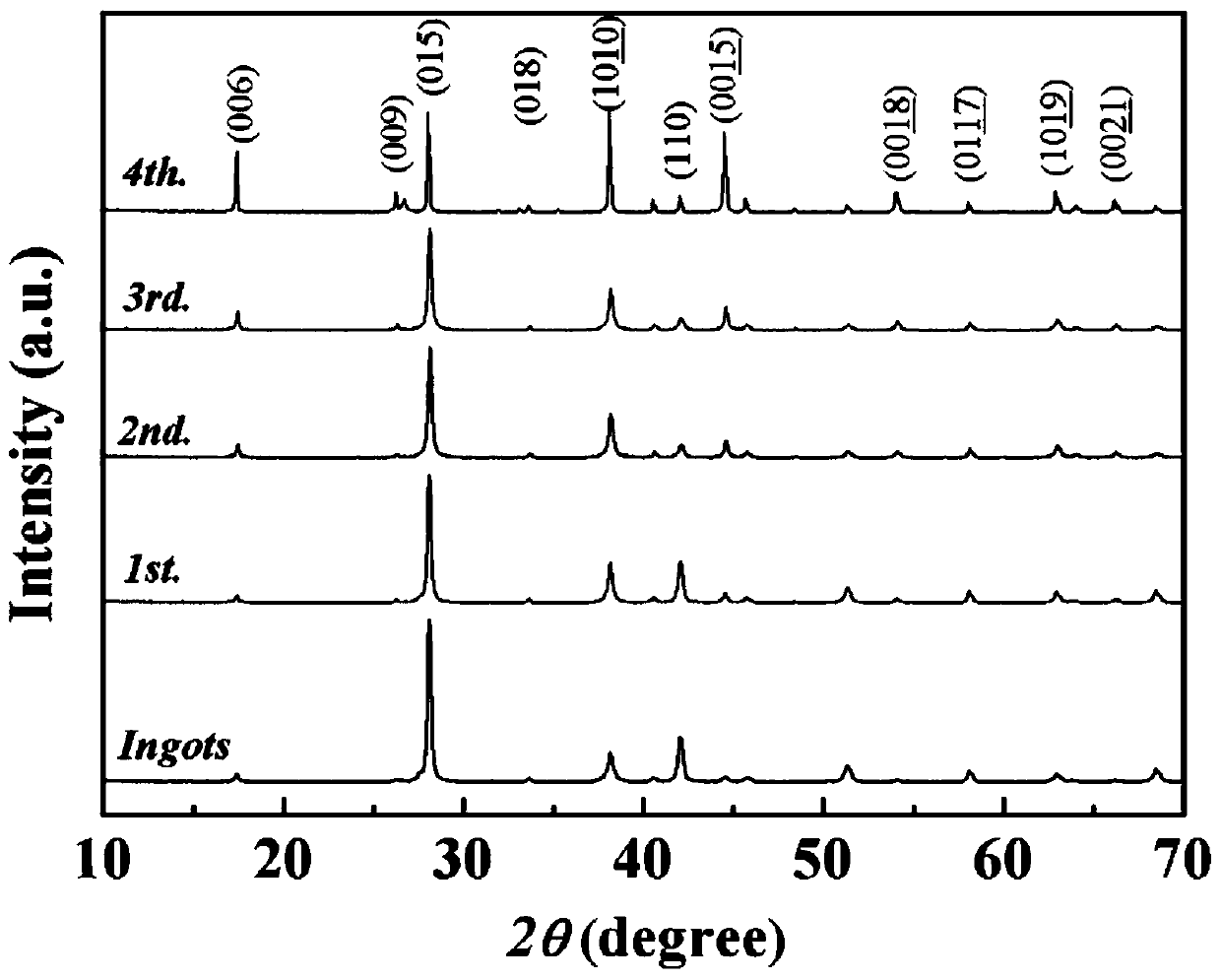

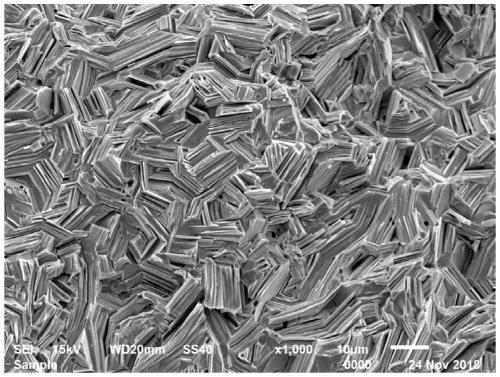

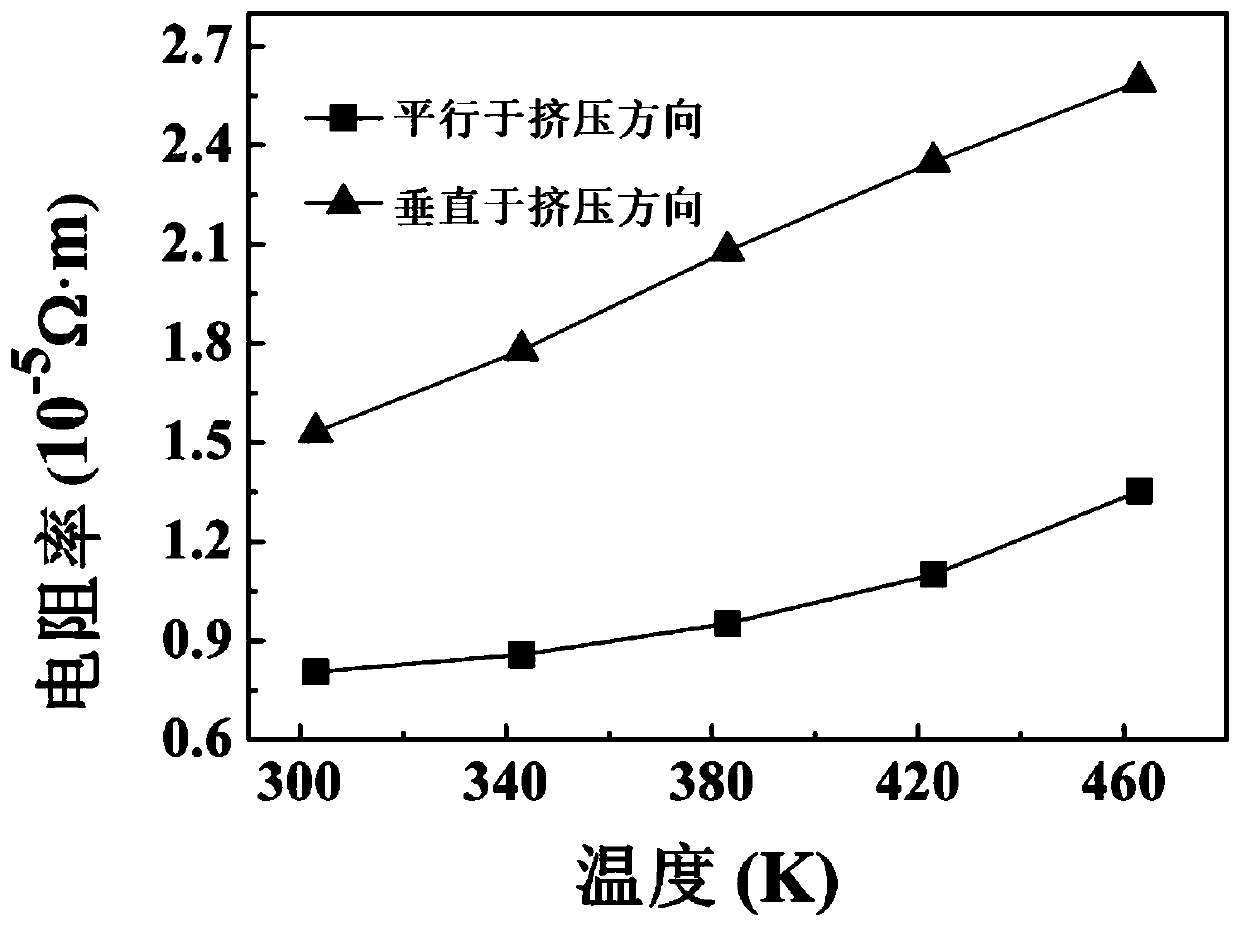

[0031] The preparation method of the preferred orientation n-type bismuth telluride-based polycrystalline bulk thermoelectric material provided in this example is as follows:

[0032] Using Bi, Te and Se elemental powders with a mass percentage greater than 99.99% as raw materials, according to Bi 2 Te 2.79 Se 0.21 Stoichiometric ratio ingredients;

[0033] Put the above-mentioned raw materials into a quartz glass tube or a high borosilicate glass tube and vacuum seal it, then put the sealed quartz glass tube or high borosilicate glass tube into a swing furnace for high-temperature melting, the melting temperature is 630°C, and the melting time is 5min. After the smelting is completed, the hearth of the swing furnace is rotated to a vertical position, and slowly cooled to obtain a high-density n-type bismuth telluride-based alloy ingot;

[0034] Cut the obtained n-type bismuth telluride-based alloy crystal bar into blocks, put the blocks into an equal-channel corner extrus...

Embodiment 2

[0041] The preparation method of the preferred orientation n-type bismuth telluride-based polycrystalline bulk thermoelectric material provided in this example is as follows:

[0042] Using Bi, Te and Se elemental powders with a mass percentage greater than 99.99% as raw materials, according to Bi 2 Te 2.7 Se 0.3 Stoichiometric ratio ingredients;

[0043] Put the above-mentioned raw materials into a quartz glass tube or a high borosilicate glass tube and vacuum seal it, then put the sealed quartz glass tube or high borosilicate glass tube into a swing furnace for high-temperature melting, the melting temperature is 630°C, and the melting time is 5min. After the smelting is completed, the hearth of the swing furnace is rotated to a vertical position, and slowly cooled to obtain a high-density n-type bismuth telluride-based alloy ingot;

[0044] Cut the obtained n-type bismuth telluride-based alloy crystal bar into blocks, put the blocks into an equal-channel corner extrusio...

Embodiment 3

[0052] The preparation method of the preferred orientation n-type bismuth telluride-based polycrystalline bulk thermoelectric material provided in this example is as follows:

[0053] Using Bi, Te and Se elemental powders with a mass percentage greater than 99.99% as raw materials, according to Bi 2 Te 2.4 Se 0.6 Stoichiometric ratio ingredients;

[0054] Put the above-mentioned raw materials into a quartz glass tube or a high borosilicate glass tube and vacuum seal it, then put the sealed quartz glass tube or high borosilicate glass tube into a swing furnace for high-temperature melting, the melting temperature is 630°C, and the melting time is 10min. After the smelting is completed, the hearth of the swing furnace is rotated to a vertical position, and slowly cooled to obtain a high-density n-type bismuth telluride-based alloy ingot;

[0055] Cut the obtained n-type bismuth telluride-based alloy crystal bar into blocks, put the blocks into an equal-channel corner extrusi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com