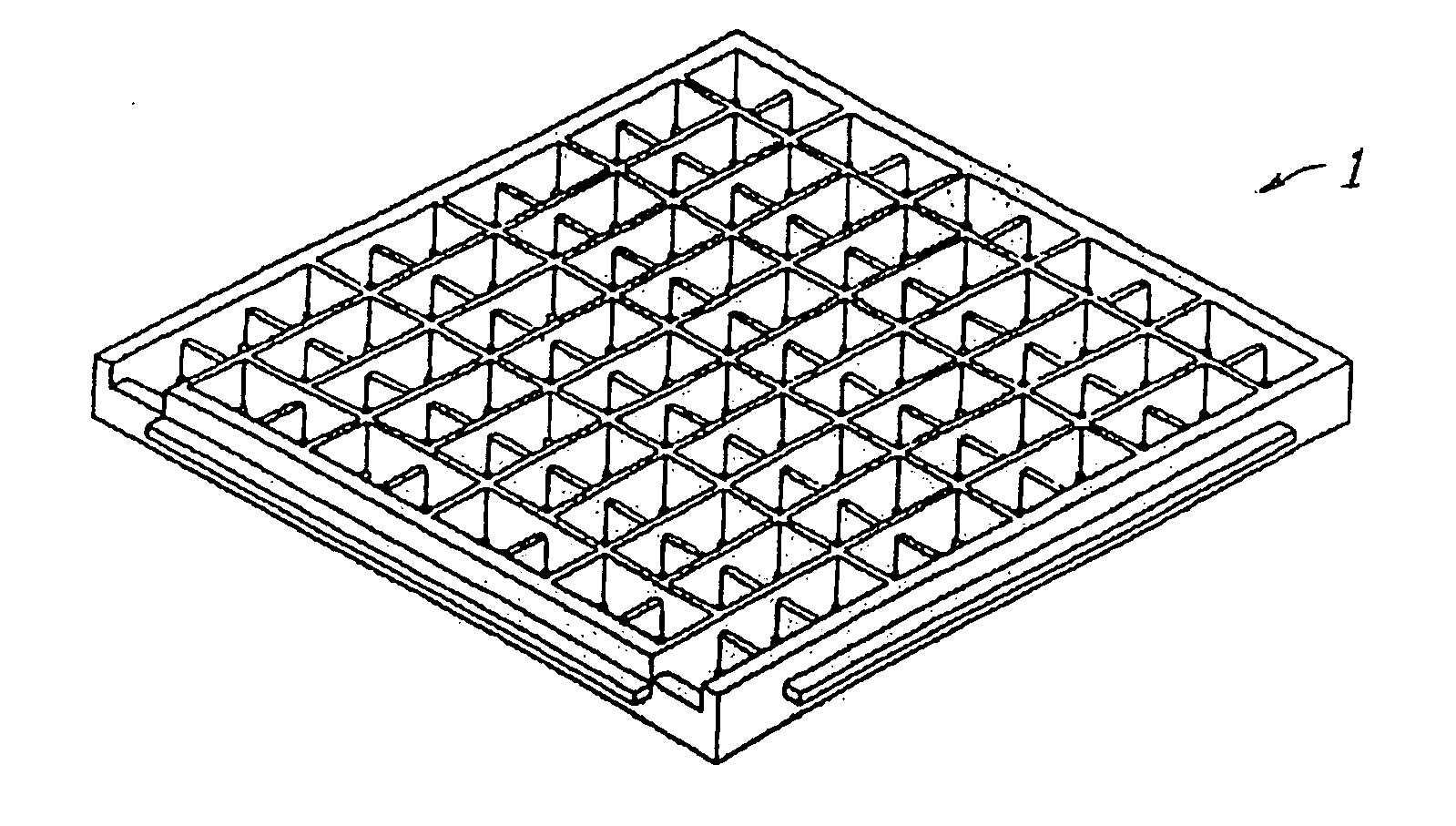

High temperature compact thermoelectric module with gapless eggcrate

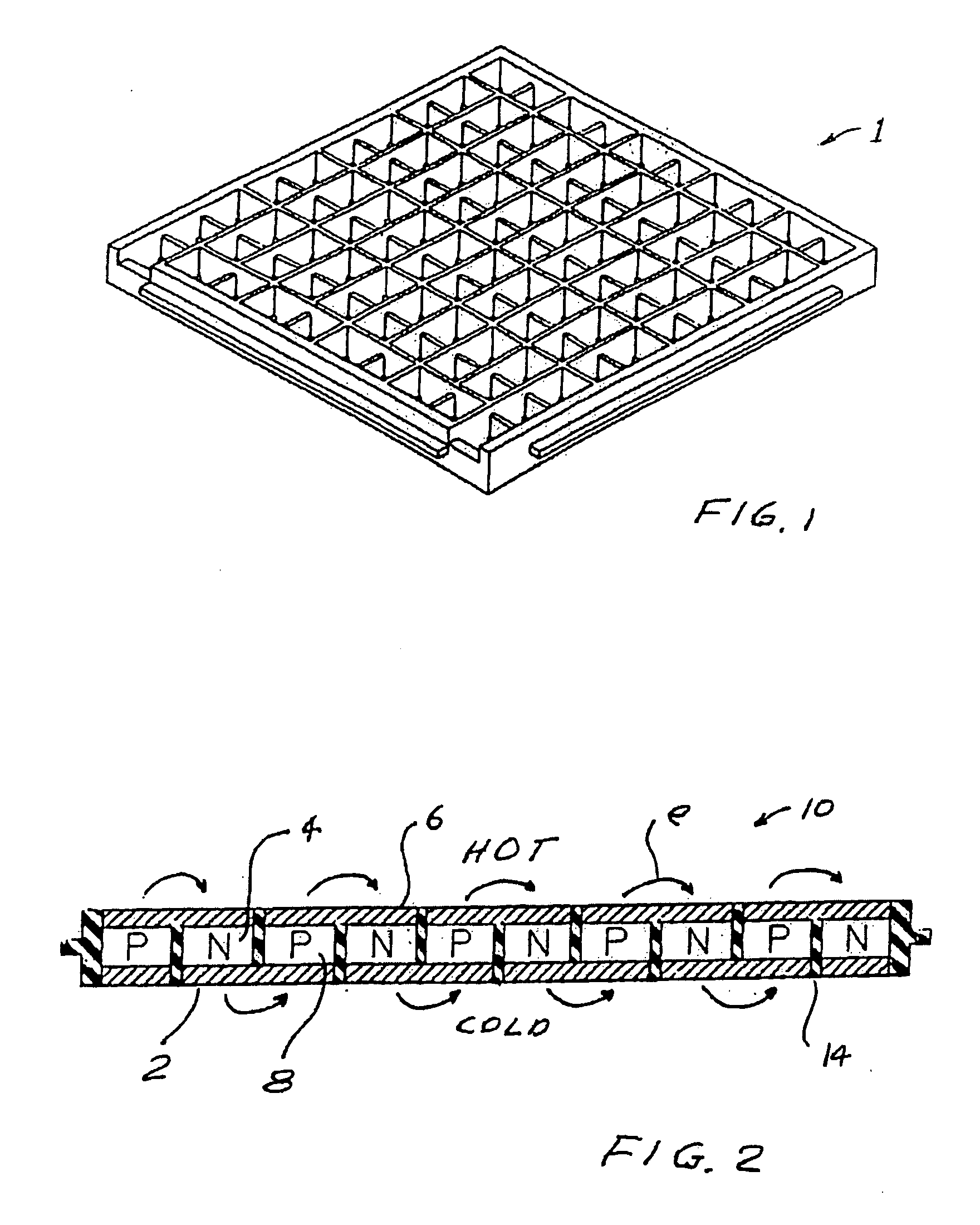

a thermoelectric module and compact technology, applied in the field of thermoelectric modules, can solve the problems of large over-example of the prior-art thermoelectric module, short circuit, and marginal strength of the micro-structure, and achieve the effect of low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first preferred embodiment

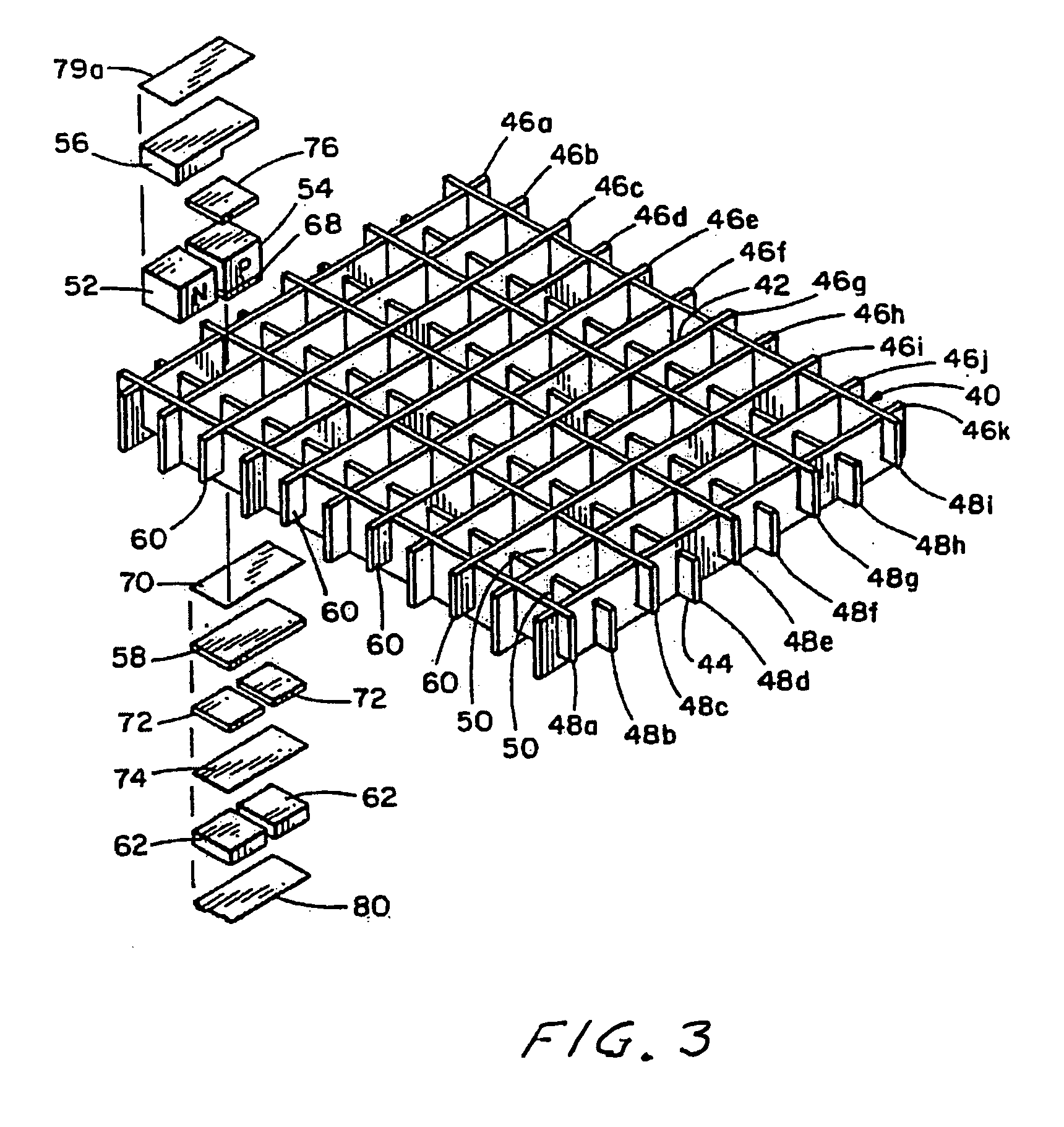

[0020]A first preferred embodiment of the present invention can be described by reference to FIGS. 4 and 4A. The drawing is similar to the FIG. 3 drawing, but the module is greatly improved from the module described in U.S. Pat. No. 4,611,089.

The Egg-Crate

[0021]Egg-crate 70 is injection molded using a technique similar to that described in U.S. Pat. No. 5,875,098. However, the molding process in substantially more complicated. The egg-crate comes in two molded together sections. It includes an upper section (which will lie adjacent to a hot side) molded from stabilized zirconium oxide (ZrO2). ZrO2 has a very high melting point of 2715° C. and a very low thermal conductivity for an oxide. The egg-crate also includes a lower side (which will lie adjacent to a cold side) molded from Zenite Model 7130 available from Dow Chemical that has a melting point of 350° C. but very low thermal conductivity.

[0022]The ZrO2 portion of the egg-crate is fabricated by injection molding of the ZrO2 pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com