Method for preparing high-performance p-type bismuth telluride-based thermoelectric materials

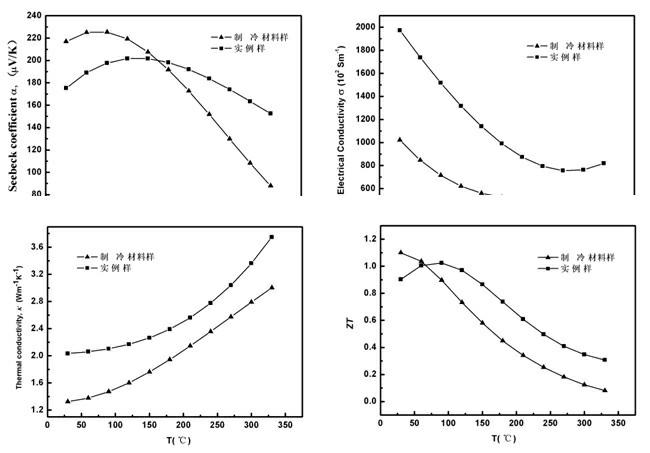

A bismuth telluride-based, thermoelectric power generation technology is applied in chemical instruments and methods, polycrystalline material growth, self-regional melting method, etc. rate and other issues, to achieve the effect of uniform performance, simple equipment and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

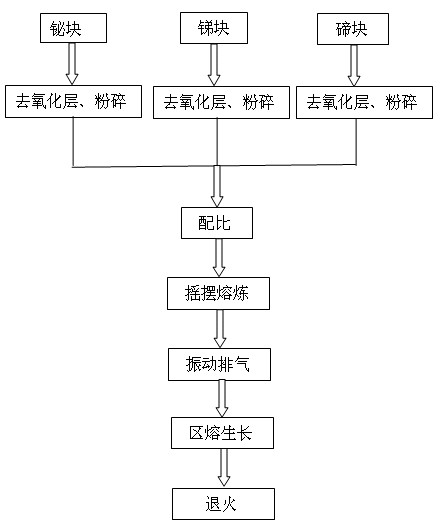

[0028] see figure 2 , a method for preparing a high-performance p-type bismuth telluride-based thermoelectric power generation material, the preparation steps are as follows:

[0029] (1) Use a copper wire brush or a blade to remove the oxide layer on the surface of the tellurium block, bismuth block and antimony block with a purity of 4N, and then pulverize them with a pulverizer;

[0030] (2) Seal one end of the glass tube with an inner diameter of 32 mm with a propane lamp and fully anneal it for 2 minutes. After cleaning with deionized water, dehydrate with alcohol and dry for later use;

[0031] (3) According to the stoichiometric ratio (Bi 0.26 Sb 0.74 ) 2 Te 3.01 , weigh a total of 1.70Kg of Bi, Sb and Te pulverized objects and place them in a dried glass tube;

[0032] (4) After evacuating the vacuum degree of the glass tube containing the material to 4Pa, seal it at a place 3cm away from the material plane;

[0033] (5) The sealed glass tube is placed in a swi...

Embodiment 2

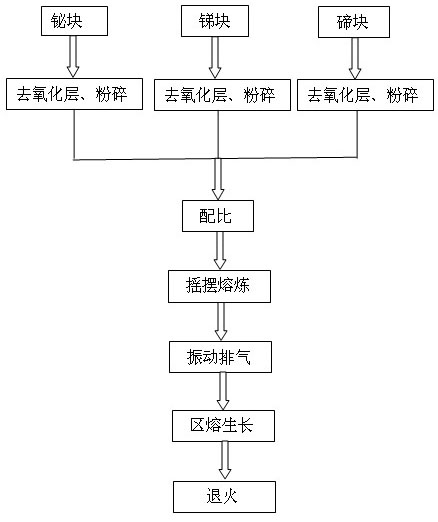

[0039] A method for preparing a high-performance p-type bismuth telluride-based thermoelectric power generation material, the preparation steps of which are as follows:

[0040] (1) Use a copper wire brush or a blade to remove the oxide layer on the surface of the tellurium block, bismuth block and antimony block with a purity of 4N, and then pulverize them with a pulverizer;

[0041](2) Seal one end of the glass tube with an inner diameter of 35 mm with a gas lamp and fully anneal it for ≥ 3 minutes. After cleaning with deionized water, dehydrate with alcohol and dry for later use;

[0042] (3) According to the stoichiometric ratio (Bi 0。25 Sb 0。75 ) 2 Te 3.00 , weigh Bi, Sb and Te pulverized objects and place them in dried glass tubes;

[0043] (4) After the vacuum degree of the glass tube containing the material is evacuated to 3Pa, seal it at a place 4cm away from the material plane;

[0044] (5) Put the sealed glass tube in a swing melting furnace at 600~700°C, swin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com