Low power thermoelectric generator

a generator and low-power technology, applied in the field of self-sufficient, low-power thermoelectric generators, can solve the problems of reducing the repeatability of the device, requiring numerous manufacturing steps, and discharging the power supplied by the battery, so as to improve the repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

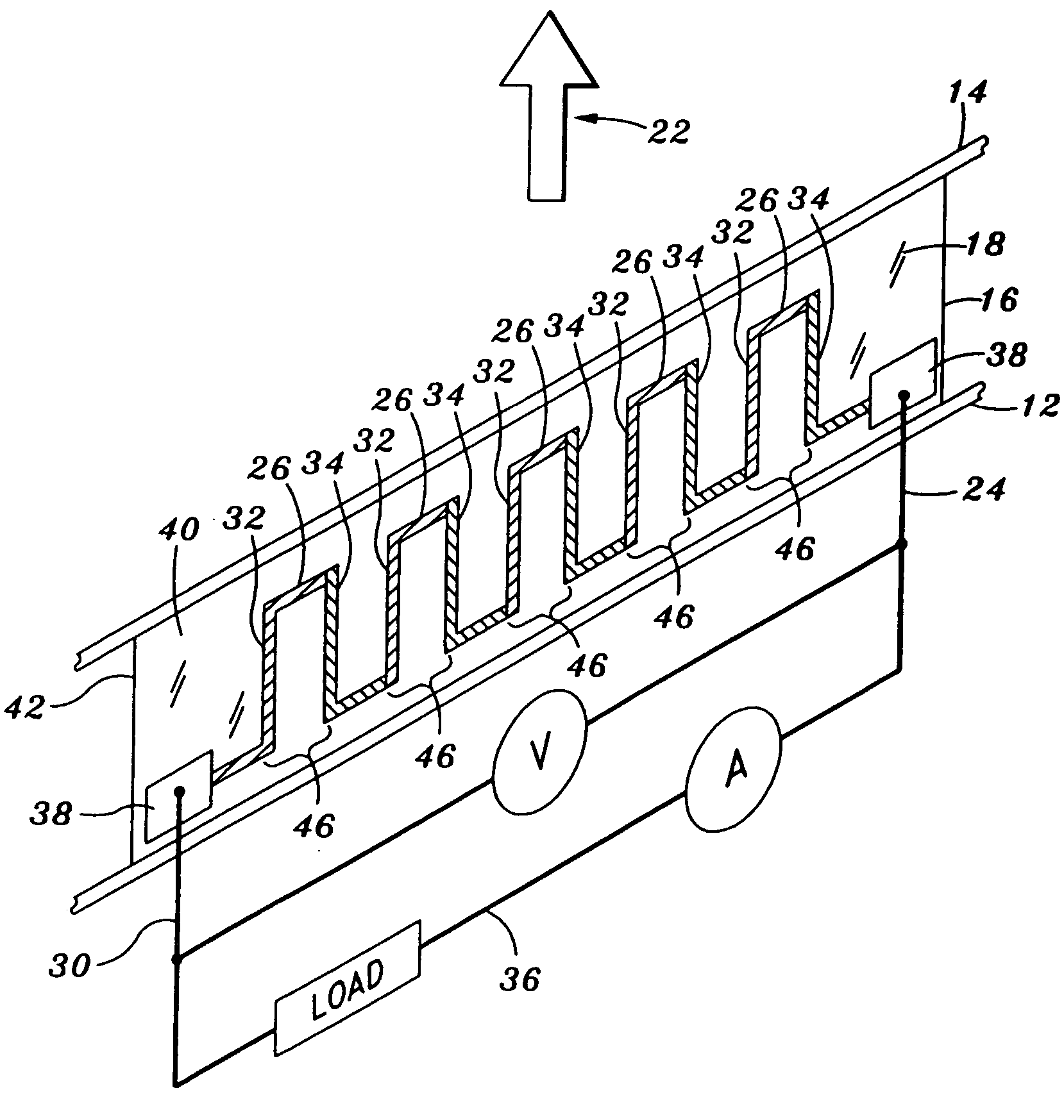

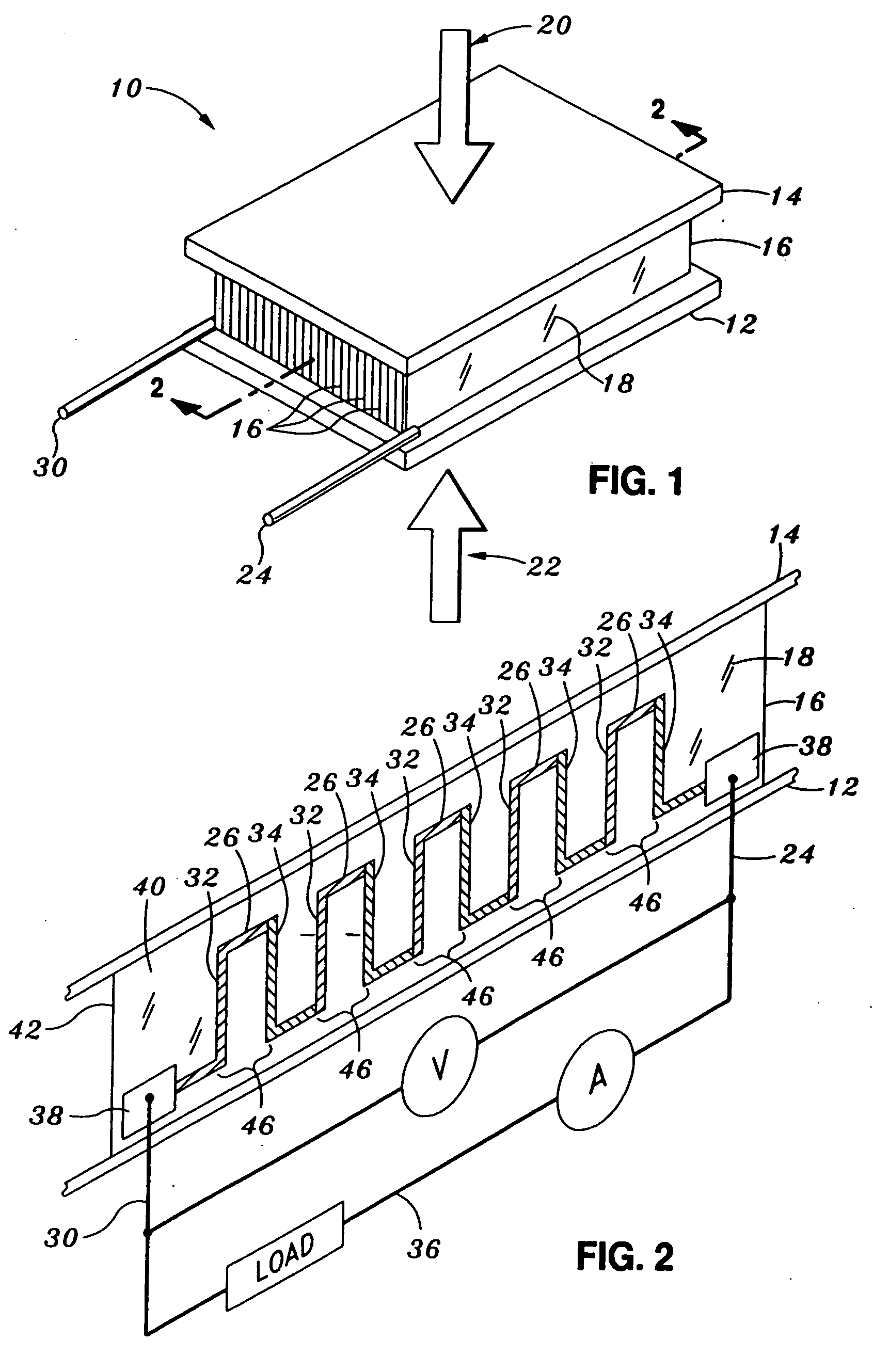

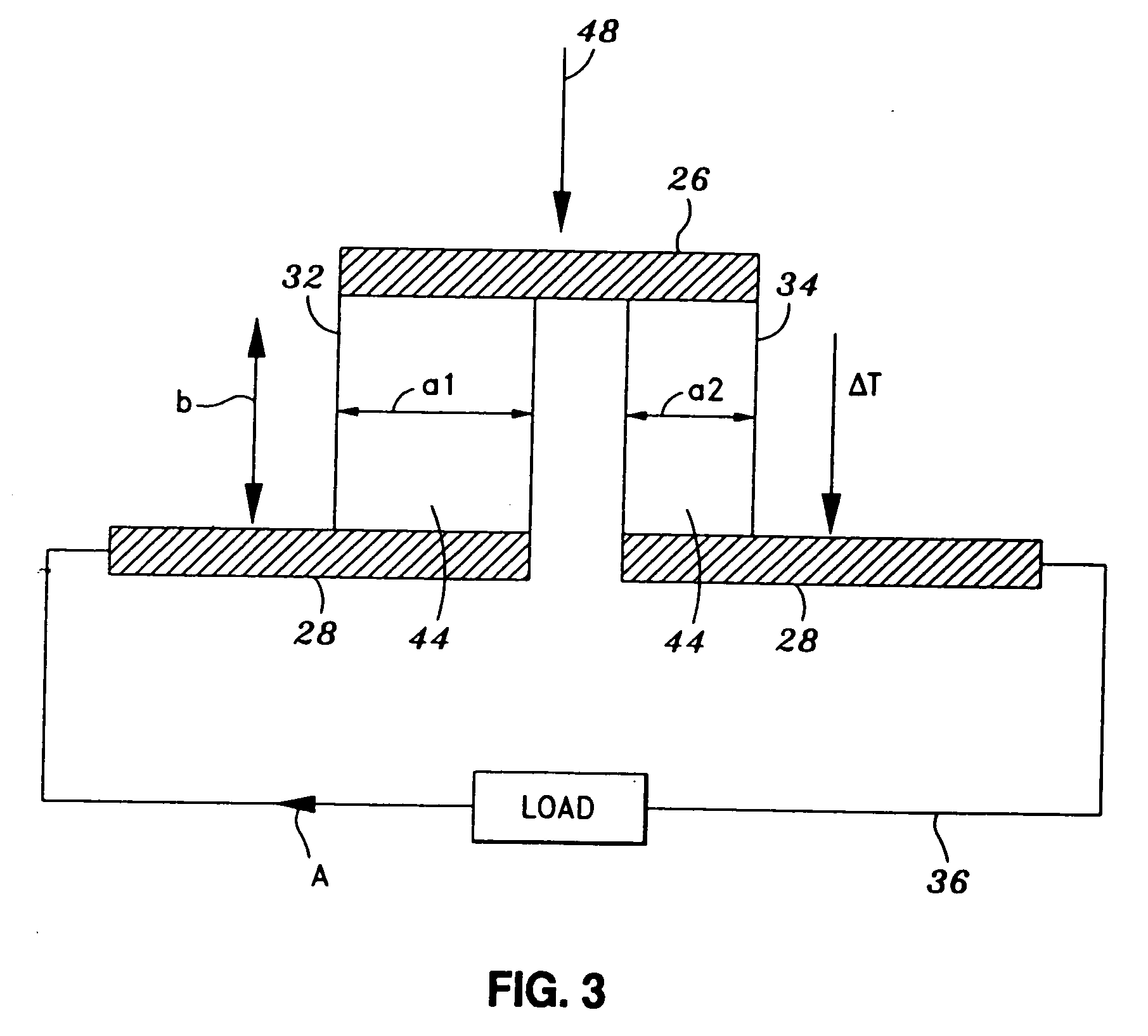

[0027] Referring now to the drawings wherein the showings are for purposes of illustrating preferred embodiments of the present invention and not for purposes of limiting the same, FIG. 1 is a perspective view of the thermoelectric generator 10 within which a foil segment 16 of the present invention may be utilized. As mentioned above, the thermoelectric generator 10 takes advantage of a thermal gradient to generate useful power according to the Seebeck effect. The thermoelectric generator 10 is typically comprised of a bottom plate 12, a top plate 14, and an array of foil segments 16. The array of foil segments 16 are interposed between the bottom plate 12 and the top plate 14 in side-by-side arrangement, with each one of the foil segments 16 being perpendicularly disposed between and in thermal contact with the bottom and top plates 12, 14. A series of generally elongate, alternating n-type and p-type thermoelectric legs 32, 34 is disposed on a substrate 18 of each one of the foil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com