Method for preparing nanocomposite by using two-dimensional transition metal chalcogenide nanosheets and metal

A technology of transition metal chalcogenides and nanocomposites, applied in the preparation of sulfide/polysulfide, binary selenium/tellurium compounds, nanotechnology for materials and surface science, etc., can solve the problem of silver disulfide that cannot be realized Molybdenum composite materials can control the problems of preparation and complex operation, and achieve the effects of easy processing, good water dispersion and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

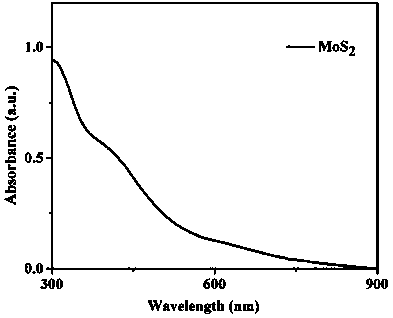

[0033] (a) MoS 2 Preparation of nanosheets

[0034] Add 800 mg of MoS to a 50 mL Schlenk tube 2 , Remove the air in the reaction tube with high-purity argon, then seal it, and slowly add 25 mL of n-butyllithium solution dropwise. After stirring at room temperature for 48 h, stop the reaction and let it stand for 2 to 4 h, remove the n-butyllithium solution in the upper part of the reaction tube, and convert the obtained single-layer or several-layer MoS 2 The nanosheets are dispersed in aqueous solution. Centrifugal purification to obtain a certain concentration of water-soluble MoS 2 Nanosheets.

[0035] (b) Preparation of reducing agent and stabilizer

[0036] Add 176.14 mg of ascorbic acid (AA) and 10 mL of ultrapure water to a 20 mL sample bottle to obtain a 100 mmol / L reducing agent solution; add 264.2 mg of sodium carboxymethylcellulose (CMC) to a 20 mL sample bottle, 10 mL of ultrapure water to obtain a 100 mmol / L stabilizer solution.

[0037] (c) Preparation of ...

Embodiment 2

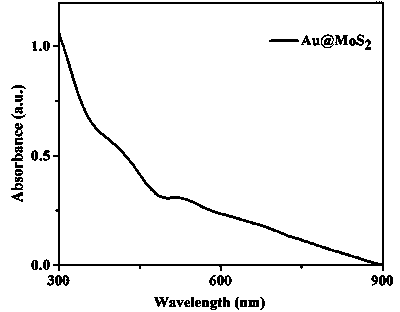

[0042] (a) MoS 2 Preparation of nanosheets

[0043] Add 800 mg of MoS to a 50 mL Schlenk tube 2 , Remove the air in the reaction tube with high-purity argon, then seal it, and slowly add 25 mL of n-butyllithium solution dropwise. After stirring at room temperature for 48 h, stop the reaction and let it stand for 2 to 4 h, remove the n-butyllithium solution in the upper part of the reaction tube, and convert the obtained single-layer or several-layer MoS 2 The nanosheets are dispersed in aqueous solution. Centrifugal purification to obtain a certain concentration of water-soluble MoS 2 Nanosheets.

[0044] (b) Preparation of reducing agent and stabilizer

[0045] Add 176.14 mg of ascorbic acid (AA) and 10 mL of ultrapure water to a 20 mL sample bottle to obtain a 100 mmol / L reducing agent solution; add 264.2 mg of sodium carboxymethylcellulose (CMC) to a 20 mL sample bottle, 10 mL of ultrapure water to obtain a 100 mmol / L stabilizer solution.

[0046] (c) Preparation of ...

Embodiment 3

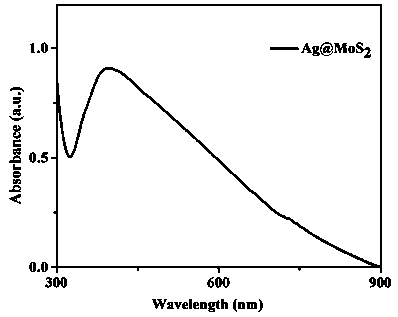

[0051] (a) MoS 2 Preparation of nanosheets

[0052] Add 800 mg of MoS to a 50 mL Schlenk tube 2 , Remove the air in the reaction tube with high-purity argon, then seal it, and slowly add 25 mL of n-butyllithium solution dropwise. After stirring at room temperature for 48 h, stop the reaction and let it stand for 2 to 4 h, remove the n-butyllithium solution in the upper part of the reaction tube, and convert the obtained single-layer or several-layer MoS 2 The nanosheets are dispersed in aqueous solution. Centrifugal purification to obtain a certain concentration of water-soluble MoS 2 Nanosheets.

[0053] (b) Preparation of reducing agent and stabilizer

[0054] Add 176.14 mg of ascorbic acid (AA) and 10 mL of ultrapure water to a 20 mL sample bottle to obtain a 100 mmol / L reducing agent solution; add 264.2 mg of sodium carboxymethylcellulose (CMC) to a 20 mL sample bottle , 10 mL of ultrapure water to obtain a 100 mmol / L stabilizer solution.

[0055] (c) Preparation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com