Technology for extracting tellurium dioxide from tellurium-containing smelting slag

A technology of tellurium dioxide and smelting slag, applied in the field of extracting tellurium dioxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

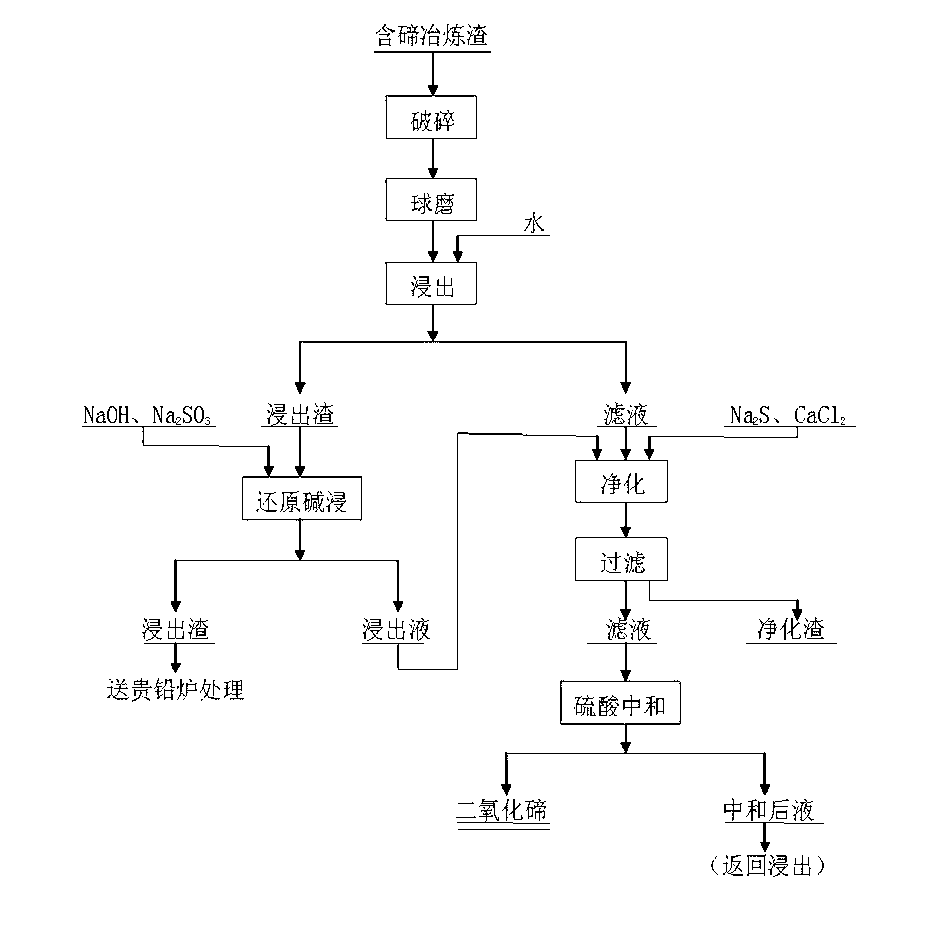

Image

Examples

example 1

[0035] Composition of tellurium-containing smelting slag: tellurium: 6.35%, bismuth: 43.38%, copper: 11.43%, lead: 8.54%, arsenic: 0.06%, antimony: 1.27%, selenium: 0.05%, silver: 1.4253%, gold: 1.5% g / t, silicon dioxide: 1-2%.

[0036](1) Take 100g of tellurium-containing smelting slag, add water according to the liquid-solid mass ratio of 3:1 to make slurry, control the temperature at 75°C, react for 2 hours, and the particle size is 200 mesh; immediately filter and separate the primary water immersion liquid and rich bismuth and copper , silver, gold leaching slag; obtain leaching slag 88.2g, tellurium-containing amount is 2.46%, bismuth-containing amount is 40.27%, copper-containing amount is 11.02%, and silver-containing amount is 1.367% in leaching slag;

[0037] (2) Add the primary water immersion residue obtained above into a mixed solution containing 30g / L sodium hydroxide and 10g / L sodium sulfite, under the condition of controlling the liquid-solid ratio to 3:1, the...

example 2

[0042] Composition of tellurium-containing smelting slag: tellurium: 6.35%, bismuth: 43.38%, copper: 11.43%, lead: 8.54%, arsenic: 0.06%, antimony: 1.27%, selenium: 0.05%, silver: 1.4253%, gold: 1.5% g / t, silicon dioxide: 1-2%.

[0043] (1) Take 100g of tellurium-containing smelting slag, add water according to the liquid-solid mass ratio of 4:1 to make slurry, control the temperature at 90°C, react for 3 hours, and the particle size is 260 mesh; immediately filter and separate the primary water immersion liquid and rich bismuth and copper , silver, gold leaching slag; obtain leaching slag 84.5g, contain tellurium in the leaching slag and be 1.96%, bismuth-containing amount is 46.48%, copper-containing amount is 12.67%, and silver-containing amount is 1.514%;

[0044] (2) Add the primary water immersion residue obtained above into a mixed solution containing 50g / L sodium hydroxide and 20g / L sodium sulfite, under the condition that the liquid-solid ratio is controlled at 4:1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com